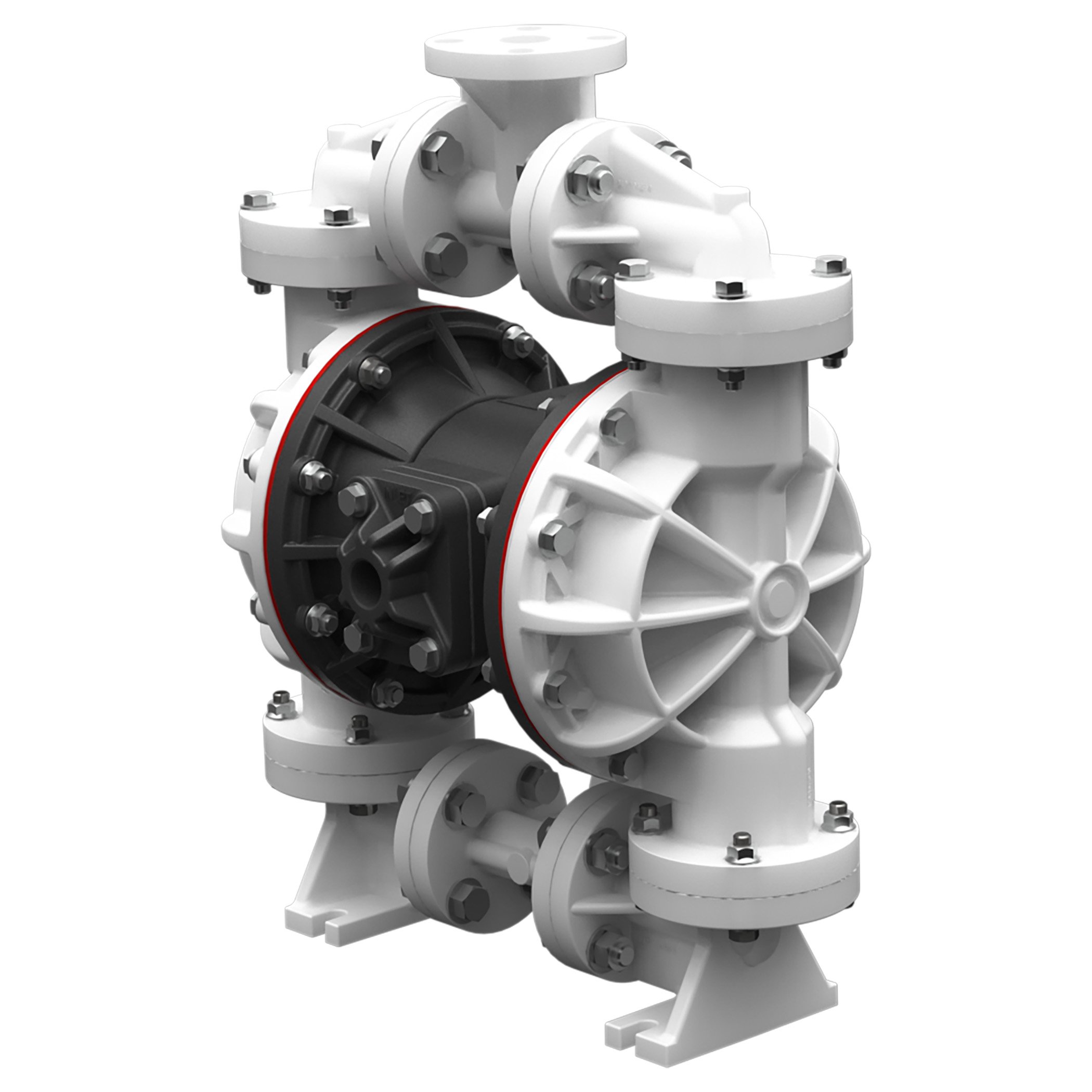

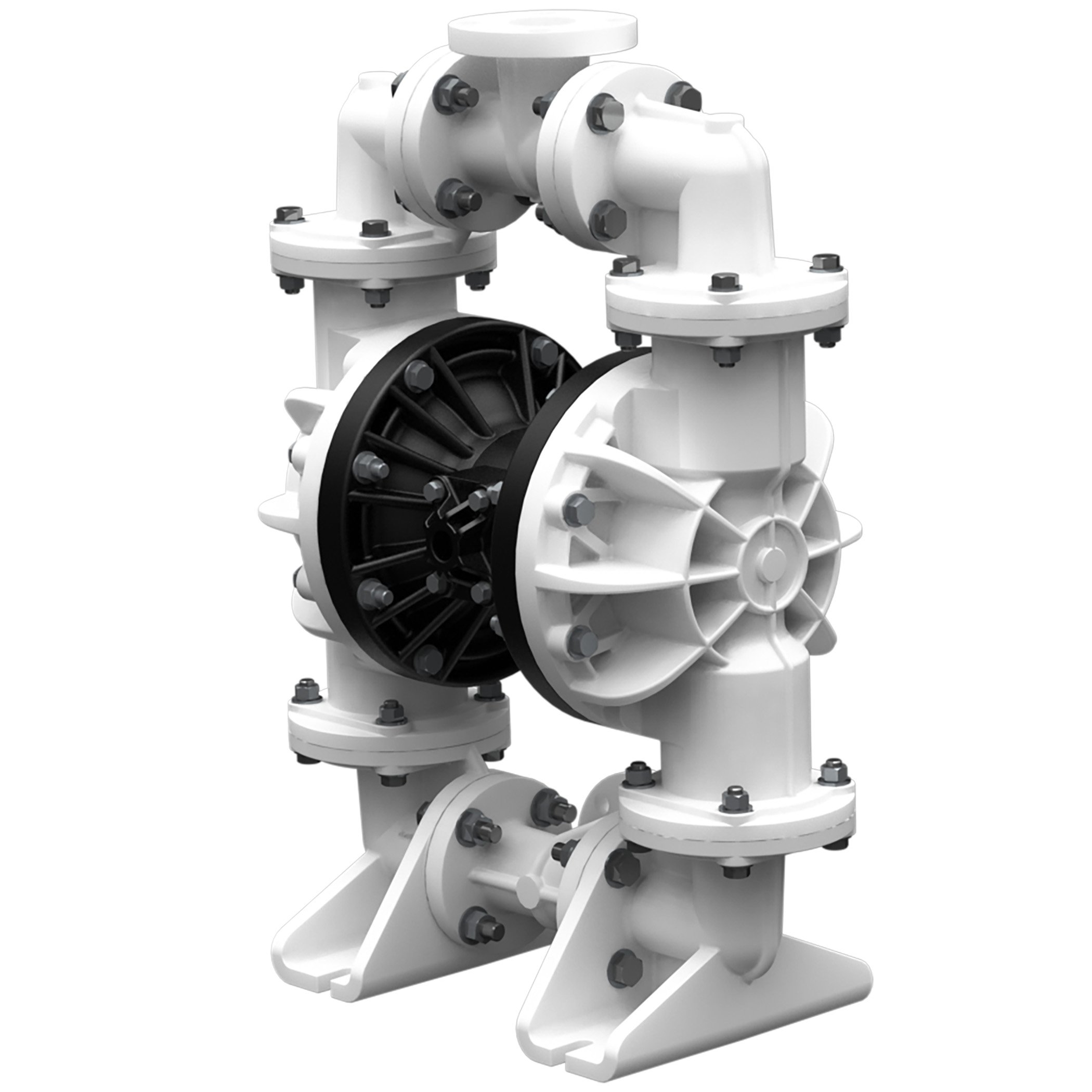

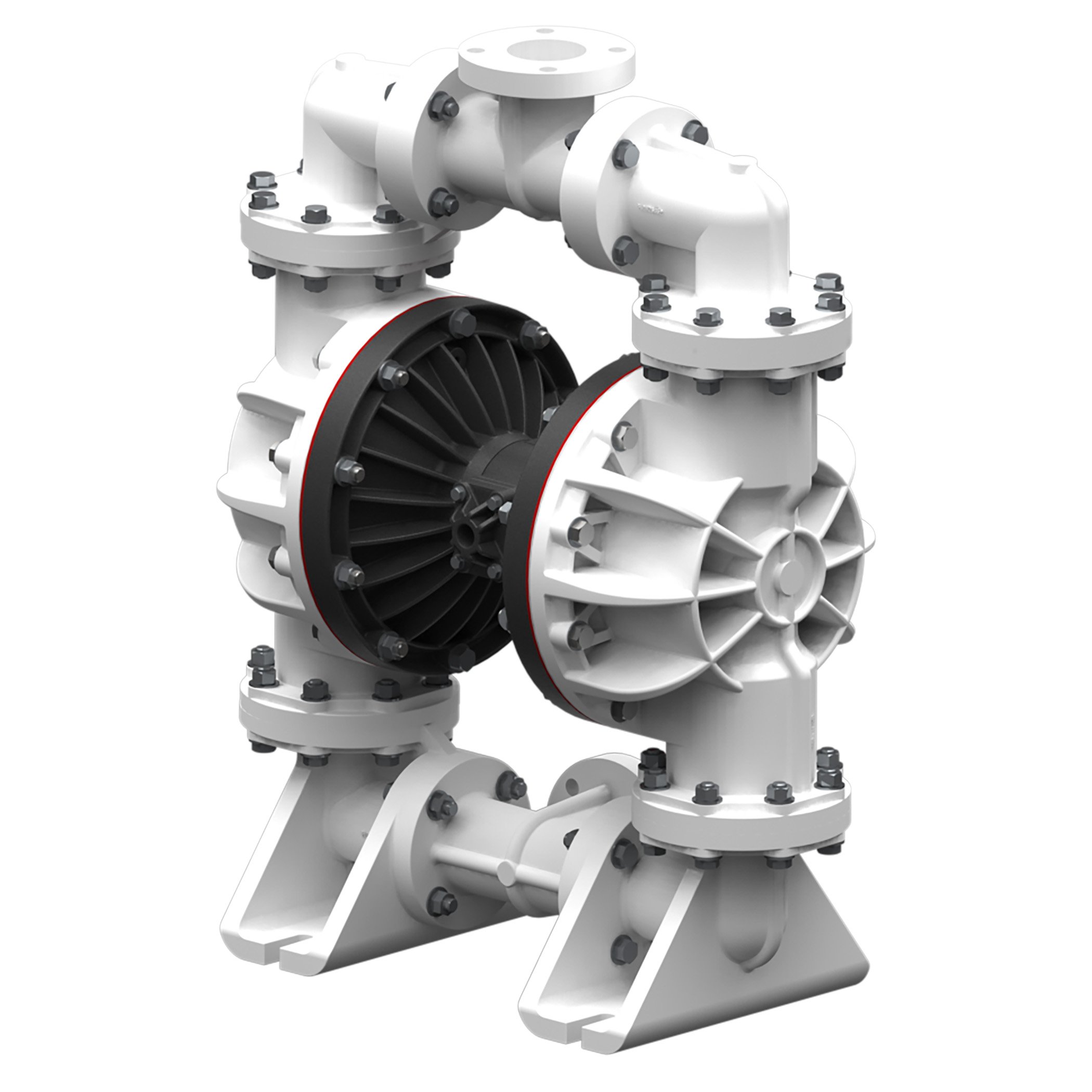

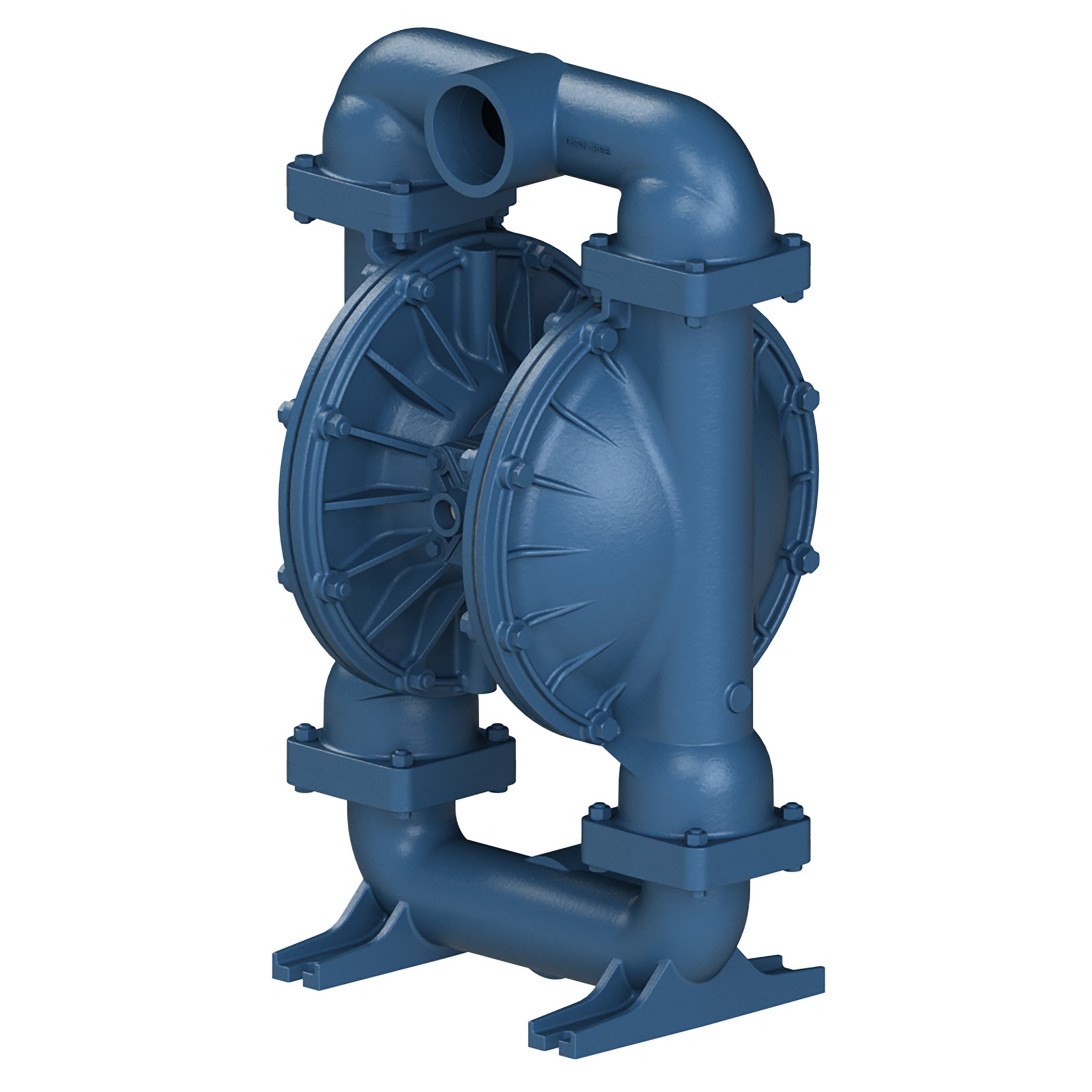

Containment Duty Pumps

For hazardous, corrosive, and dangerous fluids where safety is critical.

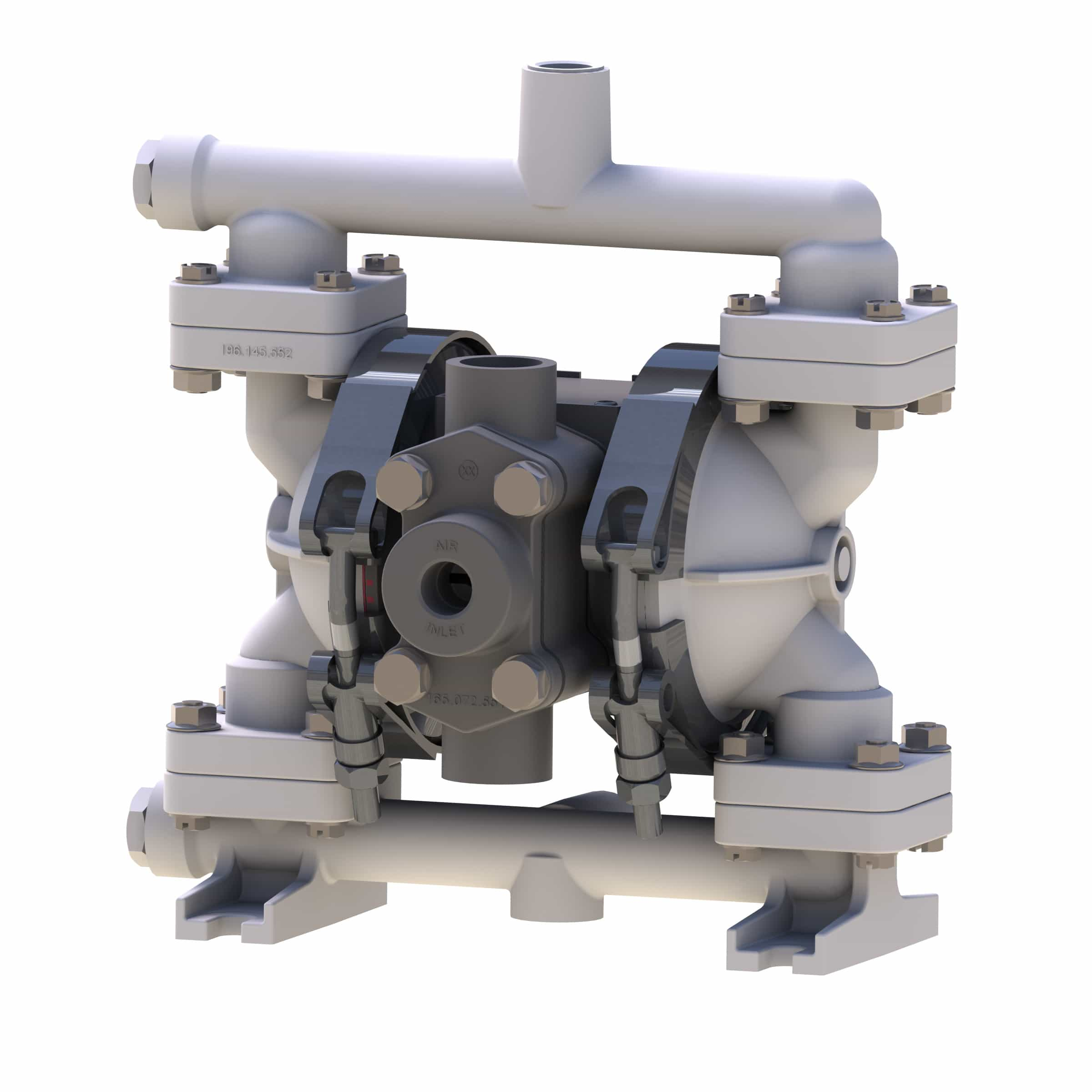

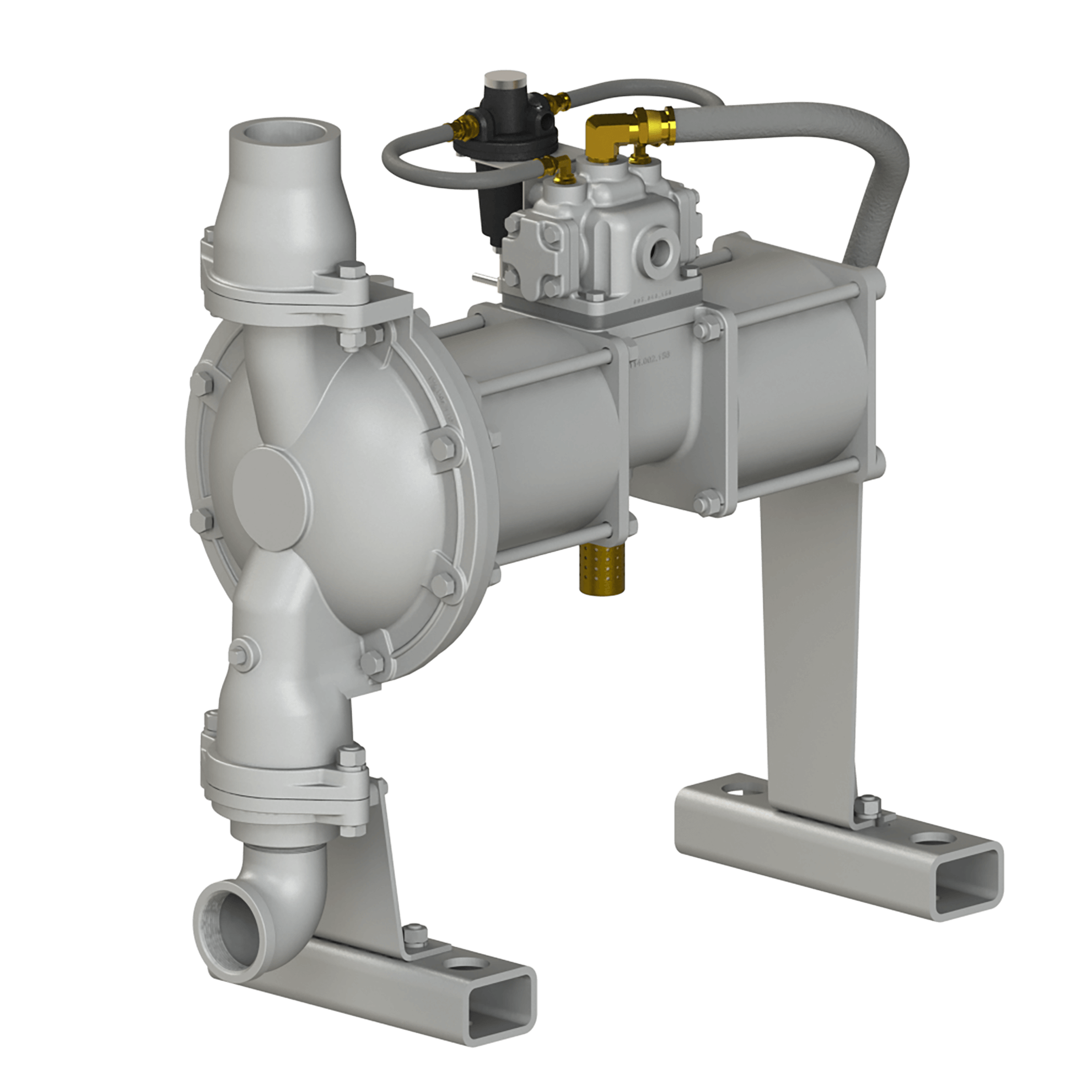

Specialty Pumps

For FDA and sanitary, high-pressure, gas-operated, submersible, EODD, and other unique applications.

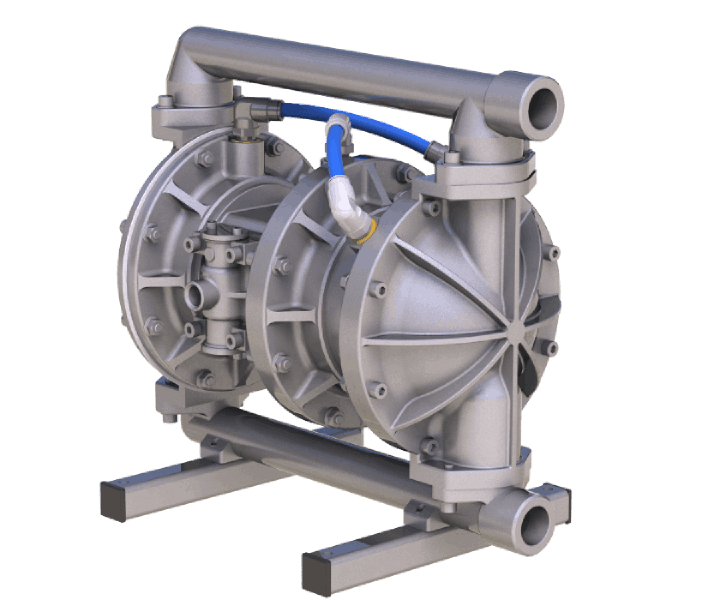

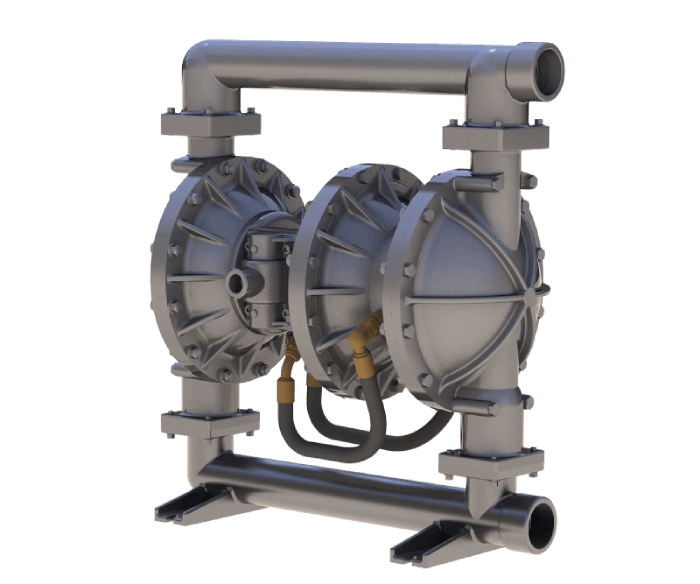

Featured Pumps

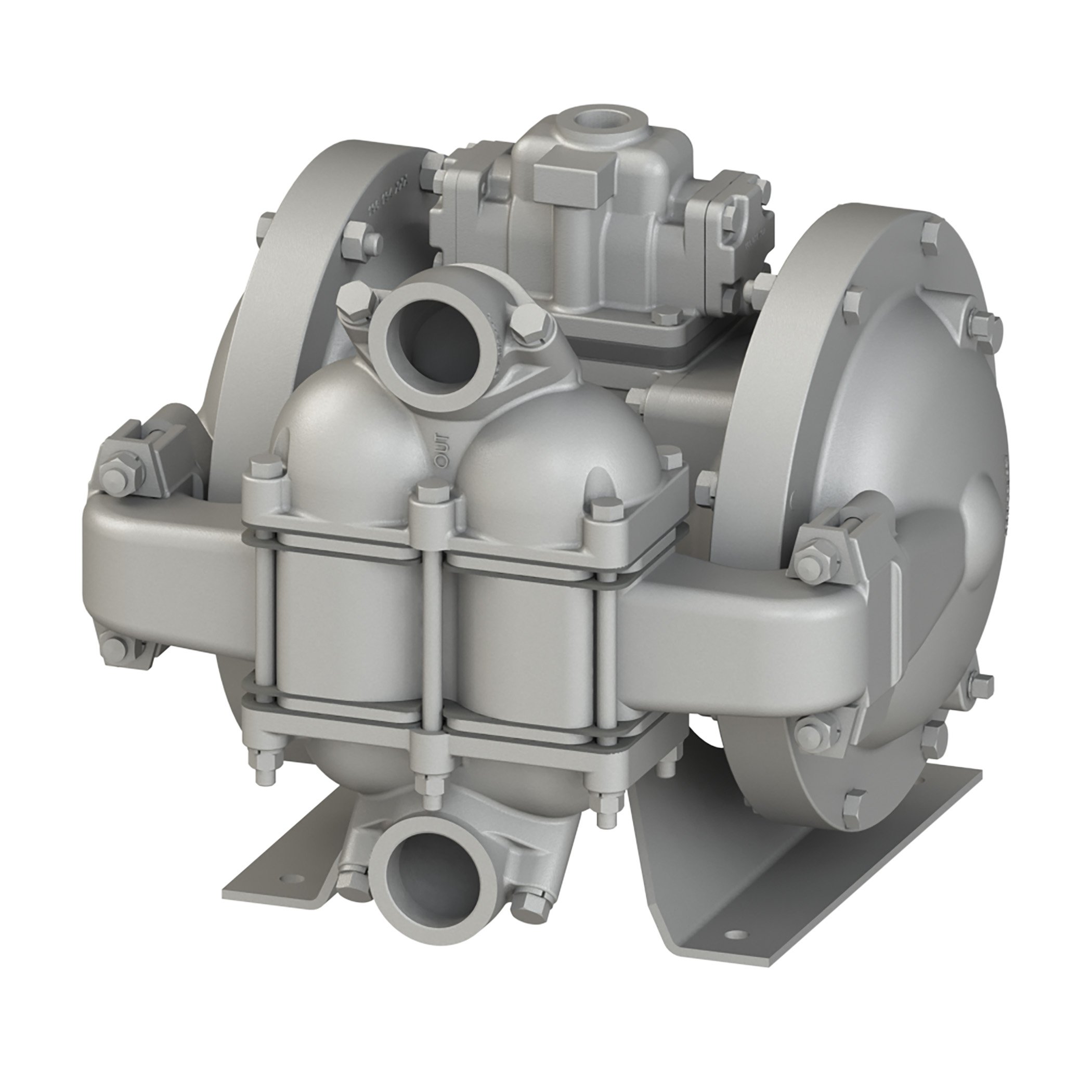

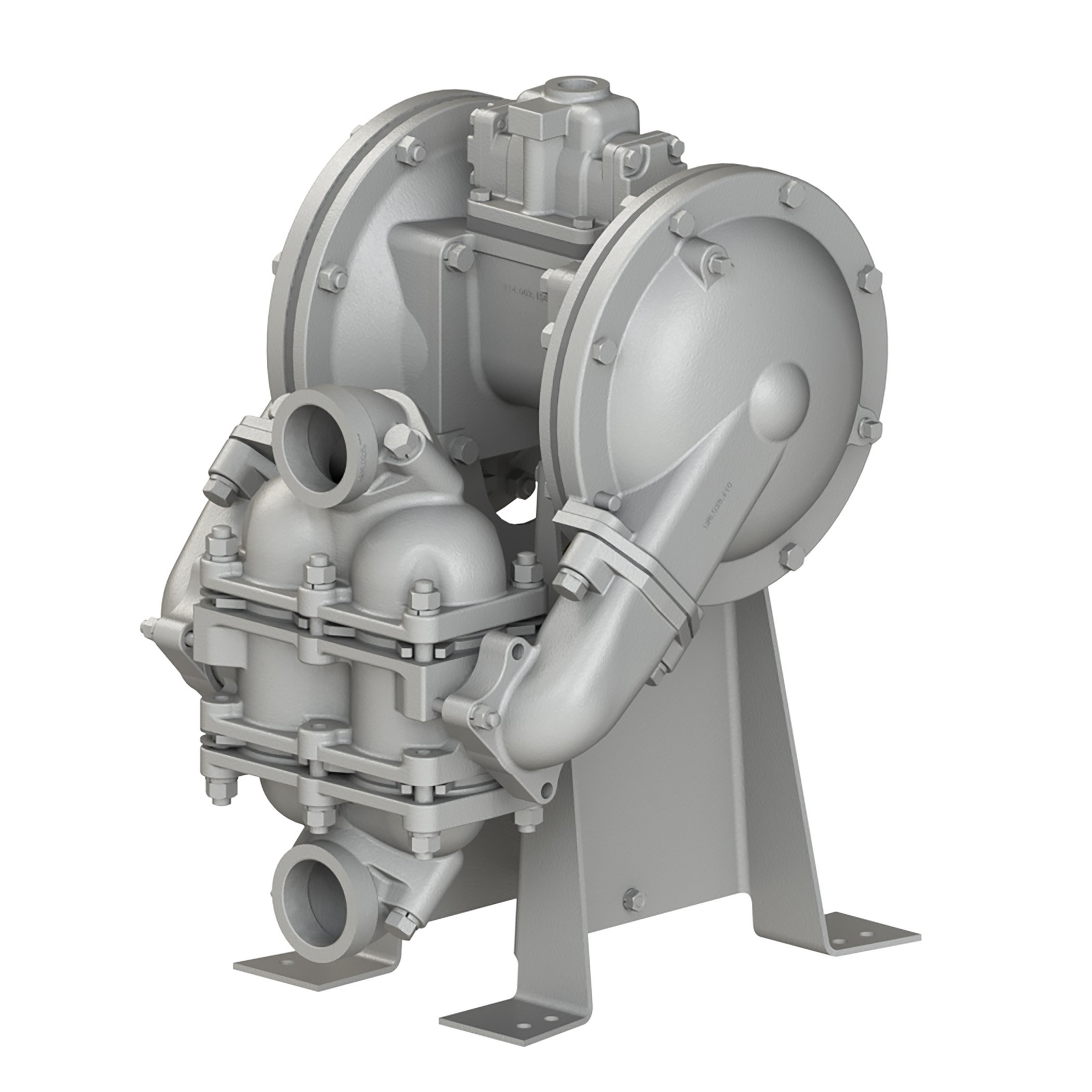

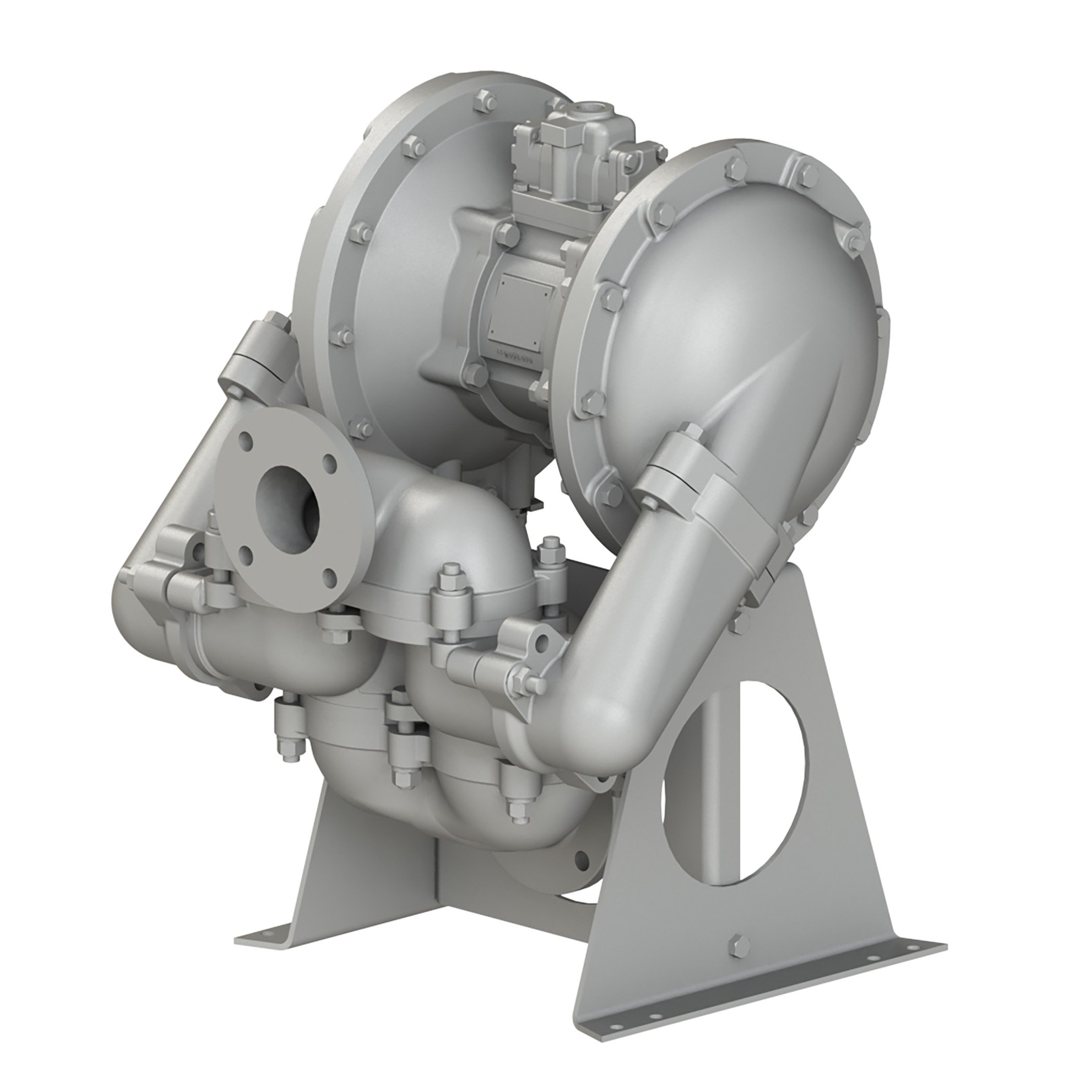

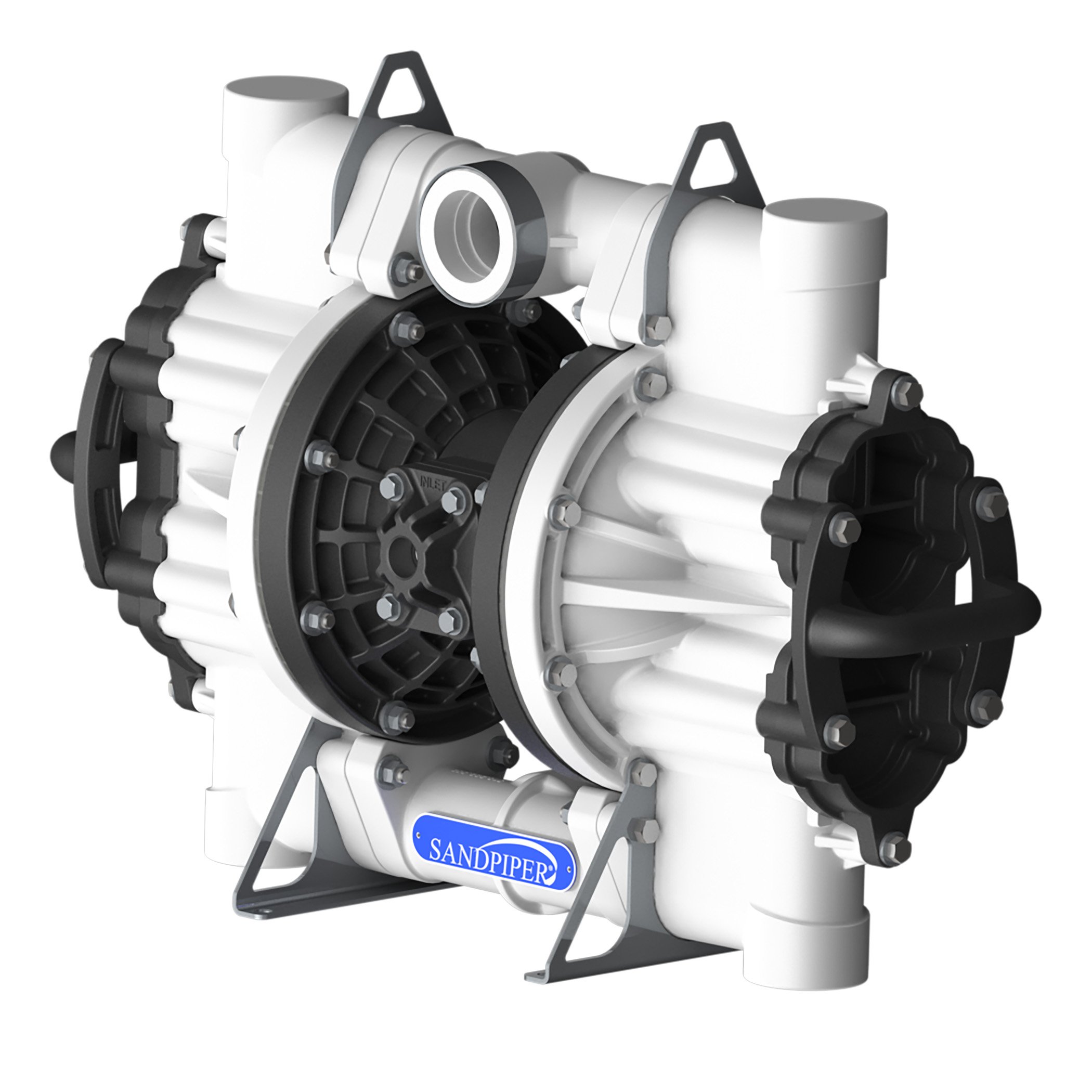

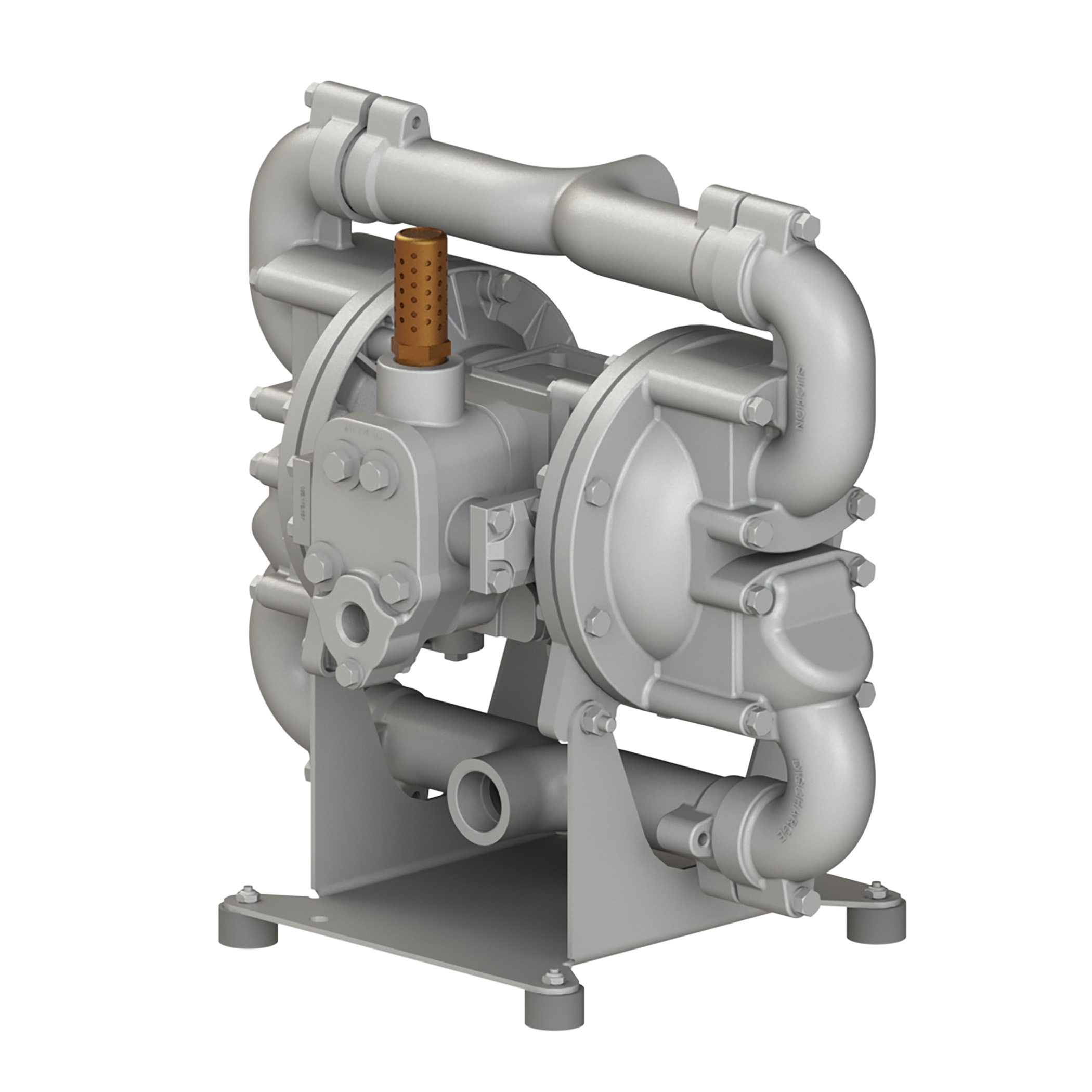

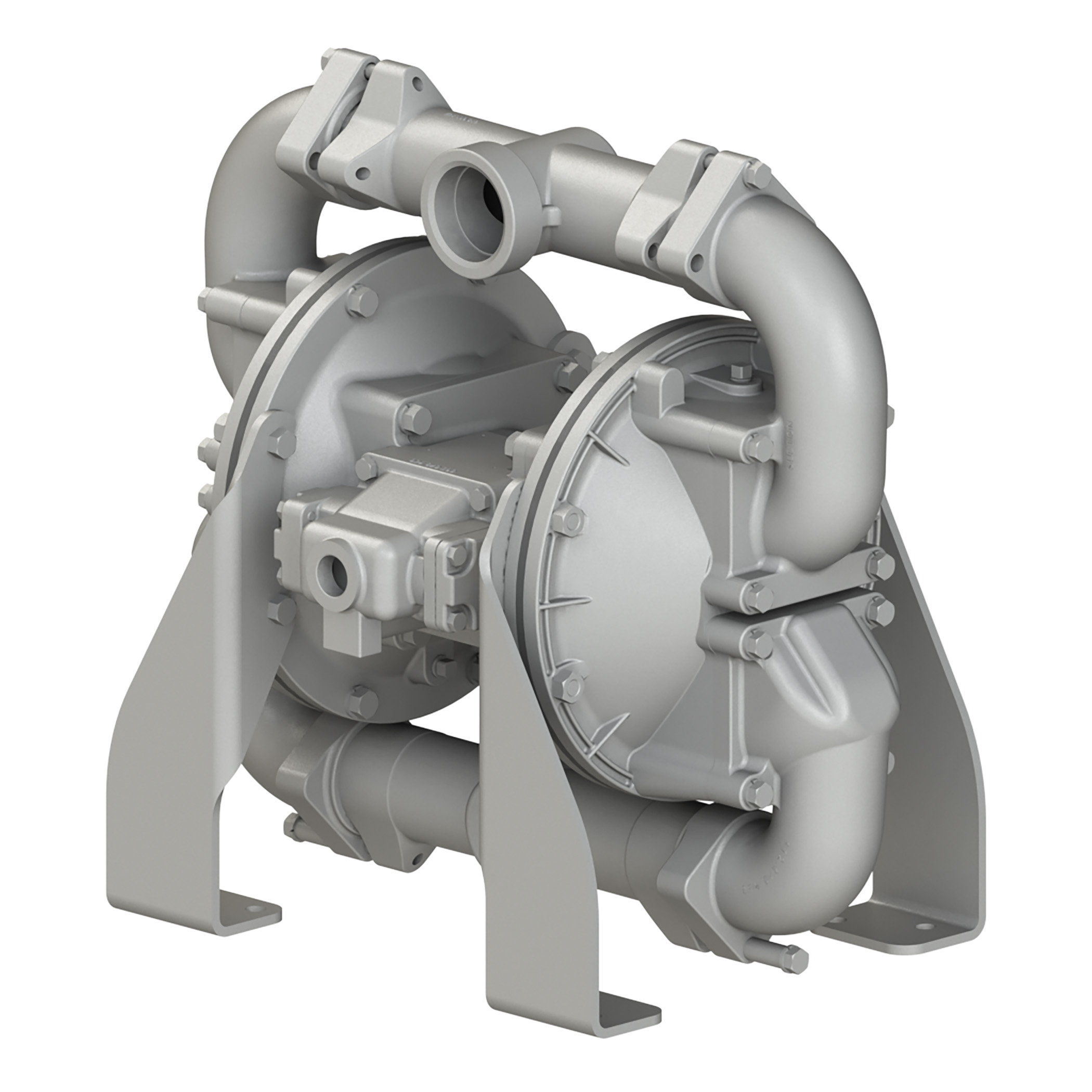

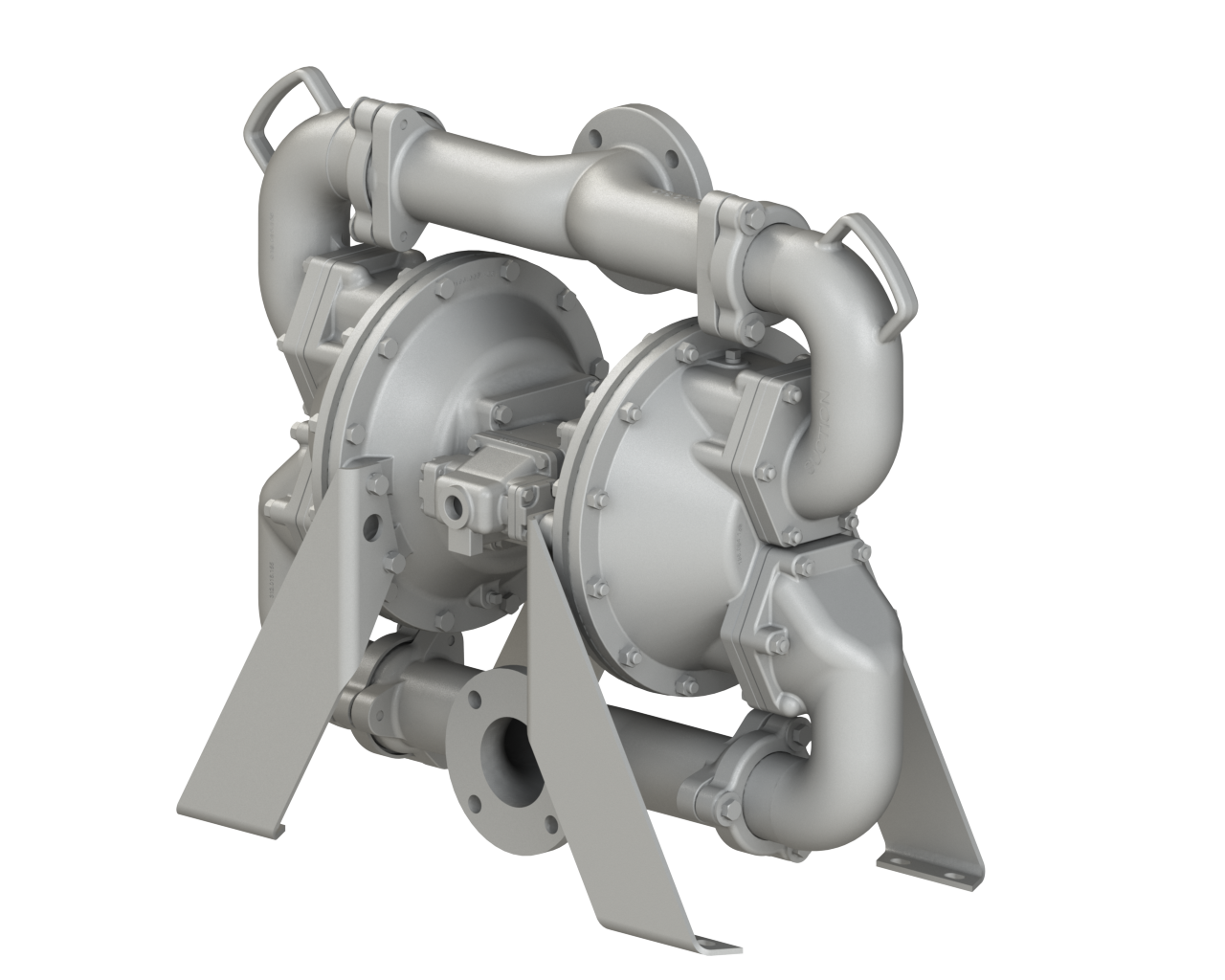

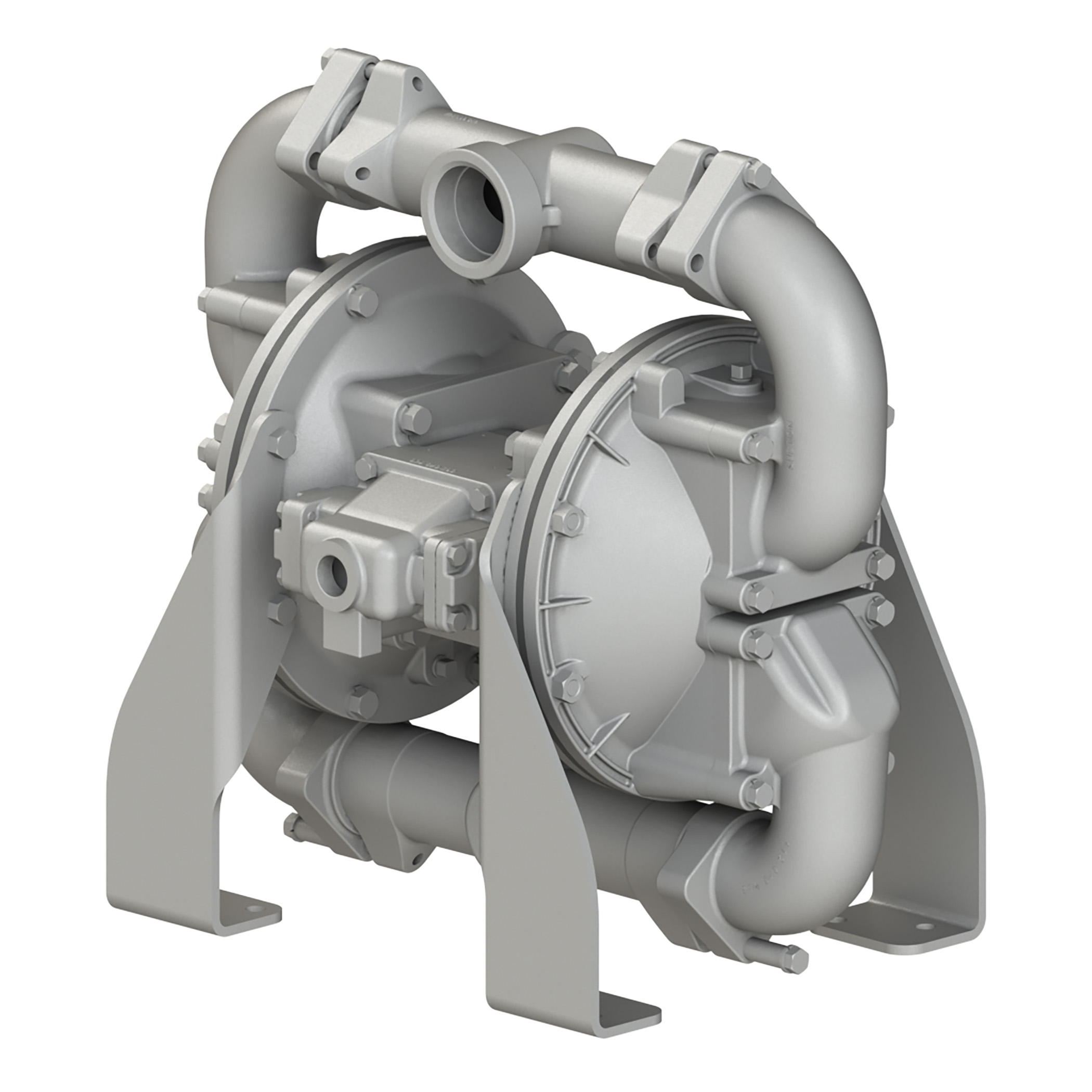

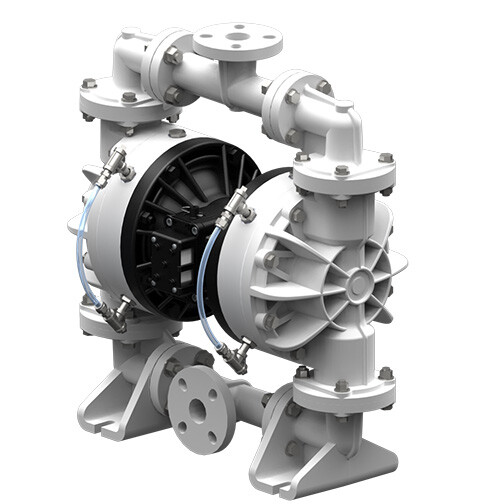

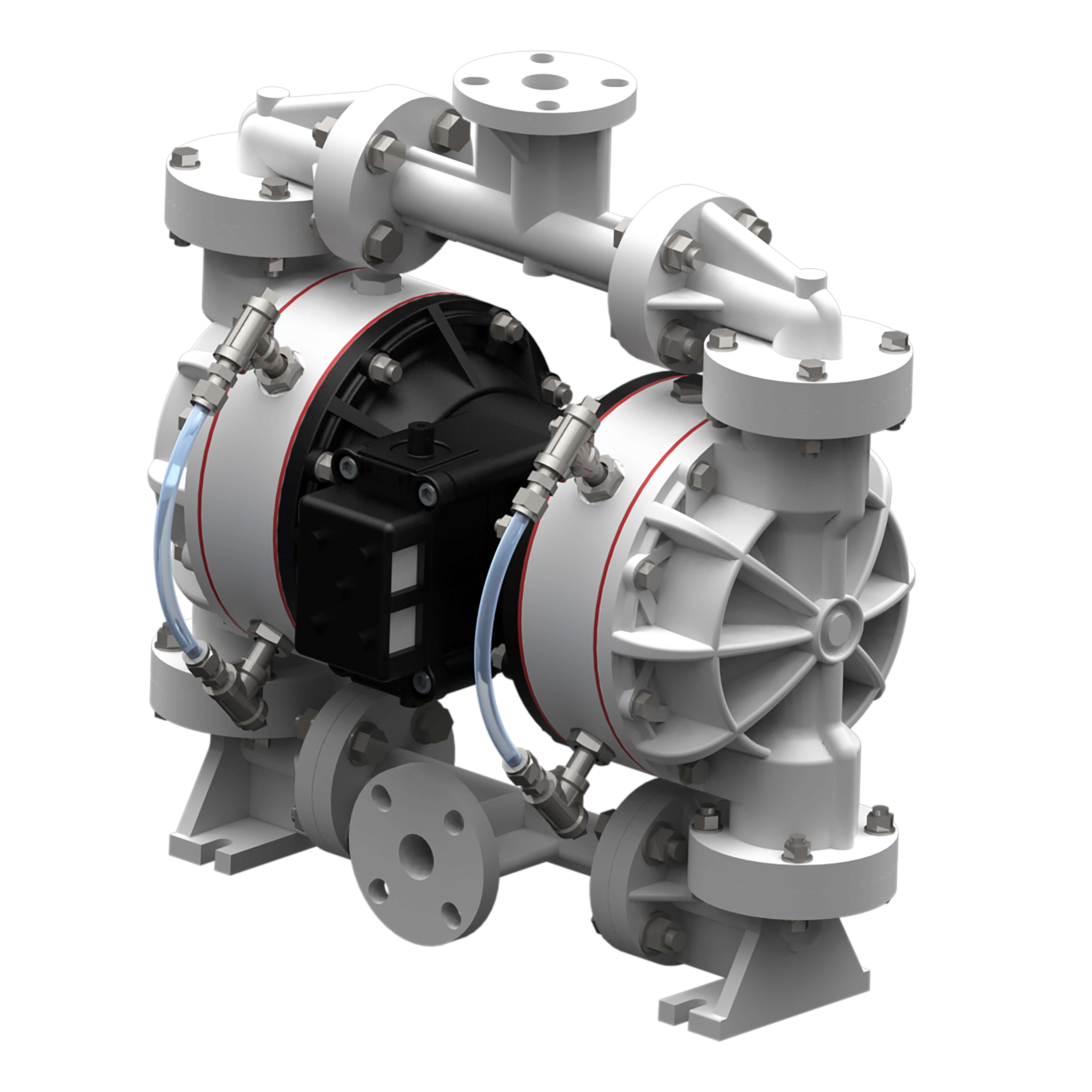

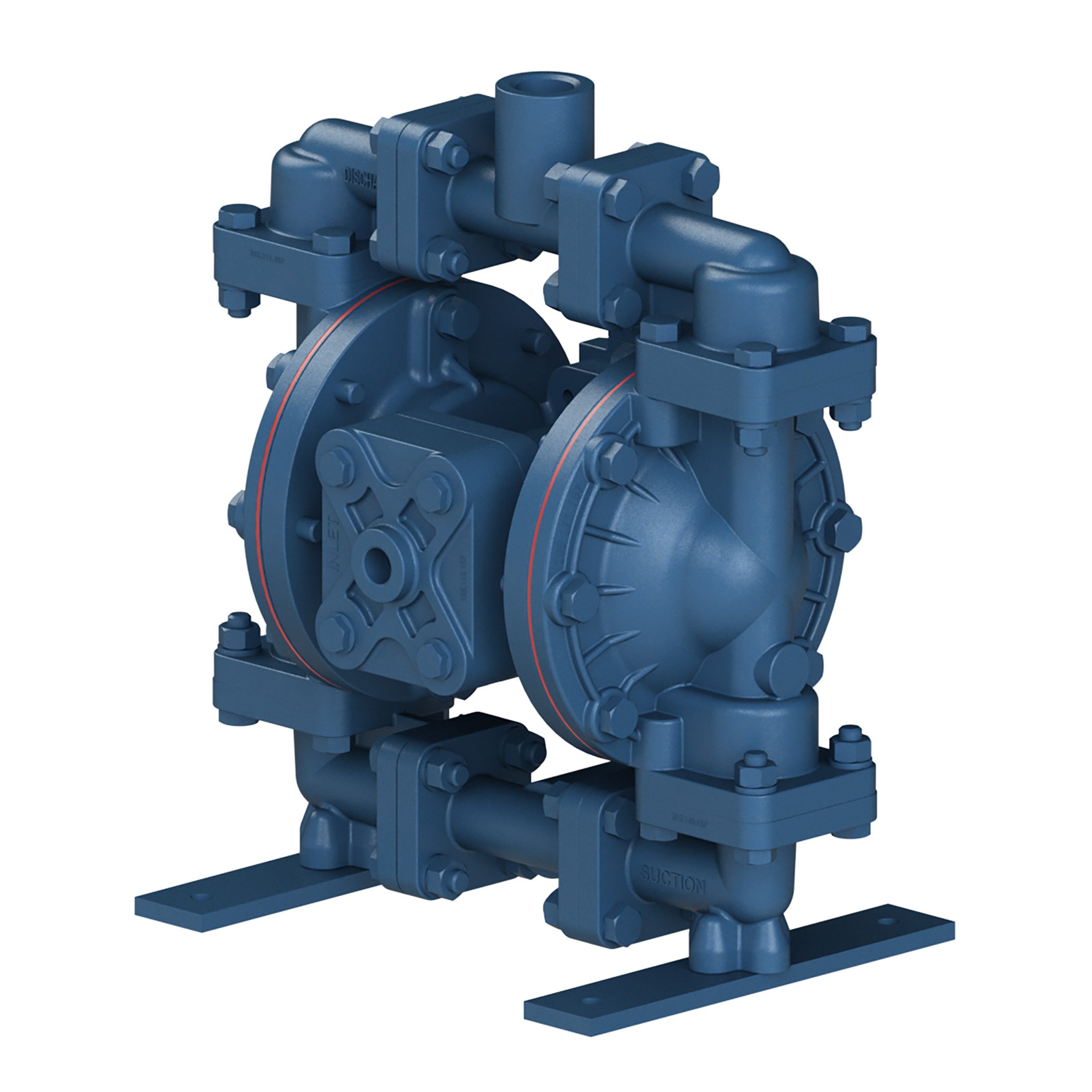

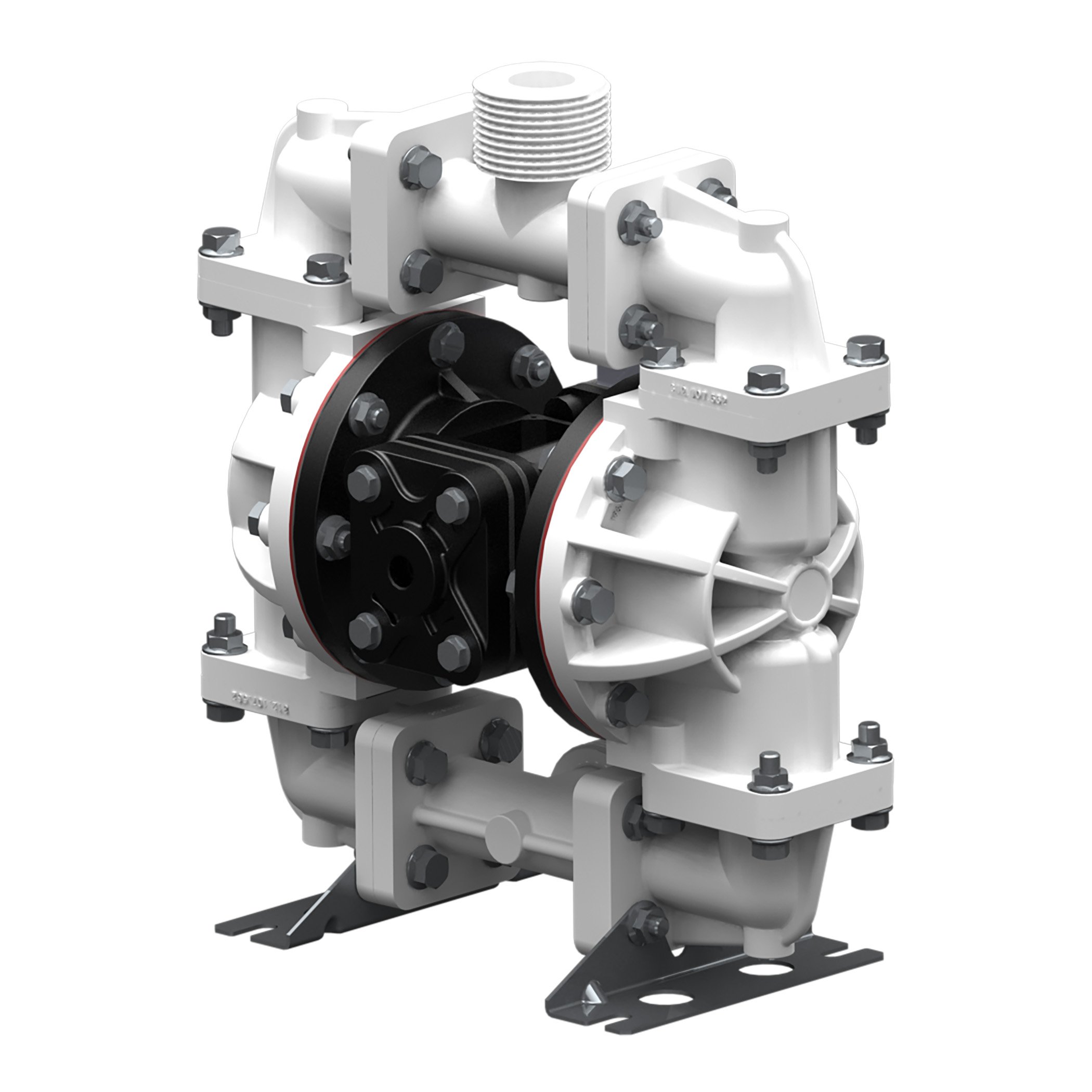

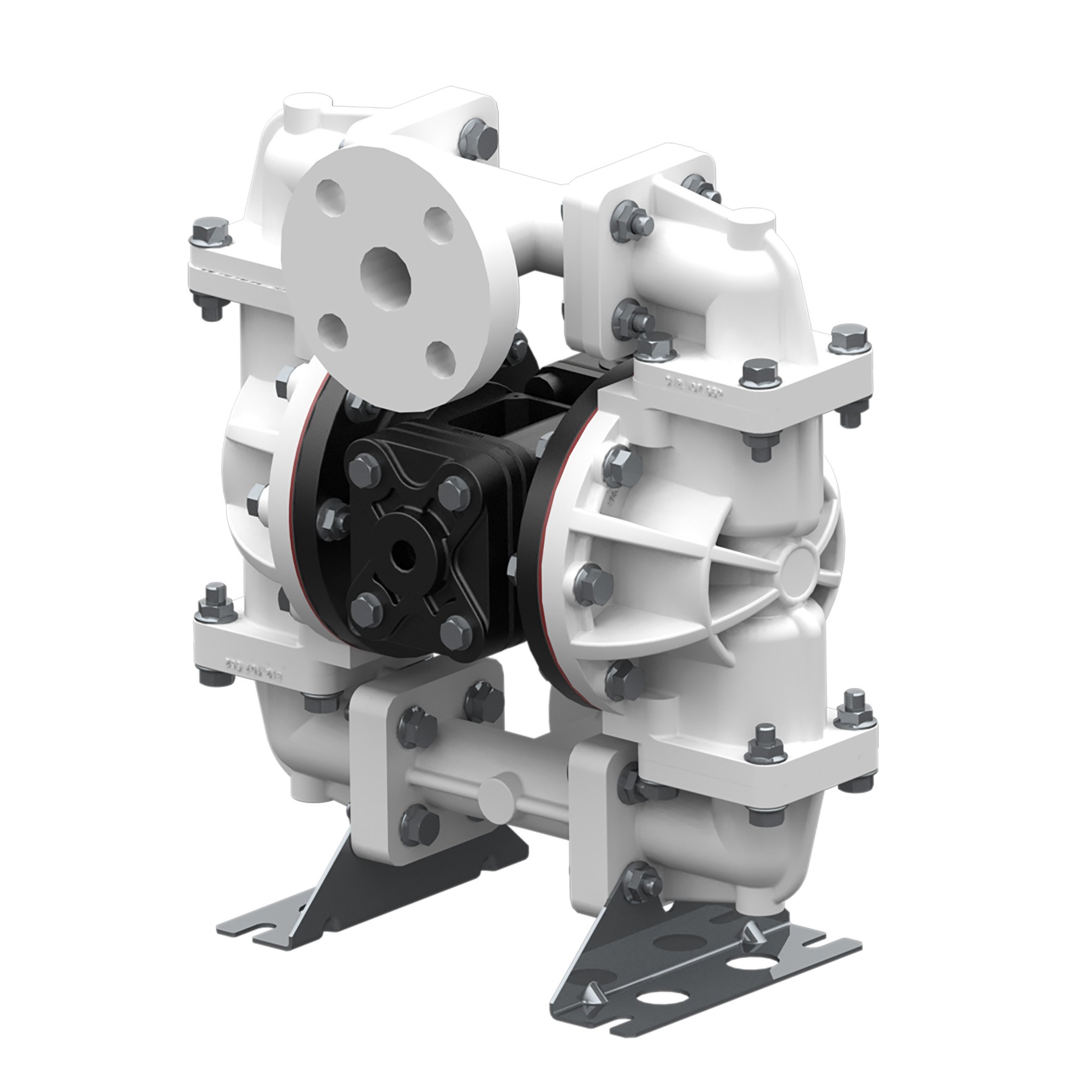

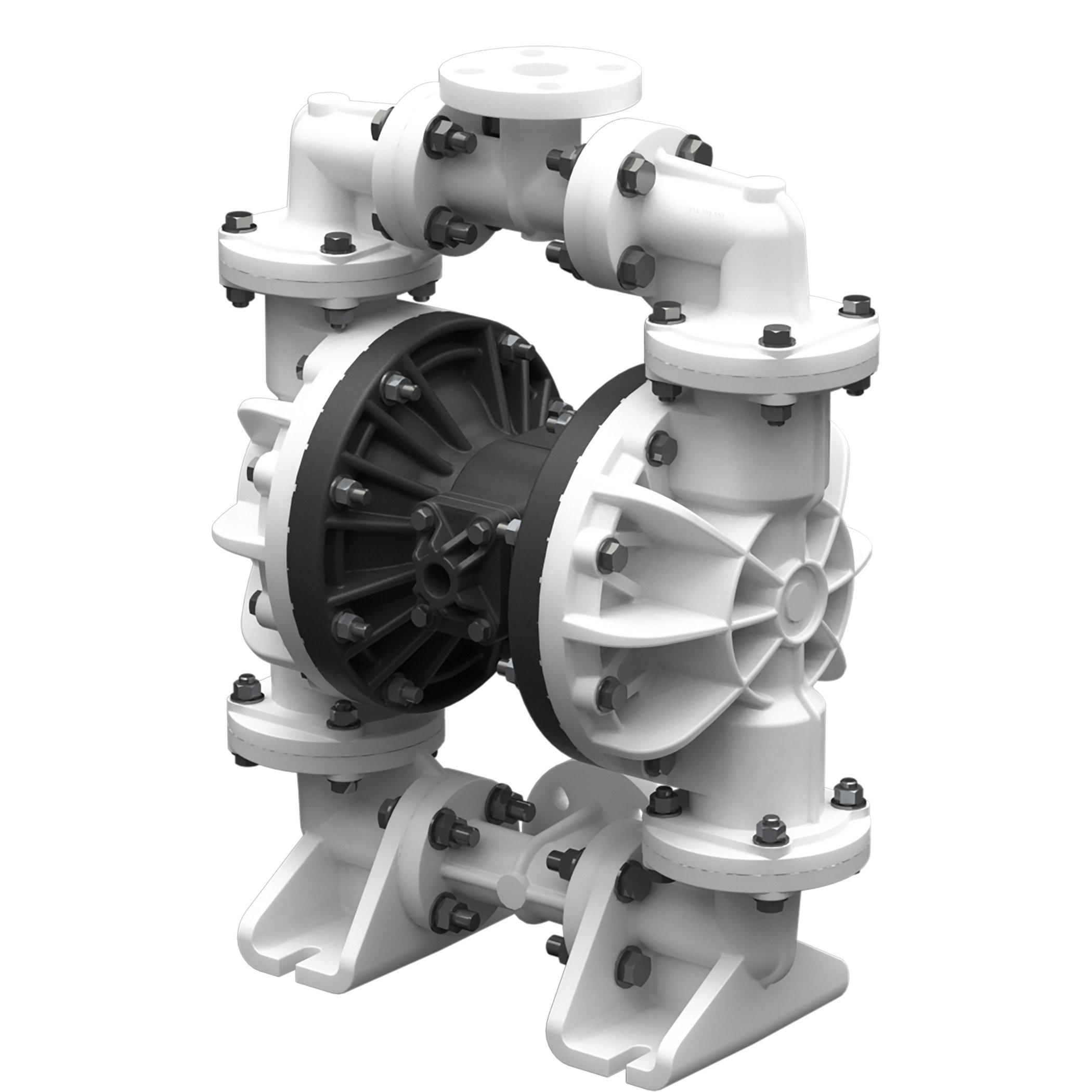

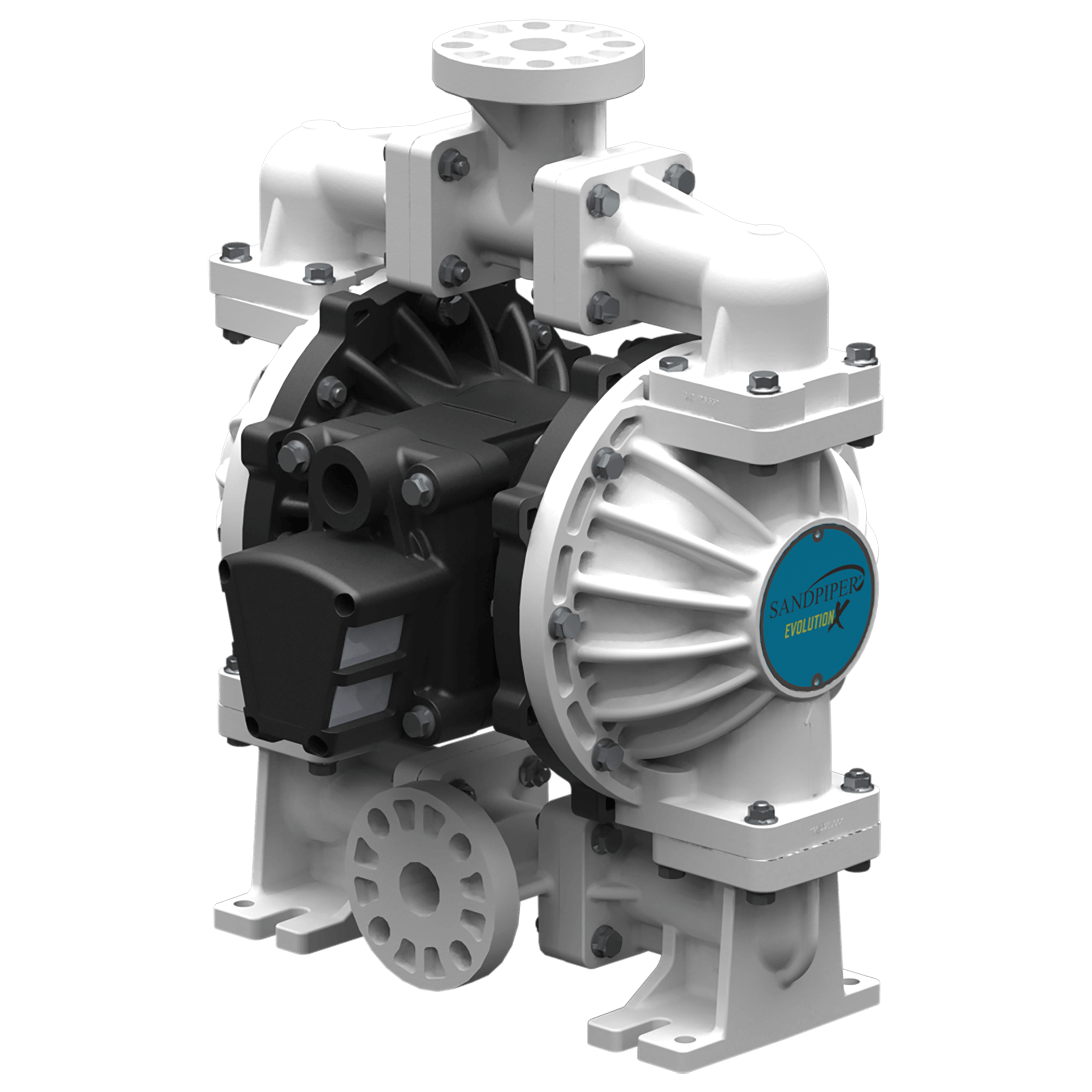

The Next Generation of AODD Pumps

EvolutionX is built for faster maintenance, improved performance and flexible installation across more applications.

Search by Size

Not sure where to start? We recommend starting with pump size. Click below to get started.

Search by Size

Not sure where to start? We recommend starting with pump size. Click below to get started.