If you’re a maintenance manager or a process engineer, you probably already know how versatile air-operated double-diaphragm (AODD) pumps are.

If you’re a maintenance manager or a process engineer, you probably already know how versatile air-operated double-diaphragm (AODD) pumps are.

As long as an AODD pump can accommodate a system’s pressure and flow, it will work in nearly any application—from food to chemicals, to oil and gas, and more. Plus, AODD pumps can handle abrasives, slurries, and solids. They are submersible and can run dry without being damaged, unlike mechanical pumps.

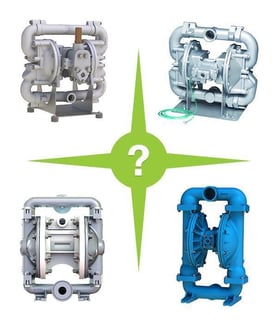

Although AODD pumps are simple to operate, no two facilities or systems are the same and there are an array of options, so choosing the right pump for your next project requires some background information.

Let’s take a look at the process for deciding which type of AODD pump is right for your project. You’ll need to know several key pieces of information, including chemical compatibility, flow, and friction loss. In some cases, market-specific details may also play a role in your pump selection.

1. Chemical compatibility

Step one when specifying a pump is to ensure the liquid you’re pumping is chemically compatible with your pump’s materials. In other words, chemical compatibility should drive the materials you select for your pump.

If the substance you’re pumping is not chemically compatible with your pump’s construction (metallic vs. non-metallic) or elastomer materials, your pump may experience premature failure, corrosion, or other inconvenient and possibly unsafe maintenance issues.

How to determine chemical compatibility

The easiest way to identify the chemical compatibility of your liquid and pump is to reference the pump manufacturer’s chemical compatibility guide. SANDPIPER’s Chem Guide is a searchable online resource for learning the chemical compatibility of many common liquids used in chemical, paint, industrial, food processing, and other applications.

2. Flow

After understanding the compatibility of your liquid and AODD pump materials, it’s time to consider flow. Your flow requirement (in gallons per minute) will help you determine the size of your pump—whether you can go small with a 1/4" pump or if you need to go all the way up to a 3” pump. On the low end, a 1/4" unit can pump 7 gpm maximum, while a 3” model can pump 280 gpm maximum.

How to find flow information

Every SANDPIPER pump has a data sheet, which lists the maximum flow capacity in gpm ranging up to 280 gpm.

3. Friction loss

Another factor you must account for when choosing a pump is friction loss. Friction loss causes a drop in psi at the end of the line due to the liquid’s interaction with the internal walls of the pipe it’s being pumped through. For example, a 3” pump with a 3” pipe would have less friction loss than a 1” pump with a 1” pipe.

In terms of pressure, AODD pumps typically max out at 125 psi. Before selecting a pump, calculate all the factors that contribute to friction loss (measured in feet of liquid) to ensure you’re not exceeding 125 psi. These factors include the number of elbows, valves, pipe size, and pipe length. After collecting that information and calculating friction loss, check it against the performance curve of the pump you’re considering to ensure you’re within range. Remember, if your pump is running fast, you may want to think about going up to the next size to improve the longevity of the pump’s components.

How to determine friction loss

Consult a resource like the Cameron Hydraulic Data Book or find an online friction loss calculator to determine friction loss. Check each pump’s data sheet to see its performance curve. If you need help understanding friction loss, contact your local distributor or the SANDPIPER application engineering team.

4. Market-specific considerations

Beyond chemical resistance, flow, and friction loss, you may have market-specific considerations to help you determine what type of pump you need for your next project. Here are a few markets that have factors that may narrow down your decision.

Market: Lithium battery recycling

Recommended pumps: Heavy-duty flap valve pumps

Why: Heavy-duty flap valve pumps are ideal for the abrasive slurries, non-suspended, and line-size solids found in lithium-ion battery recycling.

Market: Lithium mining and processing

Recommended pumps: 3" stainless steel metallic AODD pumps, such as the S30

Why: This size can handle the combination of the vacuum conditions and the high flow rate required in lithium carbonate drying operations.

Market: Oil & gas

Recommended pumps: G-Series dual-power pumps

Why: SANDPIPER’s G-Series dual-power pumps run off of natural gas rather than compressed air and carry the most stringent certifications for safety and reliability for oil and gas applications.

Market: Chemical

Recommended pumps: Various Pumps

Why: With the wide range of chemical applications, Sandpiper’s heavy duty pumps across a range of materials and flexible configurations can be matched to your specific manufacturing and treatment needs.

Market: Food & Beverage/Sanitary

Recommended pumps: Various FDA-compliant pumps

Why: Depending on the application, SANDPIPER offers a wide range of construction options, including FDA-compliant materials such as 316 stainless steel and non-colored polypropylene.

In addition to the standard decision-making process and market-specific factors detailed above, cost is likely a factor when choosing an AODD pump or making any investment in your facility. That said, the most affordable approach is to carefully choose the right pump for your application; otherwise, your maintenance team may have to spend undue time and energy repairing an improperly specified pump.

For more help choosing an AODD pump, check out the additional resources SANDPIPER offers, or contact us anytime with questions.