The global pulp and paper markets continue to experience aggressive growth as the consumption of pulp and paper products increases annually. Meeting this demand is extremely challenging due to the wide variety of processing needs from raw lumber and pulp processing to finished product production of vastly different products as seen in some of the examples below:

- Paperboard

- Cardboard boxes and cartons

- Tissue paper

- Diapers

- Personal hygiene products

- Containerboard

- Bags and envelopes

The production levels are extremely large and can be very demanding, given the daily challenge of heavy slurries and dense solids common to this processing environment. Choosing the right pump is mission-critical in order to maintain production yields and avoid costly downtime.

SANDPIPER – YOUR TRUSTED PARTNER FOR LIFE

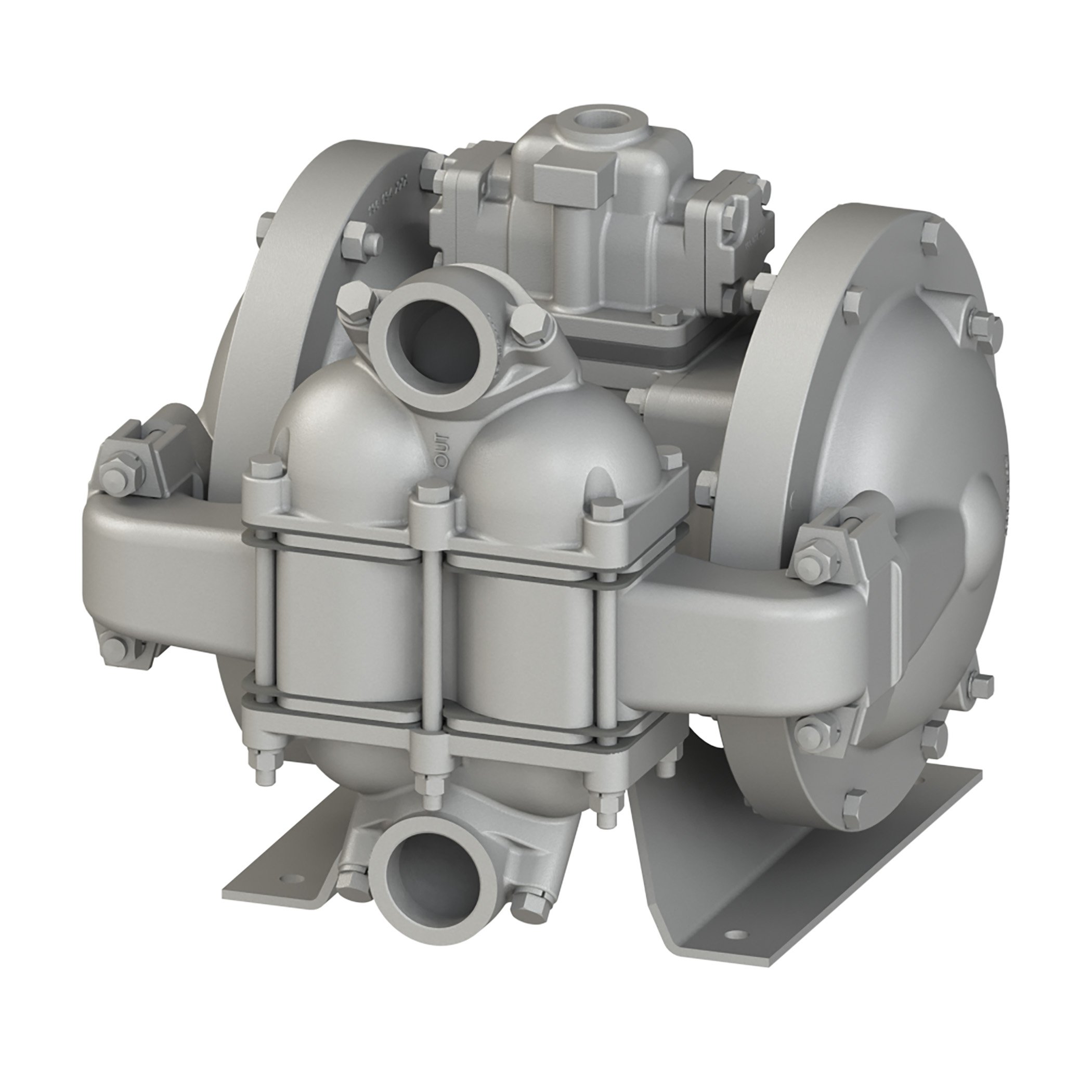

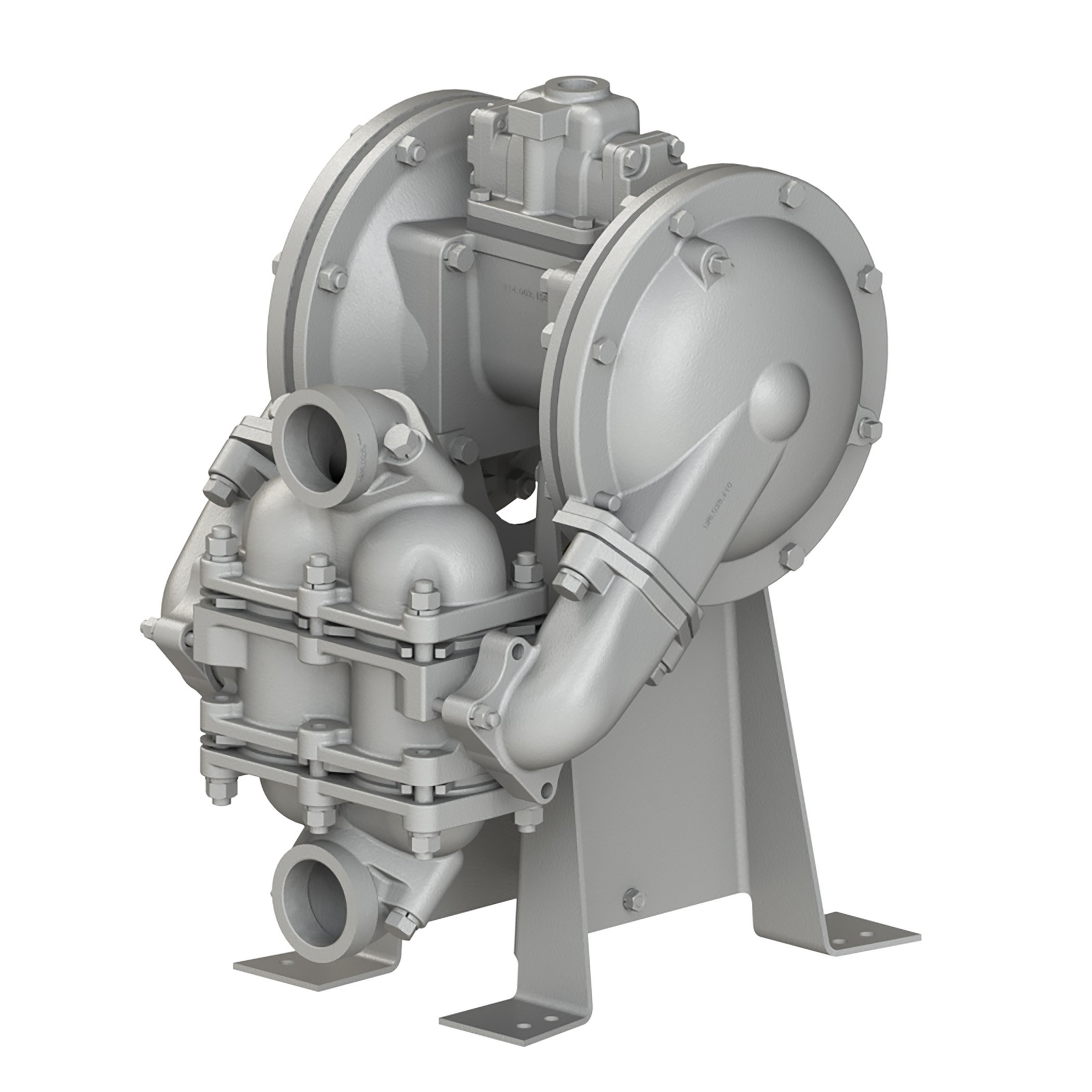

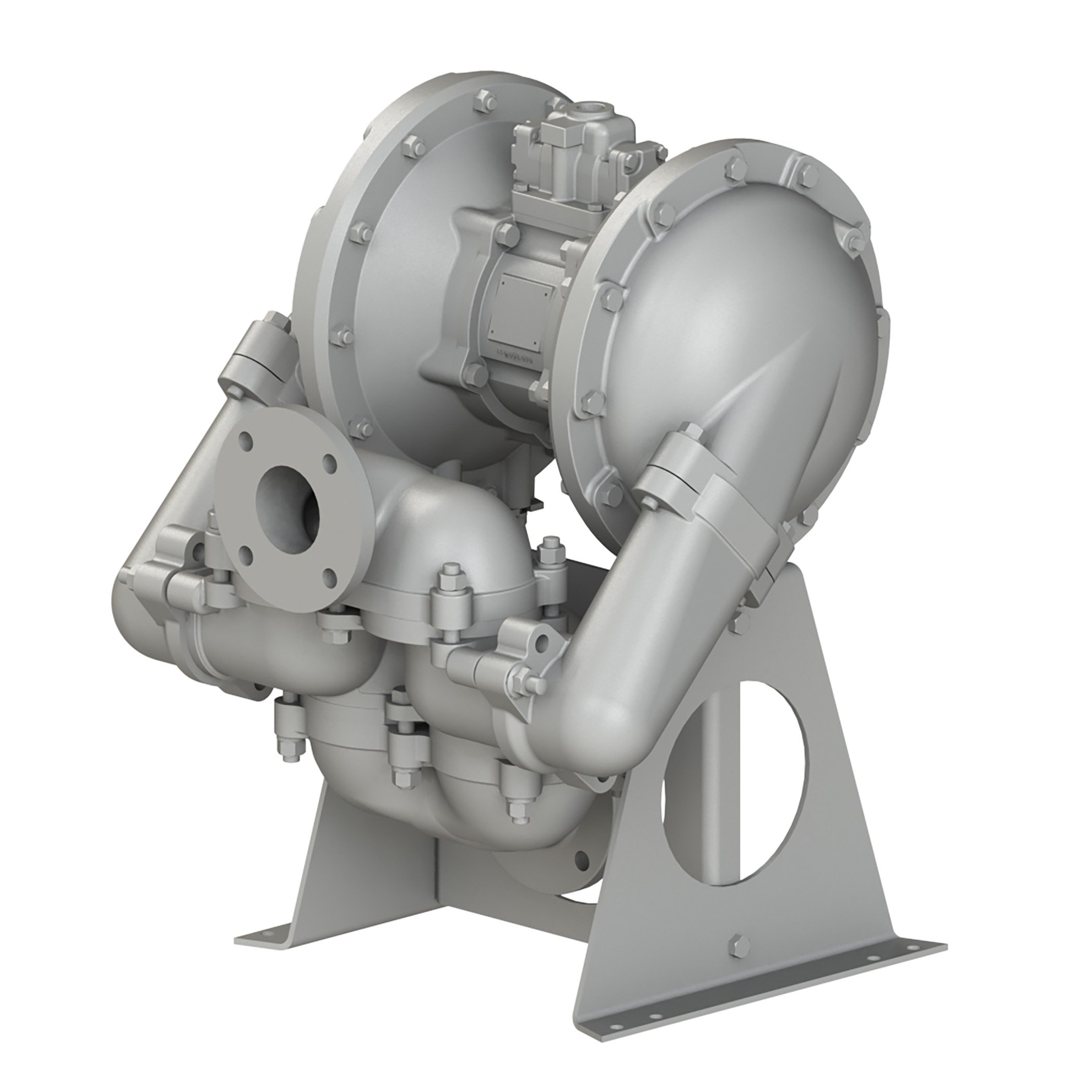

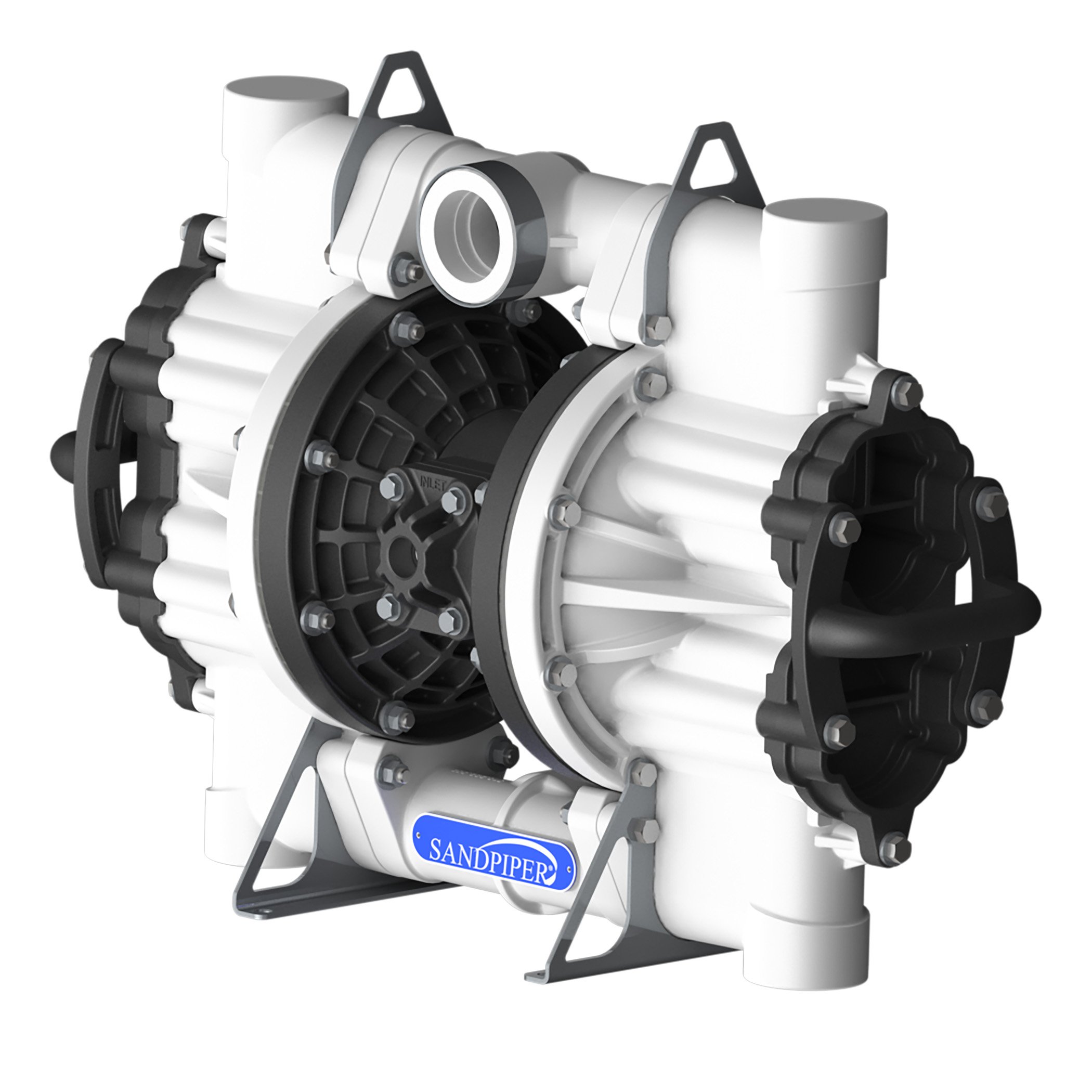

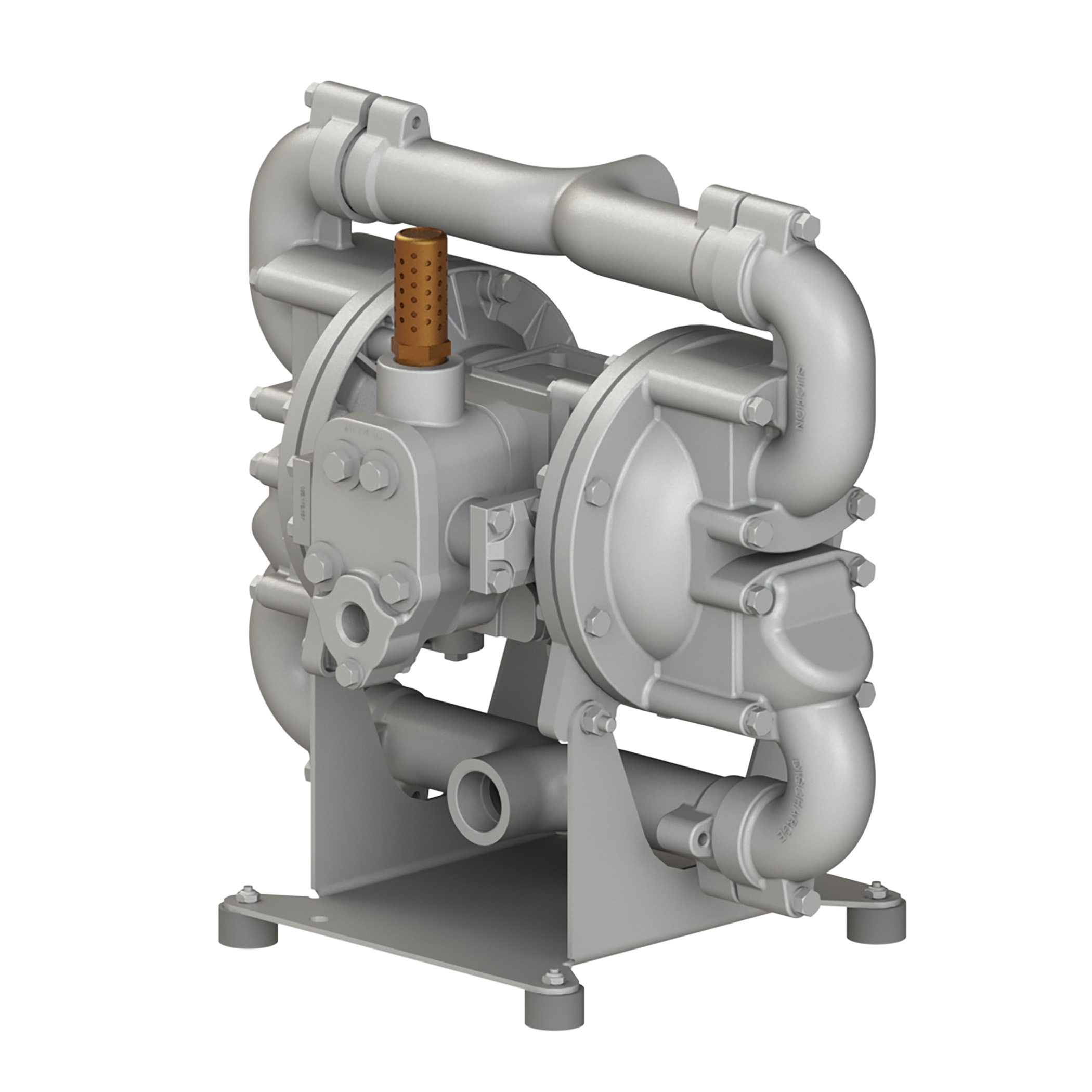

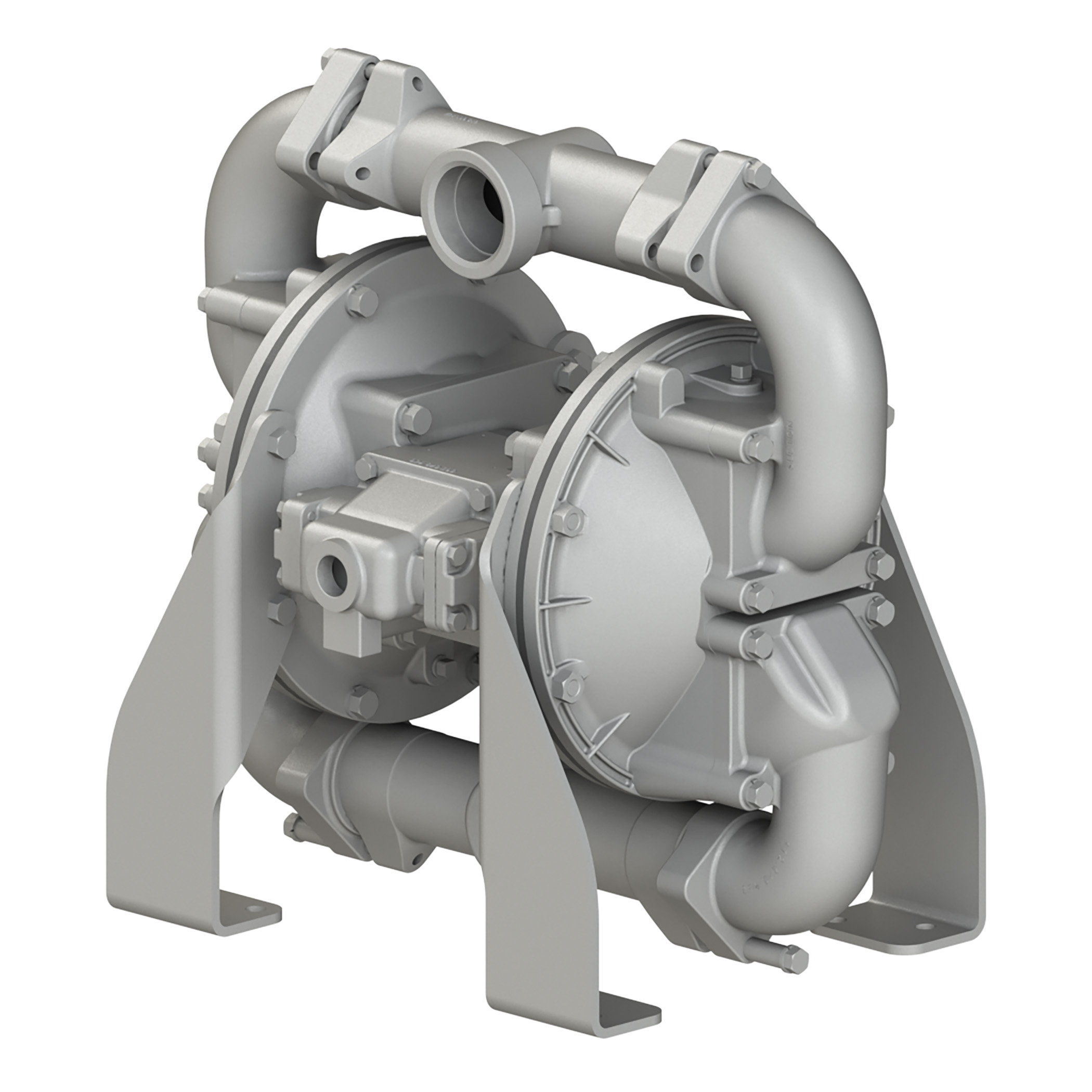

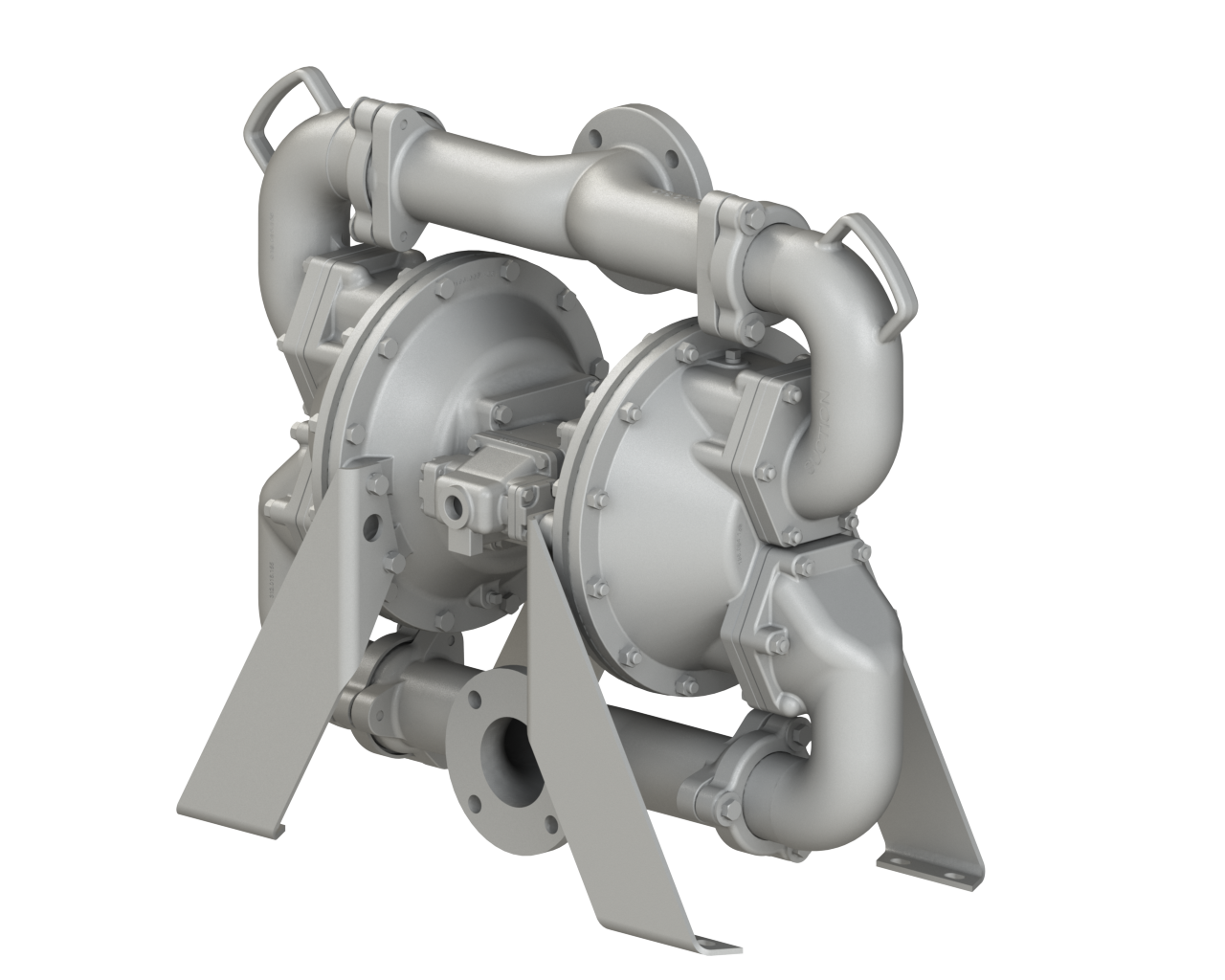

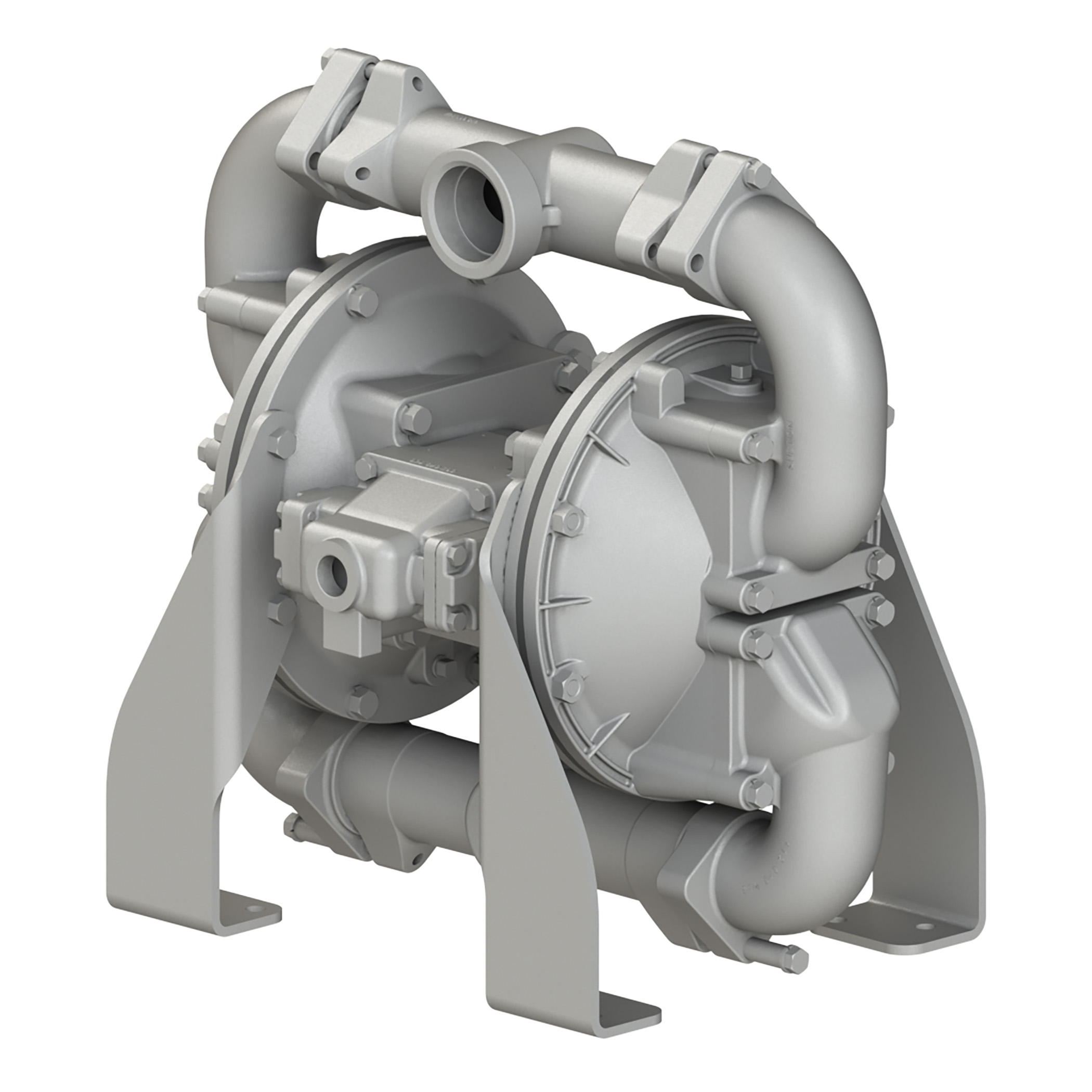

SANDPIPER is the leading air-operated double-diaphragm (AODD) pumps manufacturer of the toughest, longest-lasting products on the market. Our AODD pumps for over 55 years have been 100% tested before allowed to leave our factory and are backed with a best-in-class warranty and can be trusted to solve your critical pulp and paper application challenges.

SANDPIPER AODD pumps offers the broadest range of pumping options:

- Thick-walled construction for durability; bolted design to eliminate leakage

- No-stall air valve design provides superior operating performance

- Flap valve and ball valve pumps with a variety of porting options for maximum flexibility

- Containment duty pumps with both visual and electronic leak detection options for best-in-class leak detection

- Industry-leading maximum flow rates combined with the lowest air consumption available

- Variety of materials from stainless steel to polypropylene, give maximum options for handling caustic processing chemicals

- Externally serviceable design makes maintenance easy and cost-effective

- Able to self-prime and run dry, combined with extremely accurate flow rates, means less downtime

Trust us as your partner in finding optimum pumping solutions for your pulp and paper needs with high-quality, cost-effective products. Our team of engineering experts will find the ideal pump to meet your specific application, and our after-sales support will keep your systems performing at the highest level possible.

COMMONLY USED AODD PULP AND PAPER APPLICATIONS

- Loading/unloading/transfer: Chemical transfer, abrasive fluid movement, solids and slurry handling

- Sump/wastewater: Heavy sludge and line-size solids

- Process/manufacturing: Caustic chemical pumping, bleaches, pH adjustment, inks, adhesives, wood treatment additives, calcium carbonate, acids

- Utility (Portable): general pumping across processing facility

- Box operations: Glue, starch, caustic soda for ink processing, viscous and abrasive bonding resins

- Batching: processes across the transformation of raw wood and paper to finished stock and corrugated materials

- Cleaning: pre- or post- processes with harsh chemical cleaners are used to eliminate batch-to-batch contamination

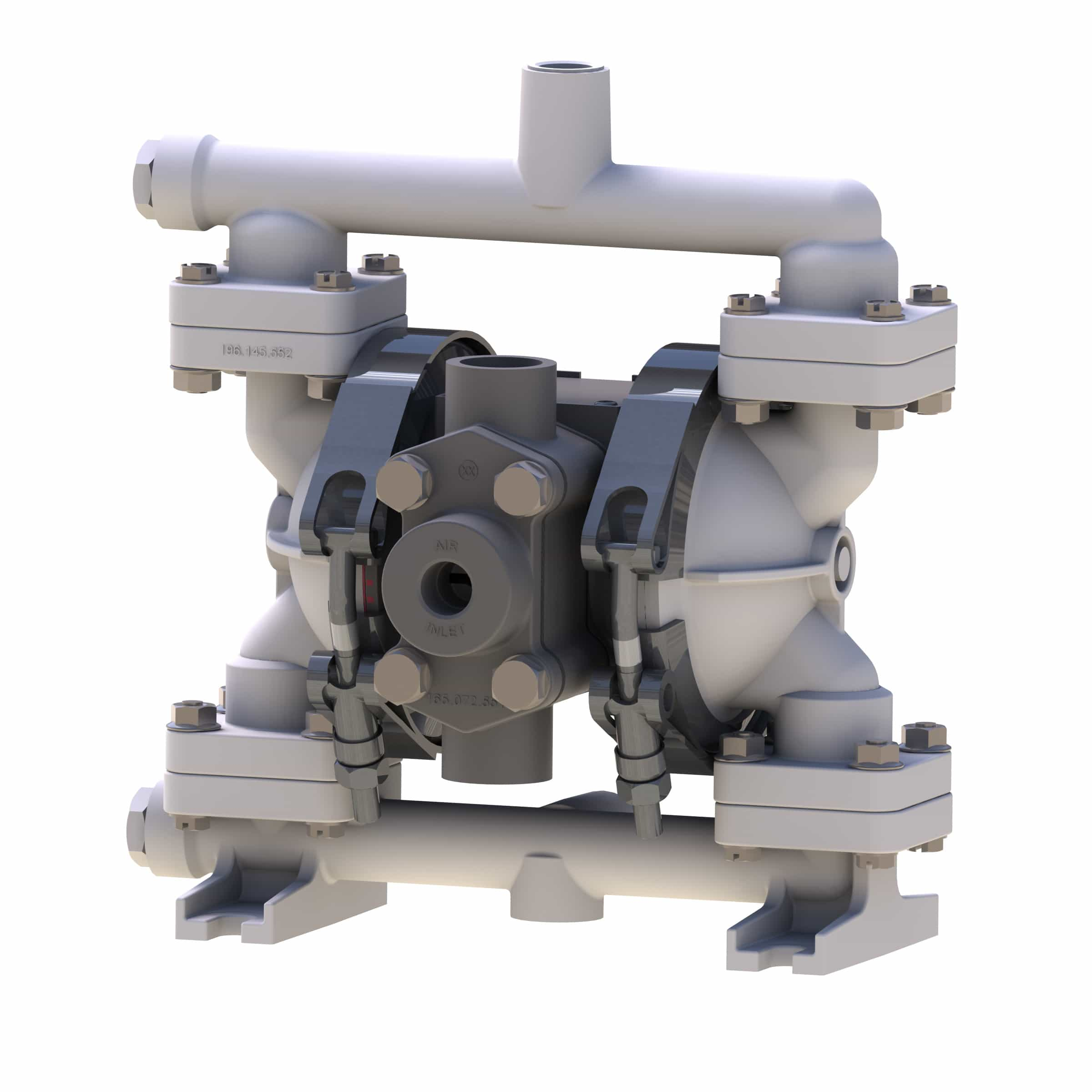

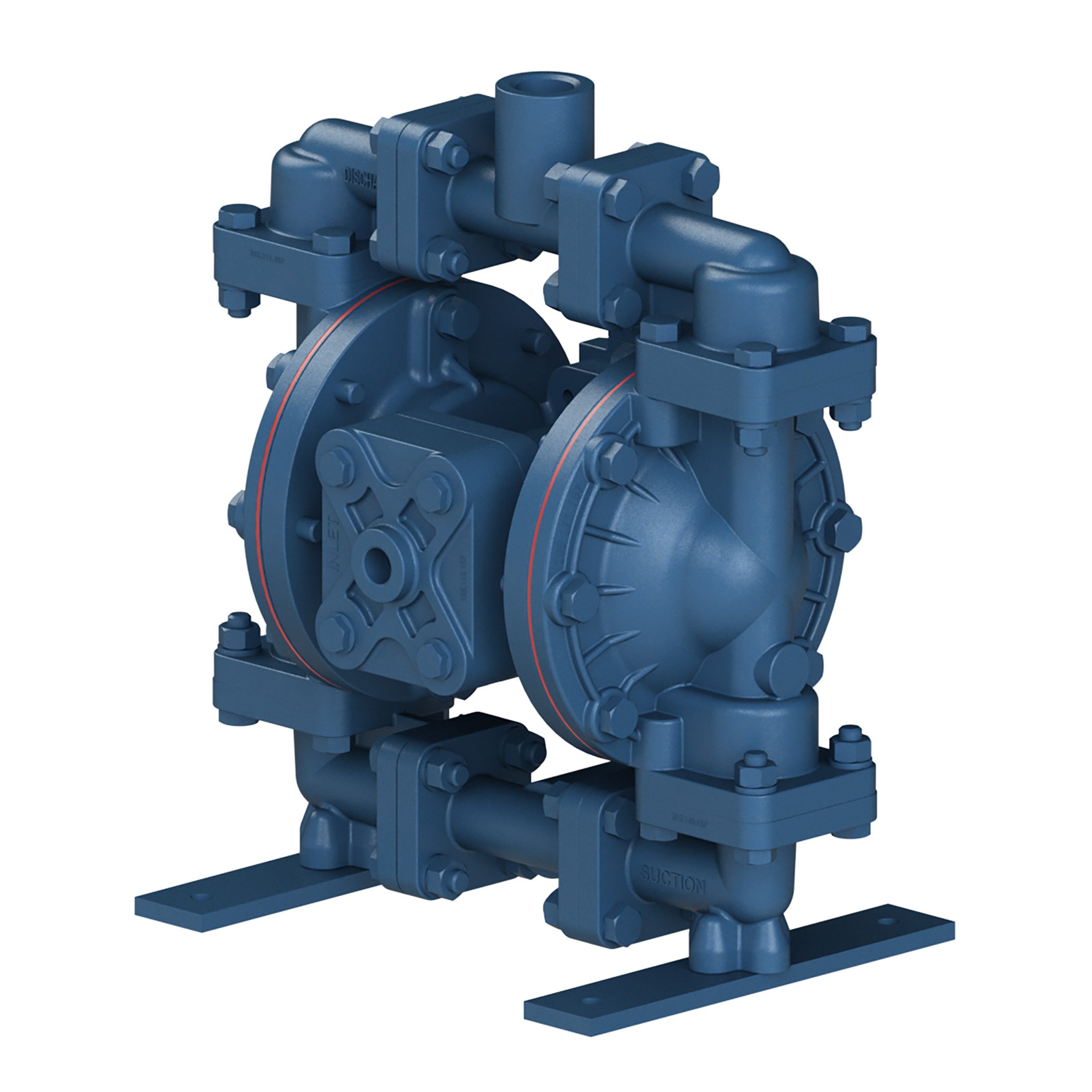

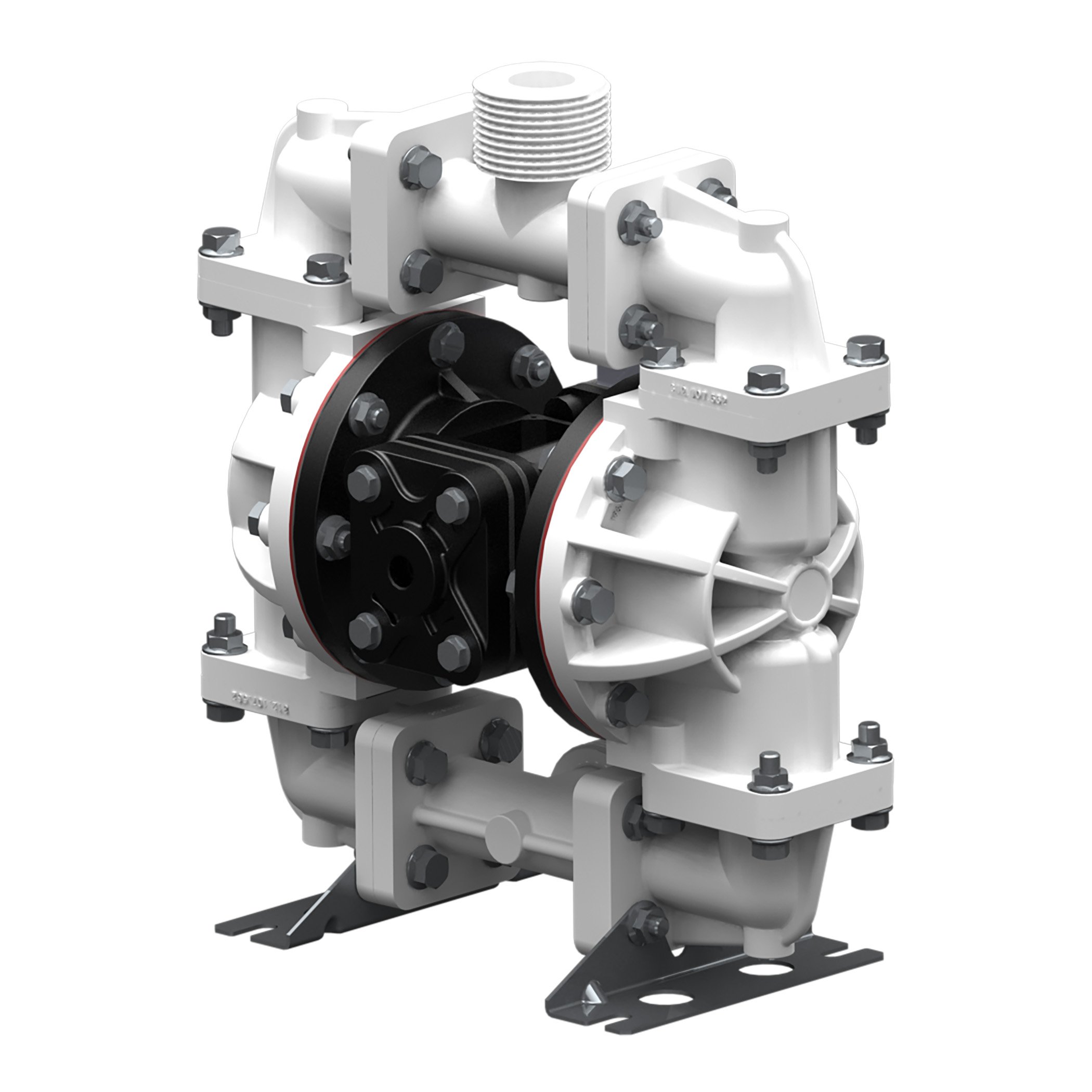

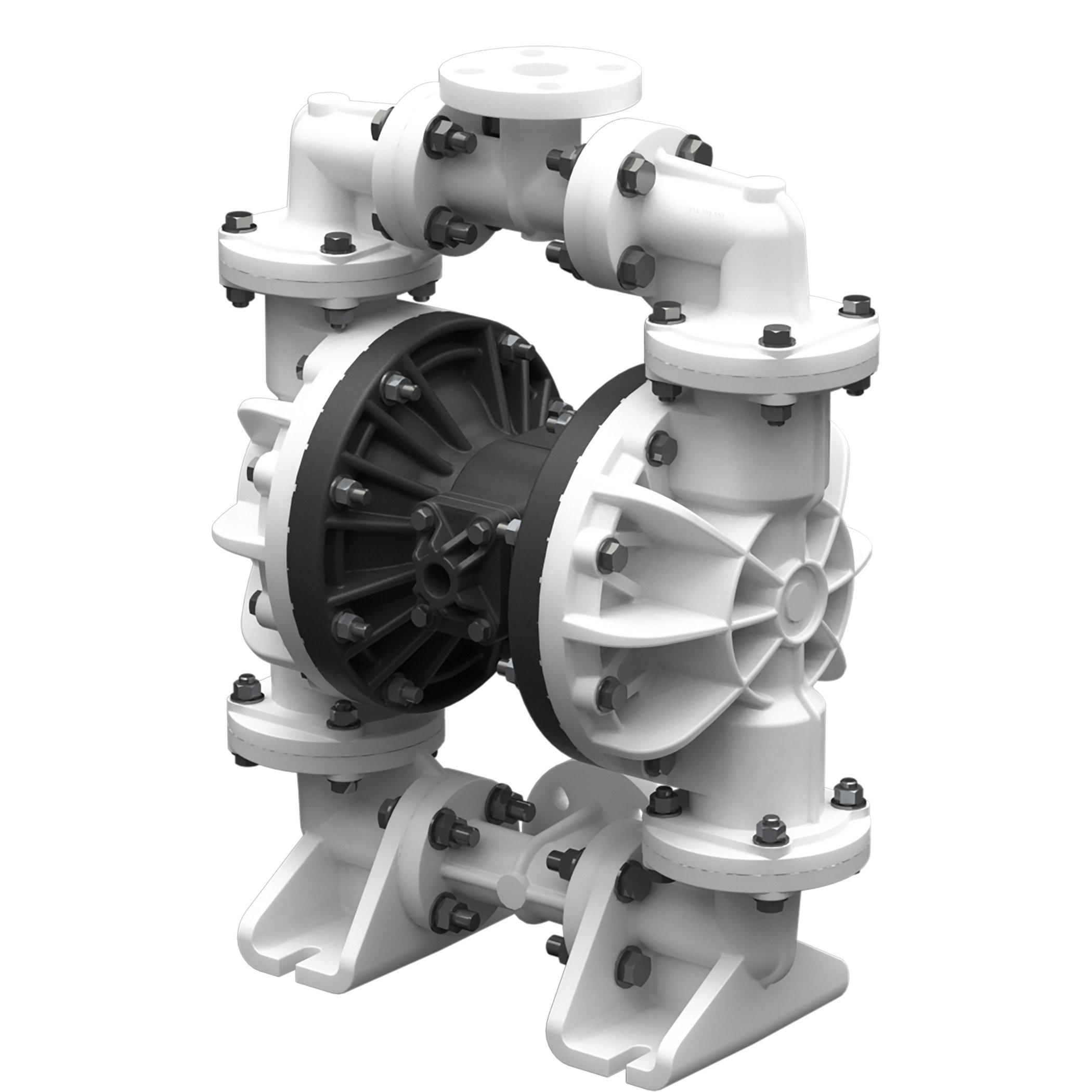

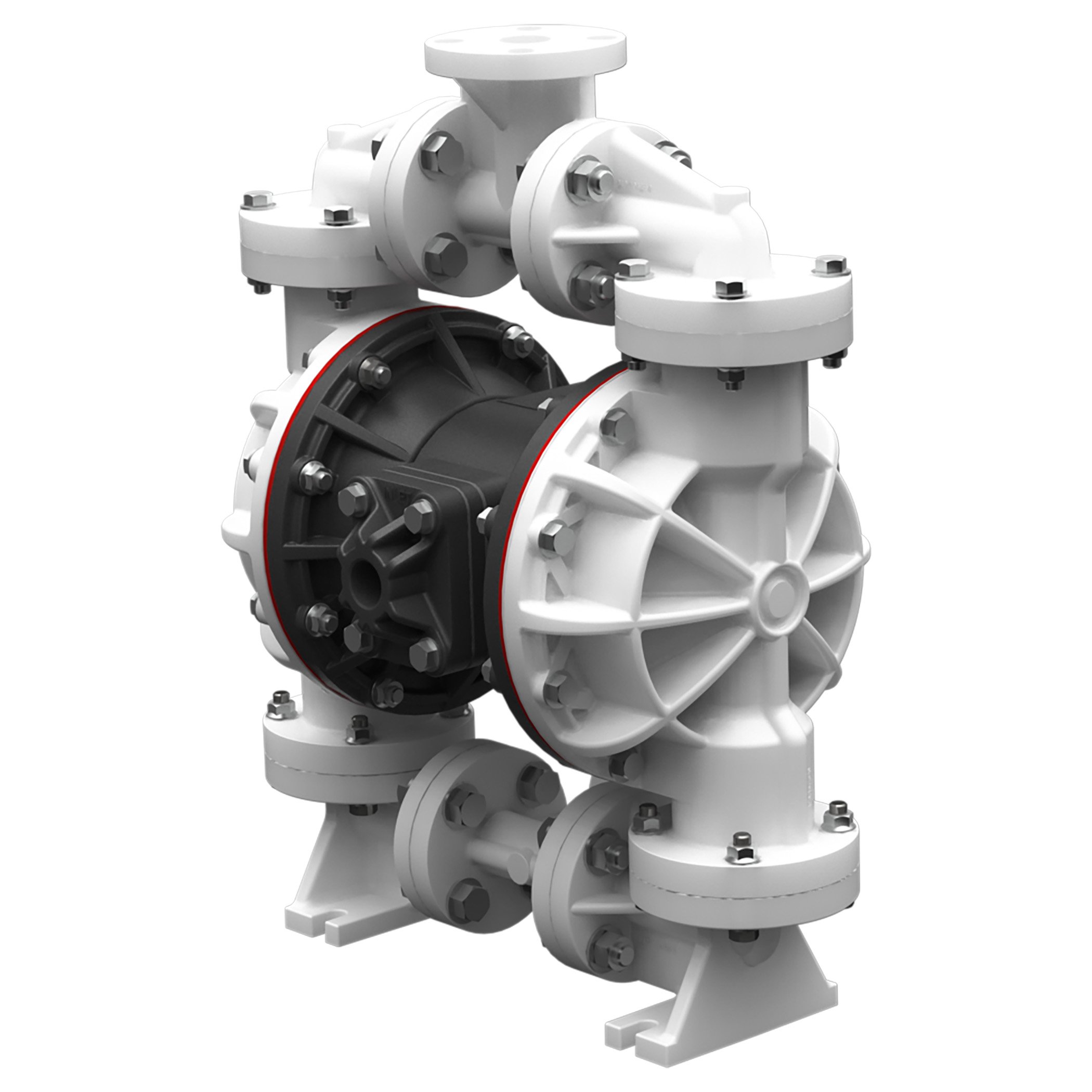

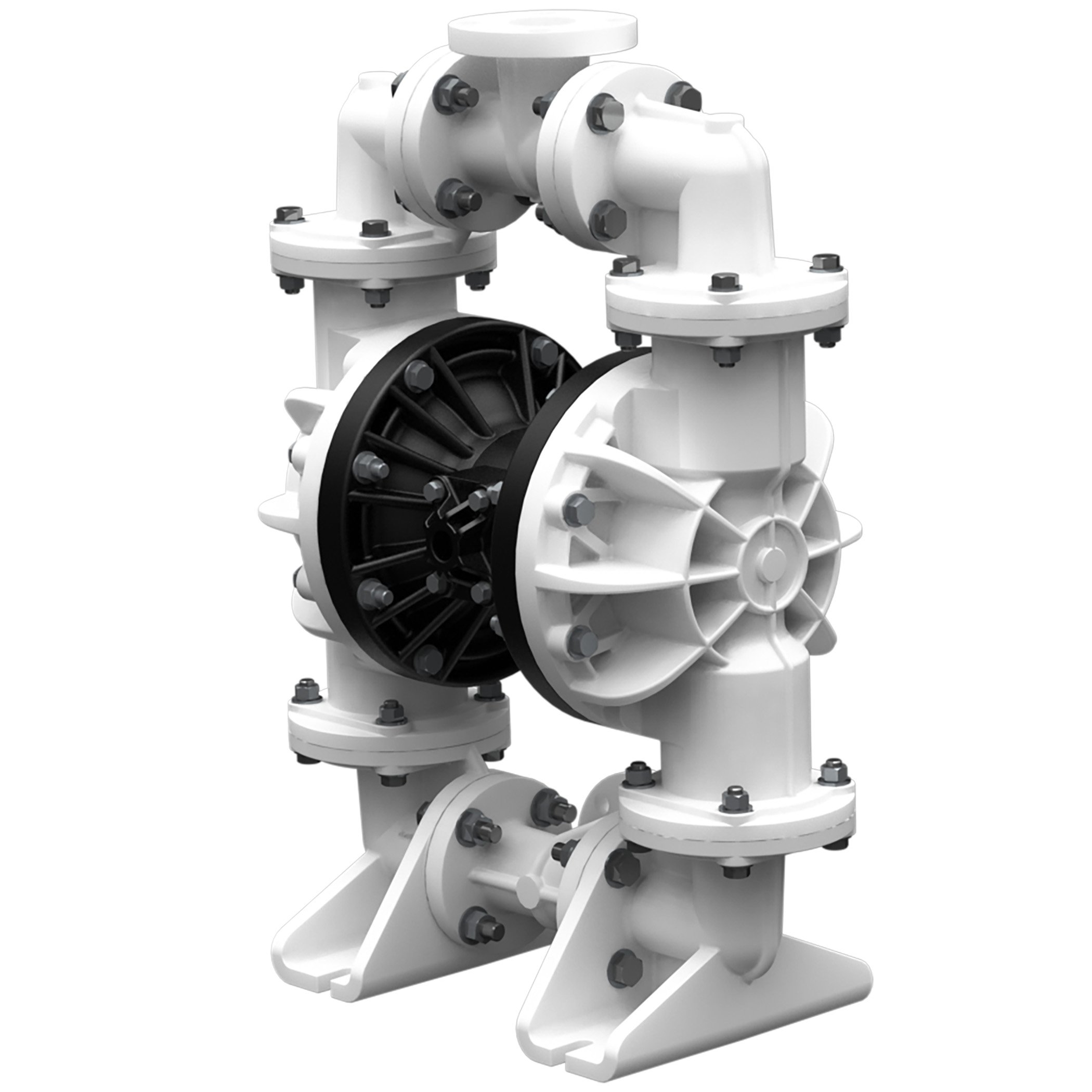

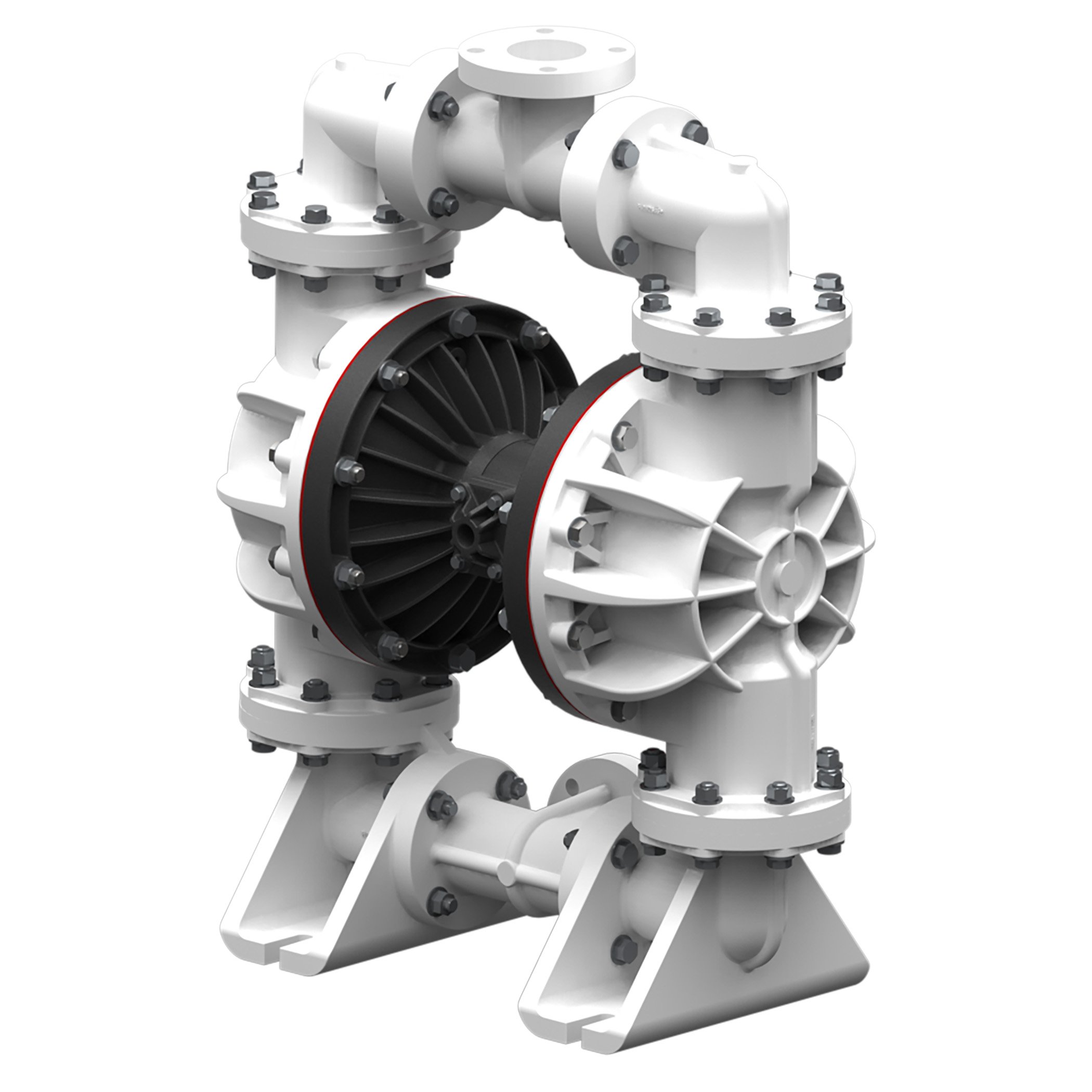

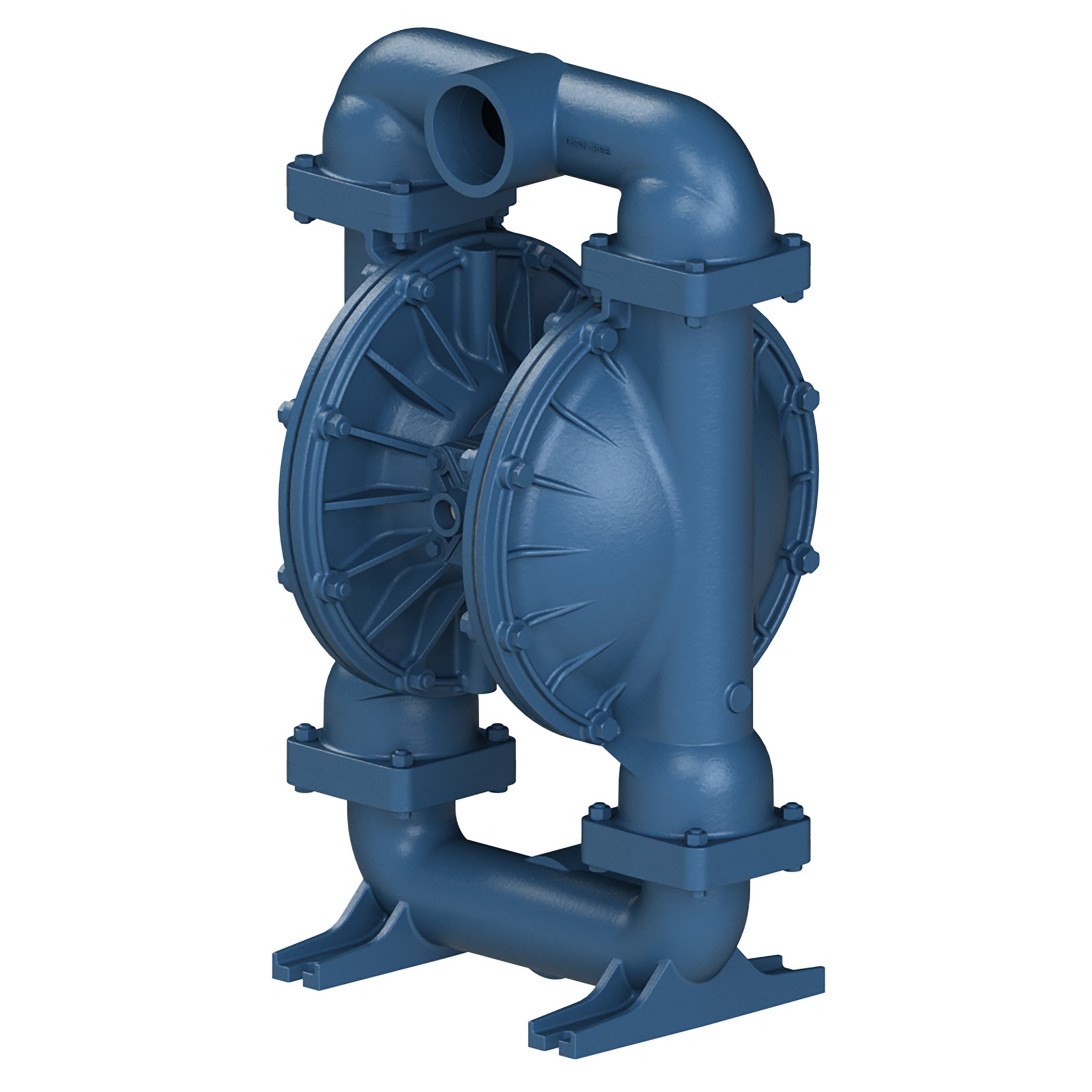

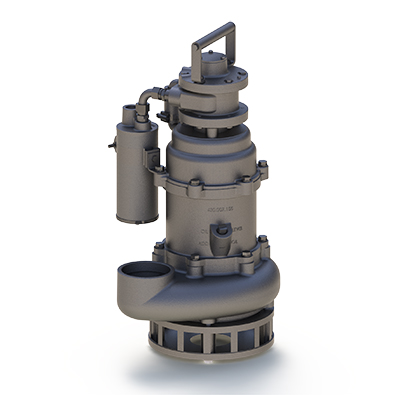

COMMONLY USED SANDPIPER AODD PUMPS IN THE PULP AND PAPER INDUSTRY

Click on each pump below to view additional pump details.

Learn more about certifications available and why it’s important to ground your pump.

To determine the chemical compatibility of these pumps with your application, please refer to our Chemical Compatibility Guide.