A major benefit of air-operated double-diaphragm (AODD) pumps for manufacturing paint and other coatings is their ability to handle a variety of fluids, including oil, ethanol and even hazardous chemicals such as ammonia or biocides. In addition to these harsh environments, AODDs are excellent at gentle, low-shear pumping which does not damage precious materials. AODD pumps in the coatings industry can also pump the clumps that form during milling and filtration when resins, solids and pigments come together to make paint and other coatings.

The Right Pump Reduces Operating Costs

Selecting the right pump guarantees an efficient production process that spans unloading raw materials, tank storage, transferring, milling, filtration, straining and filling machines. A pump’s flow rate, resistance to abrasive materials and the ability to adjust to changing back pressures from the straining operations will ensure a trouble-free production line with minimal unplanned maintenance.

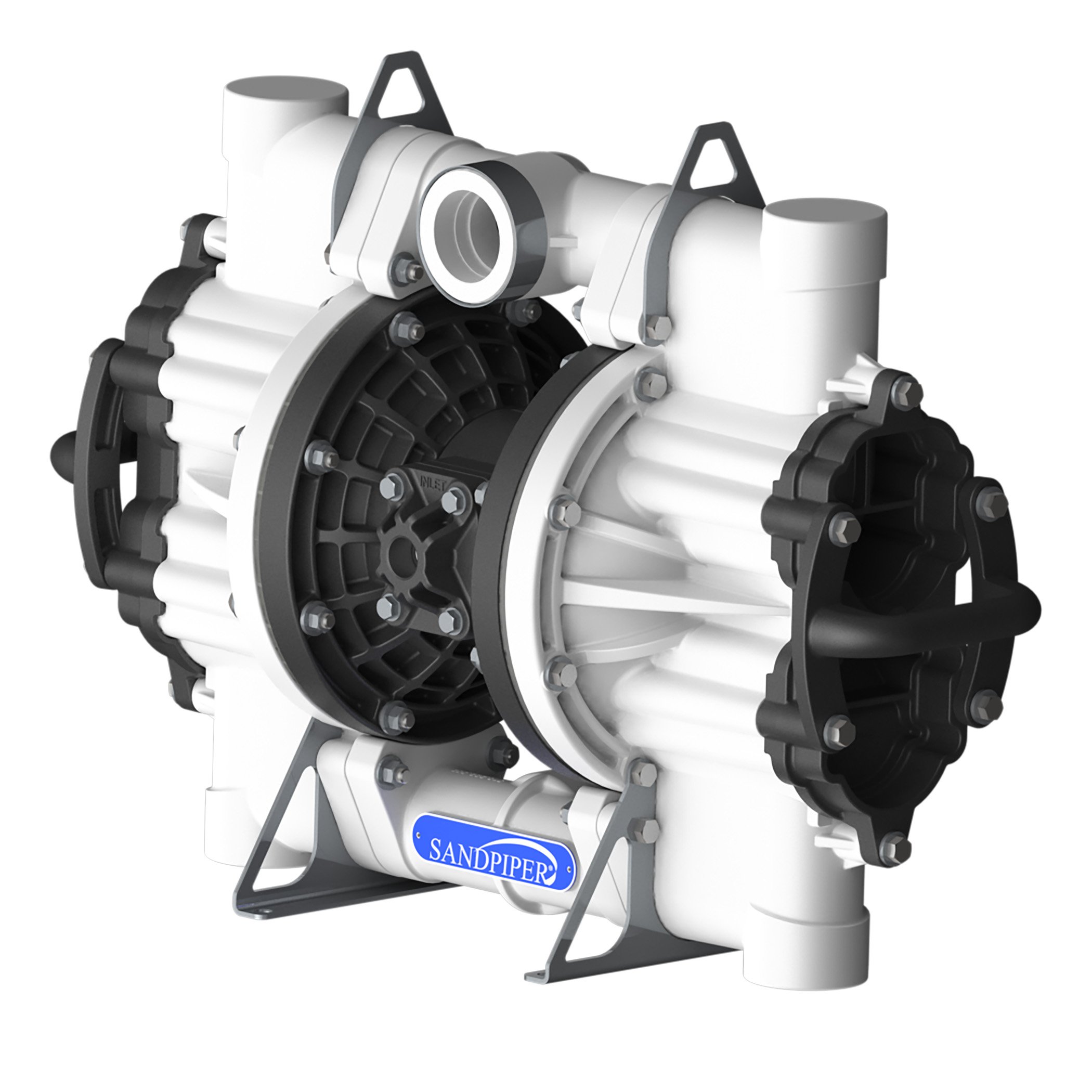

The growing trend of biocide-free paints is changing the manufacturing requirements across the paint industry as hazardous materials are removed from the process. This trend toward safety requires new and different pumping technologies. SANDPIPER’s broad portfolio of AODD pumps and our deep market knowledge can help you select the perfect pump even with these changing requirements:

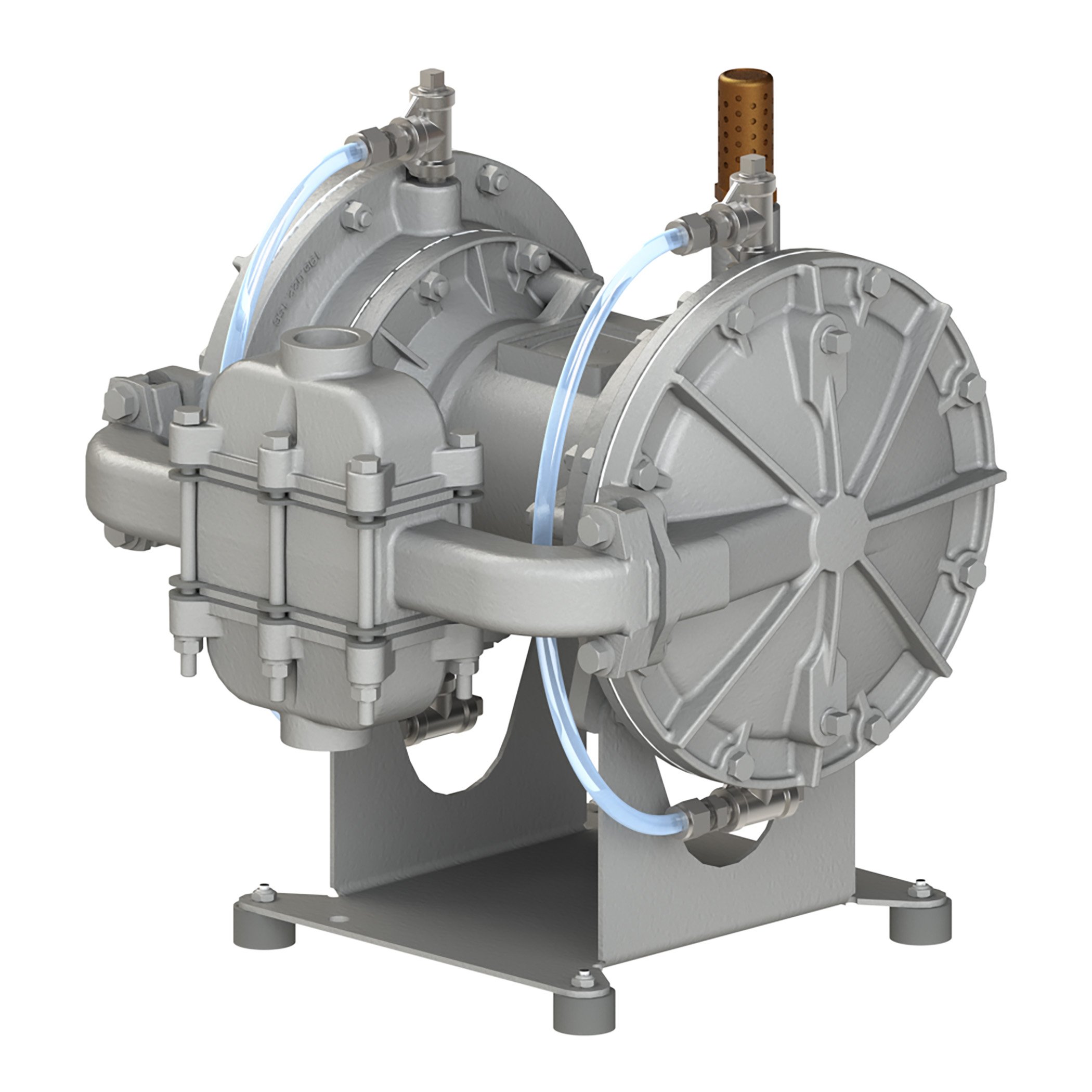

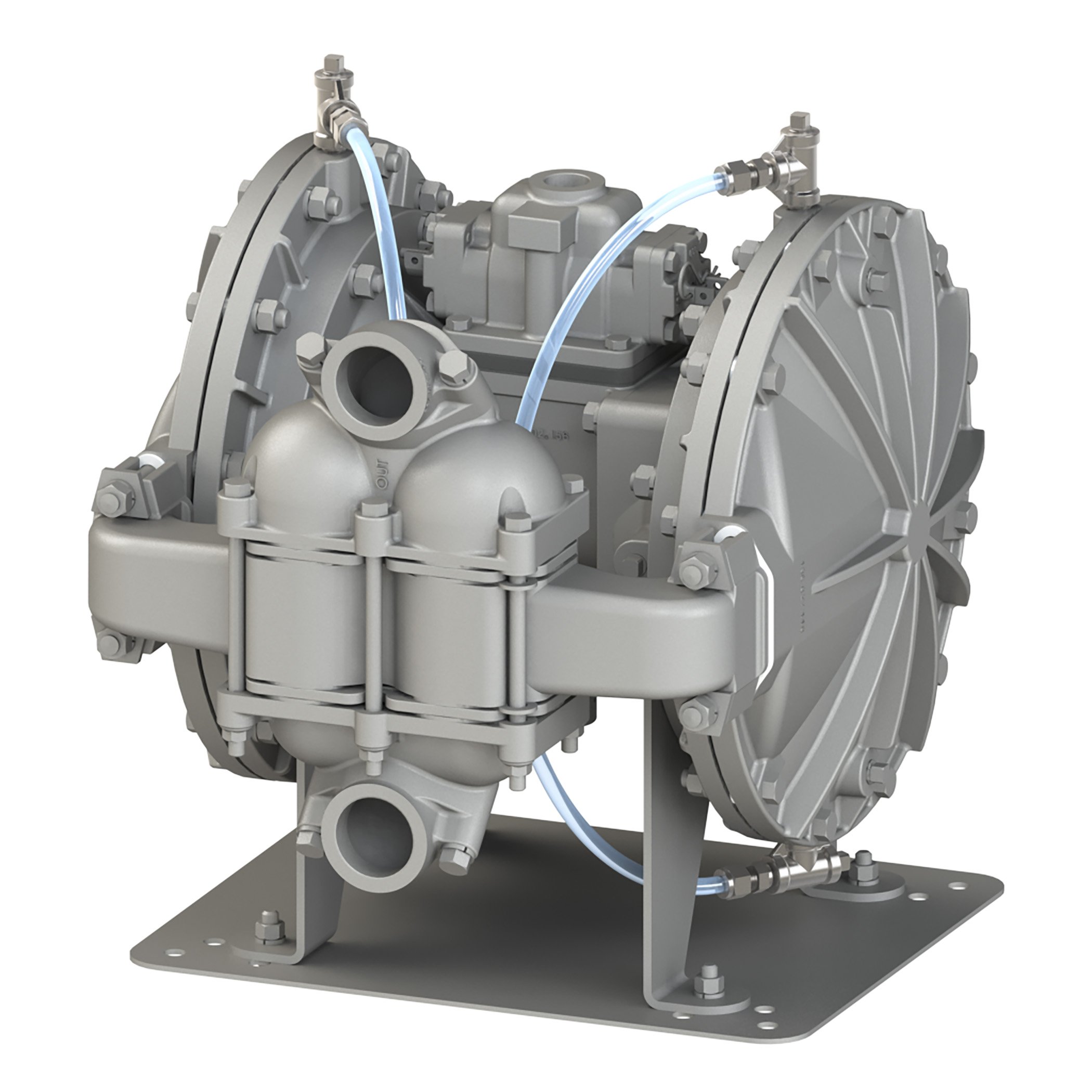

- Containment Duty: The secondary containment chamber prevents and detect leaks, eliminating the hazardous materials exposure risk to employees and the environment.

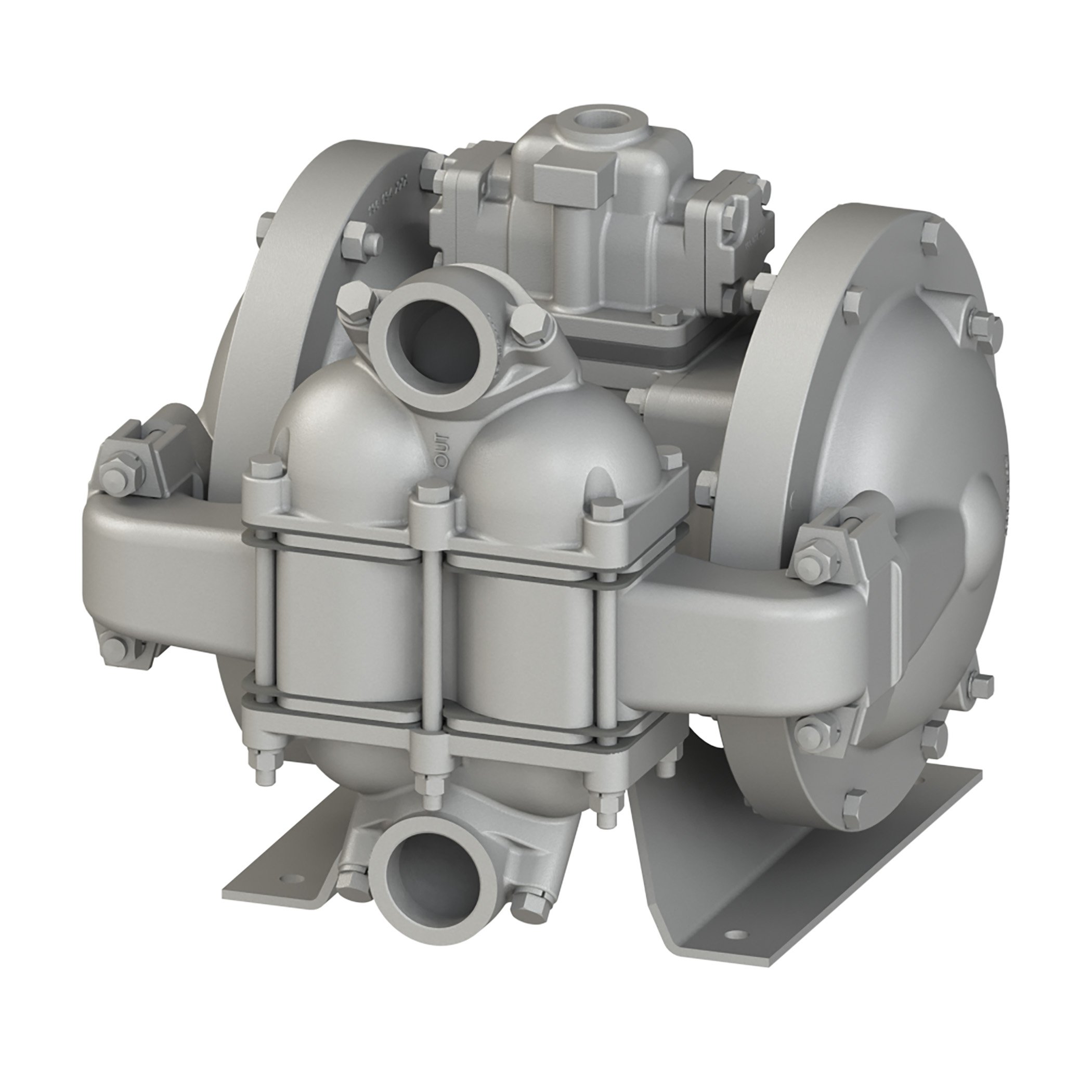

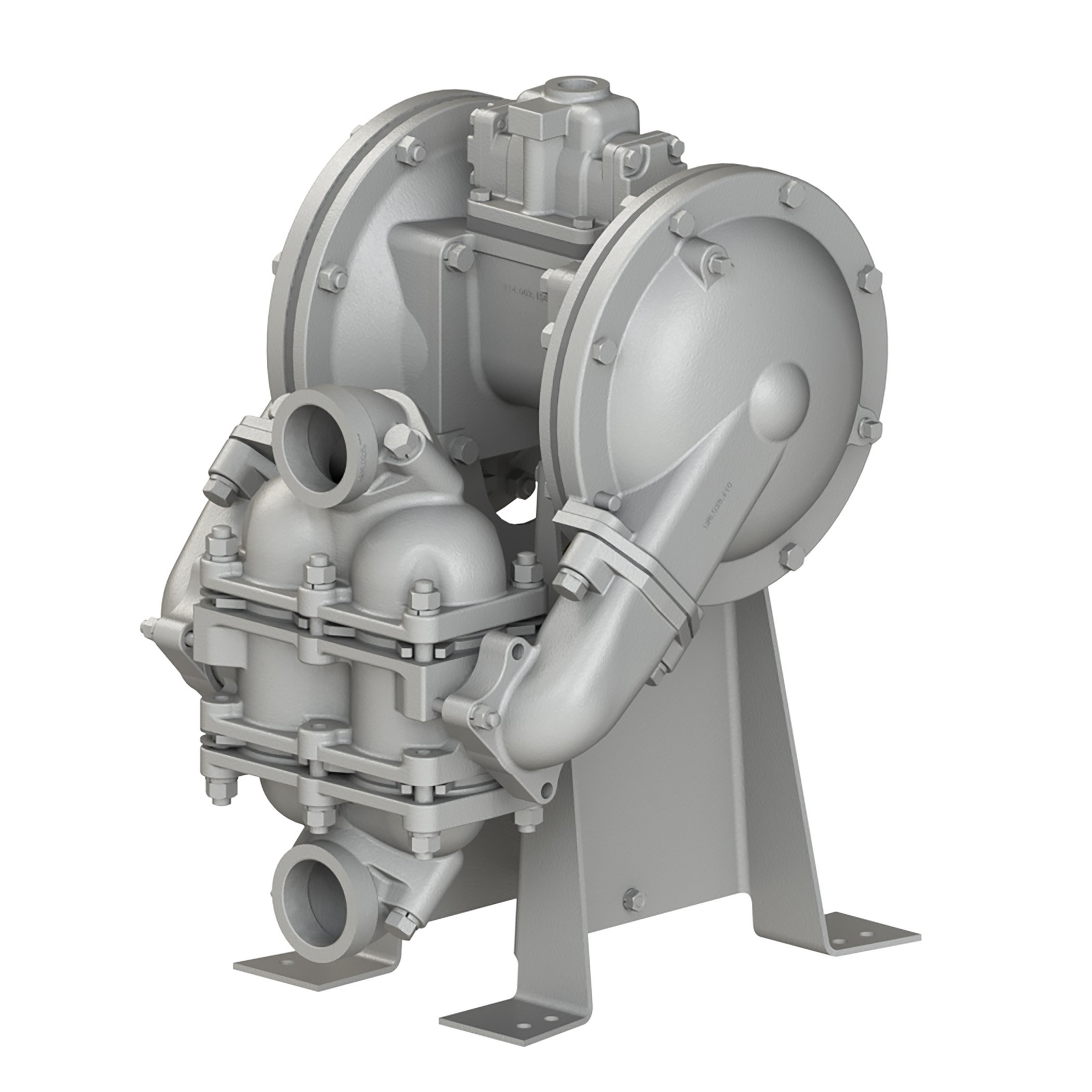

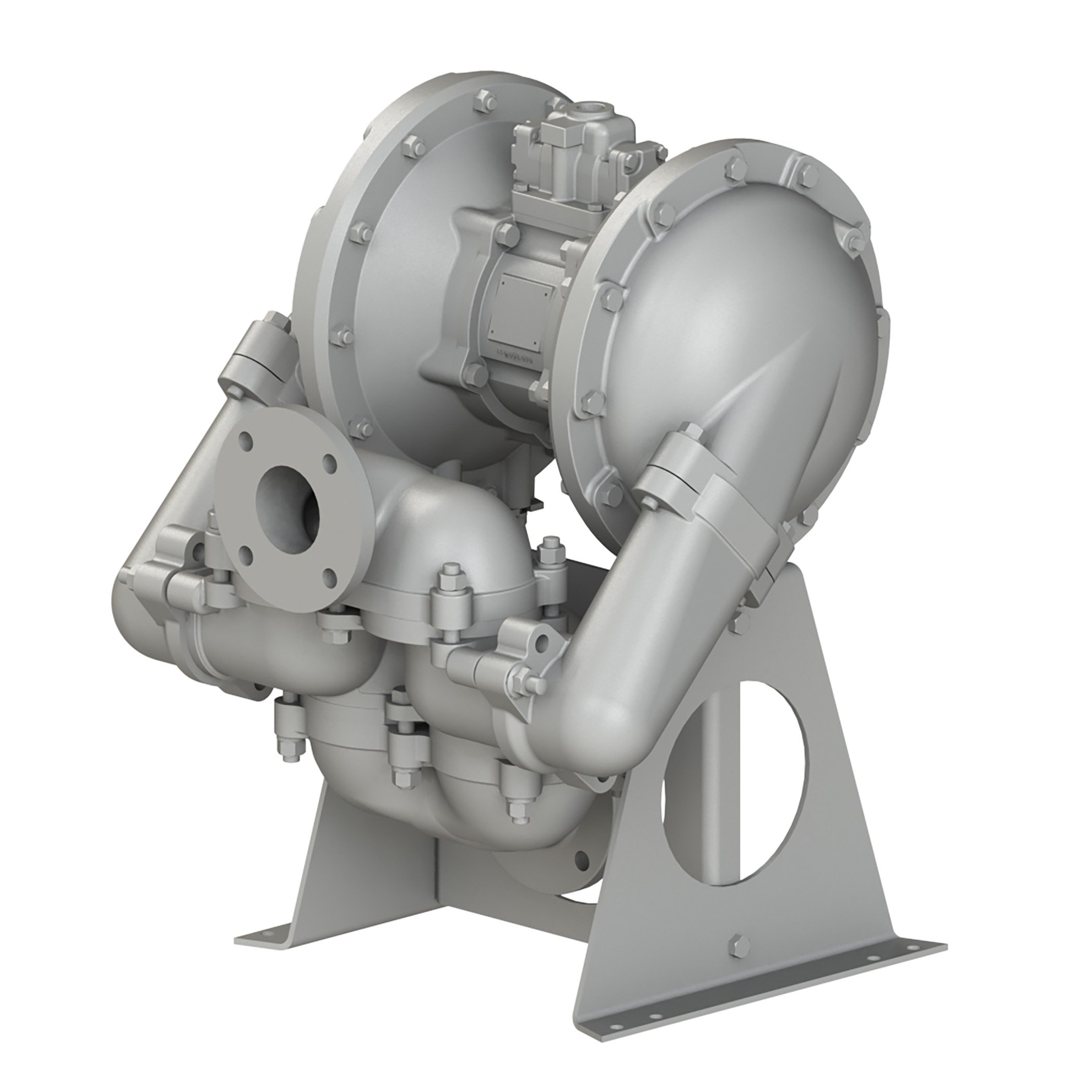

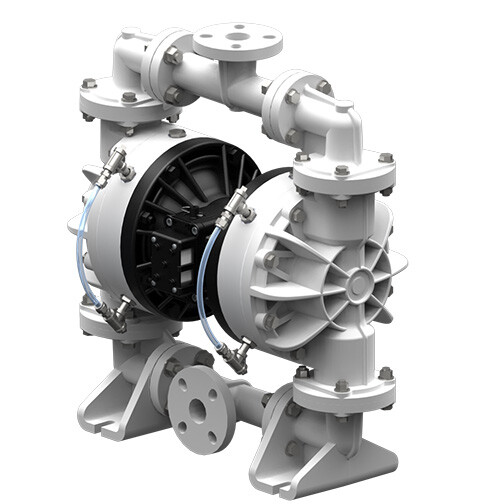

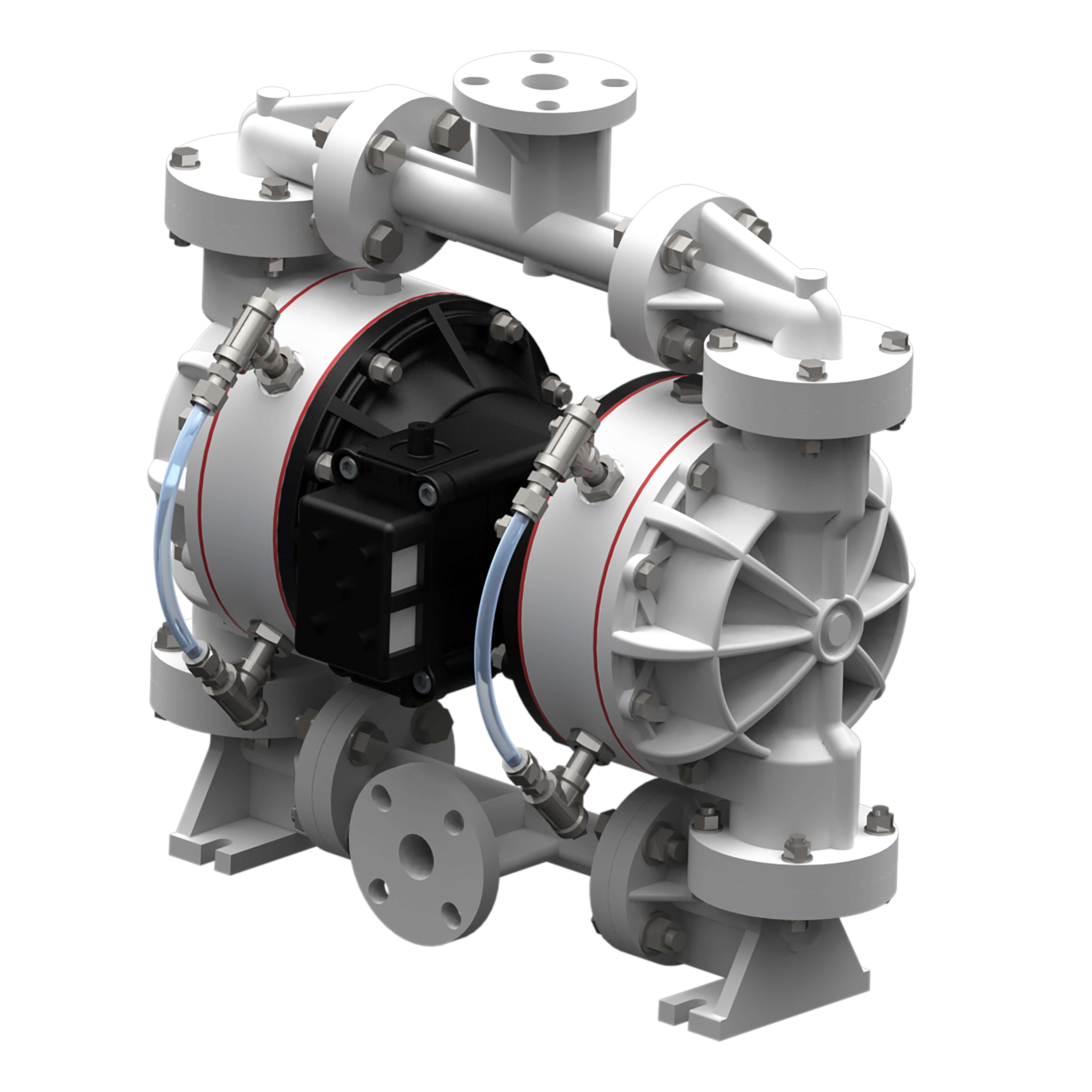

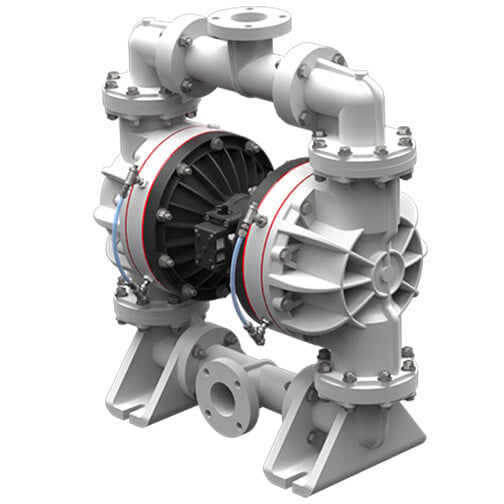

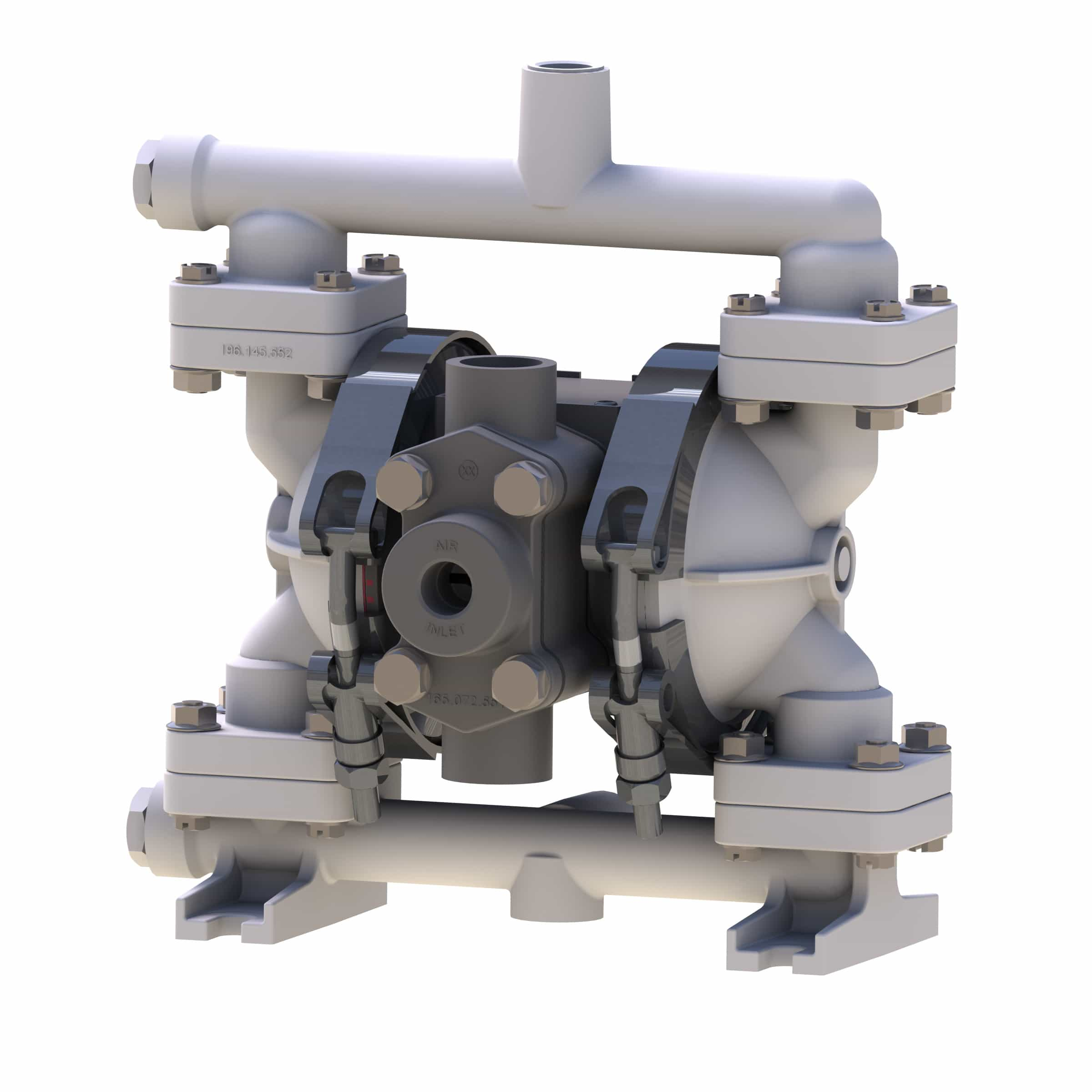

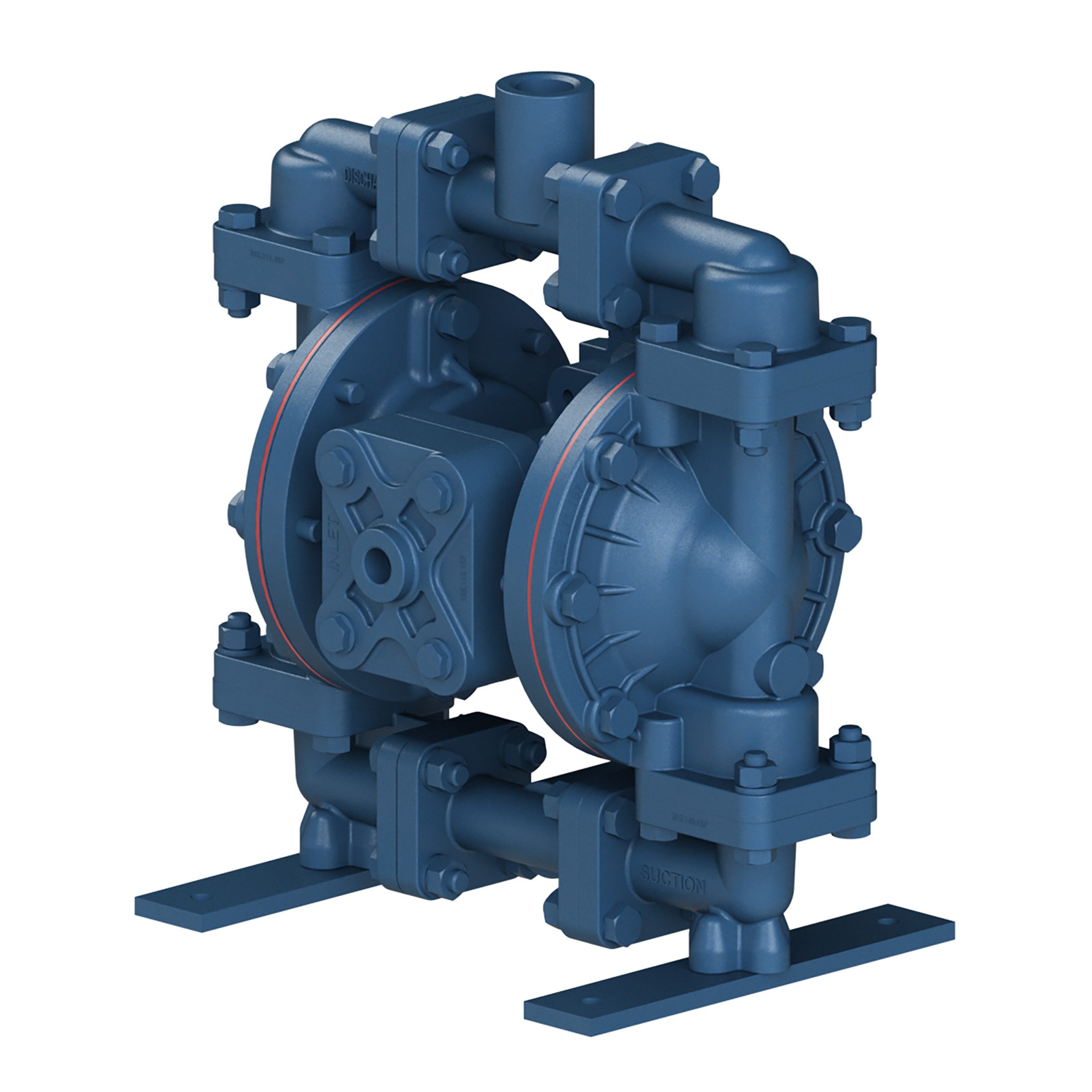

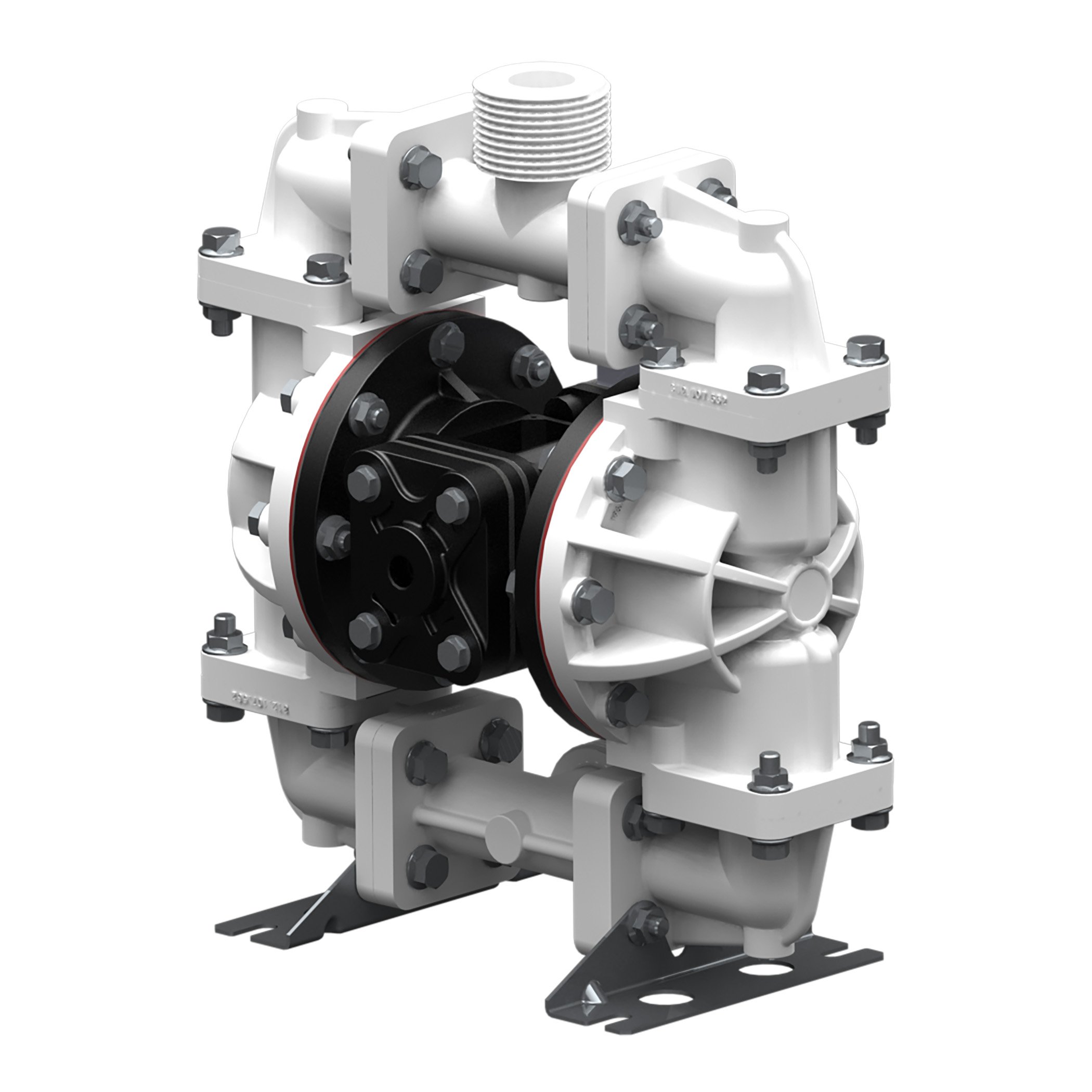

- Heavy-Duty: Flap valve and ball valve pumps designed with bolted, thick wall construction provides class-leading performance when pumping abrasive, viscous and solid-laden fluids, slurries and resins.

- Sanitary & Hygienic: Stainless-steel designs used for applications where avoiding batch contamination and the ability to drain and clean are critical. These pumps are compliant with federal hygienic standards and good manufacturing practice (GMP) standards.

COMMONLY USED AODD PAINT, INKS AND COATINGS APPLICATIONS

- Loading/Unloading/Transfer: across all steps of the manufacturing process to move raw or partially processed materials to next step production

- Premixing: wide range from thin to viscous fluids, resins, oils, solvents, plasticizers, surfactants, glues and liquid pigments

- Grinding and milling: processing pigments, colorants and inks to remove clumps and create consistent paste material for batching and dispersion

- Batching/mixing/dispersion: pigment paste combined with resins and batch additives using gentle, low shear pumping to prevent damage as creates a flowable material

- Straining and filtration: used to adjust the viscosity, tint strength, color, gloss and overall appearance before the batch is considered complete

- Filling: outbound containers filled with finished products that range from thin to abrasive and viscous fluids

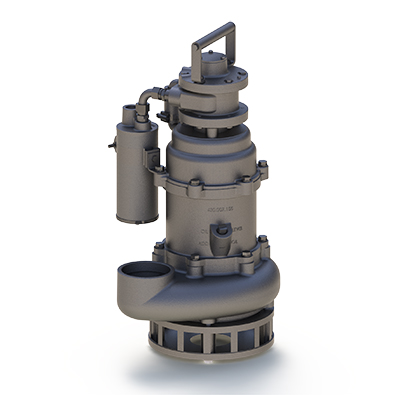

- Wastewater and sump: facility treatment of all liquids generated on-site in its manufacturing process, including water runoff

- Filter press: remove byproducts and waste from the manufacturing process. Sludge formed from latex and water-based solvents can be captured, recycled and reused

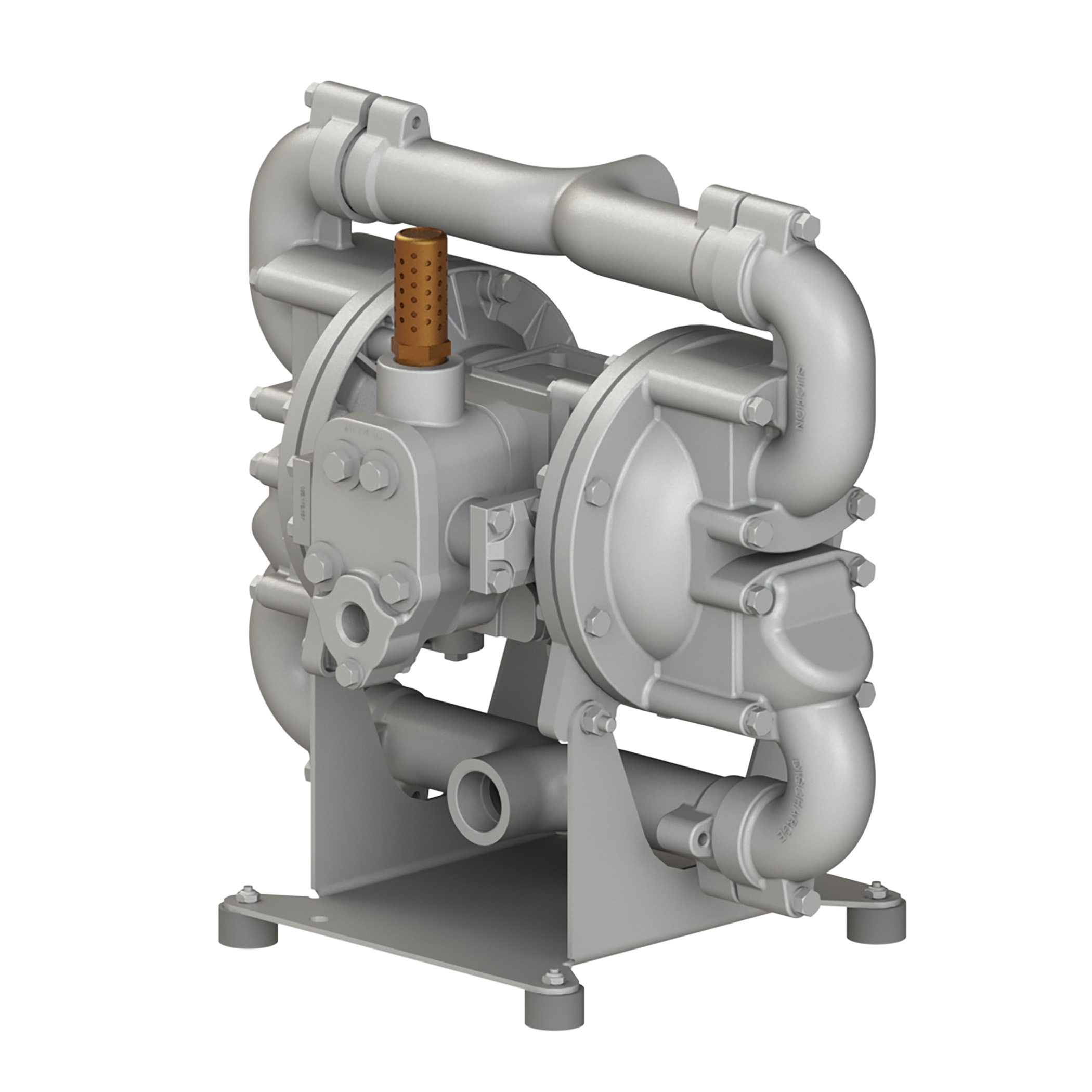

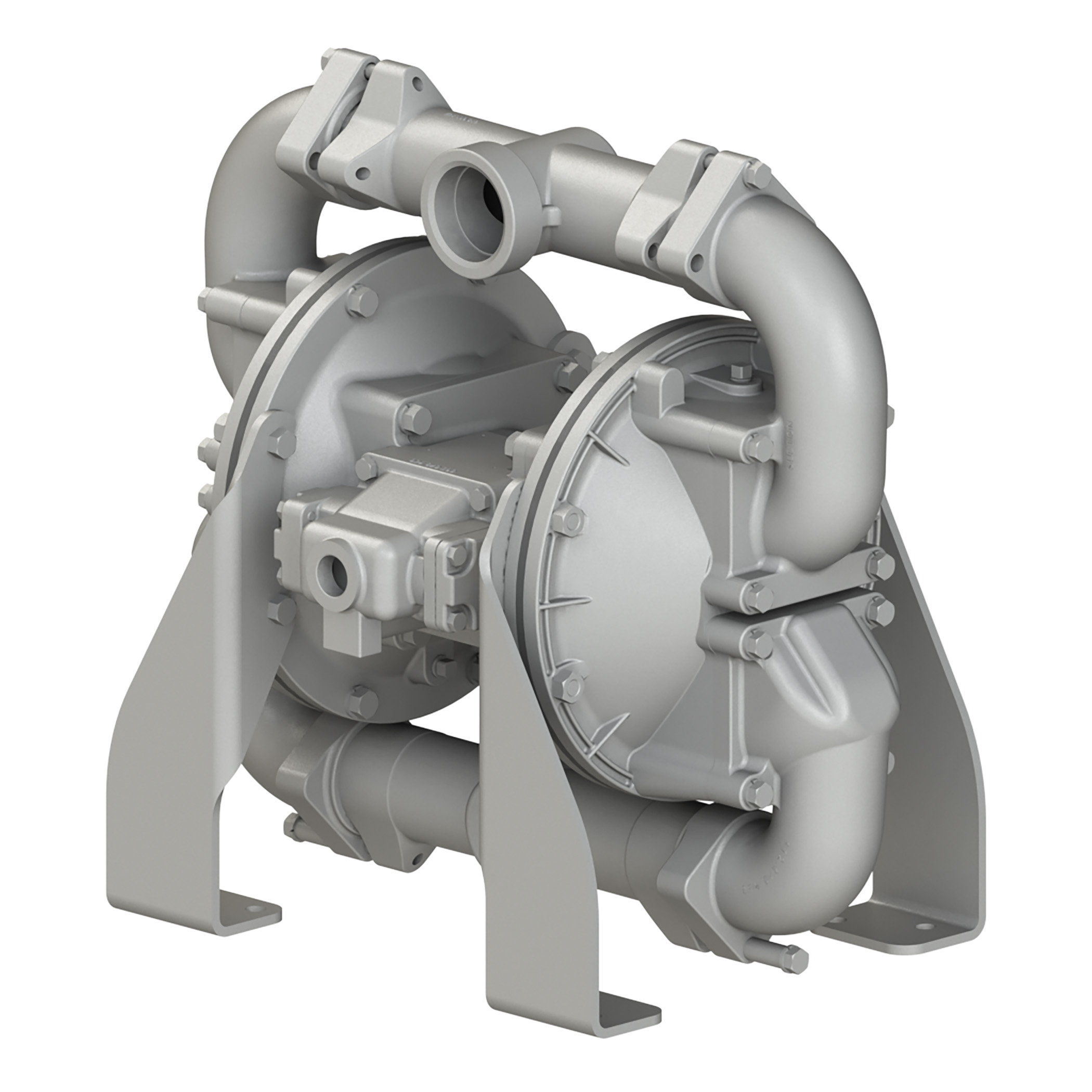

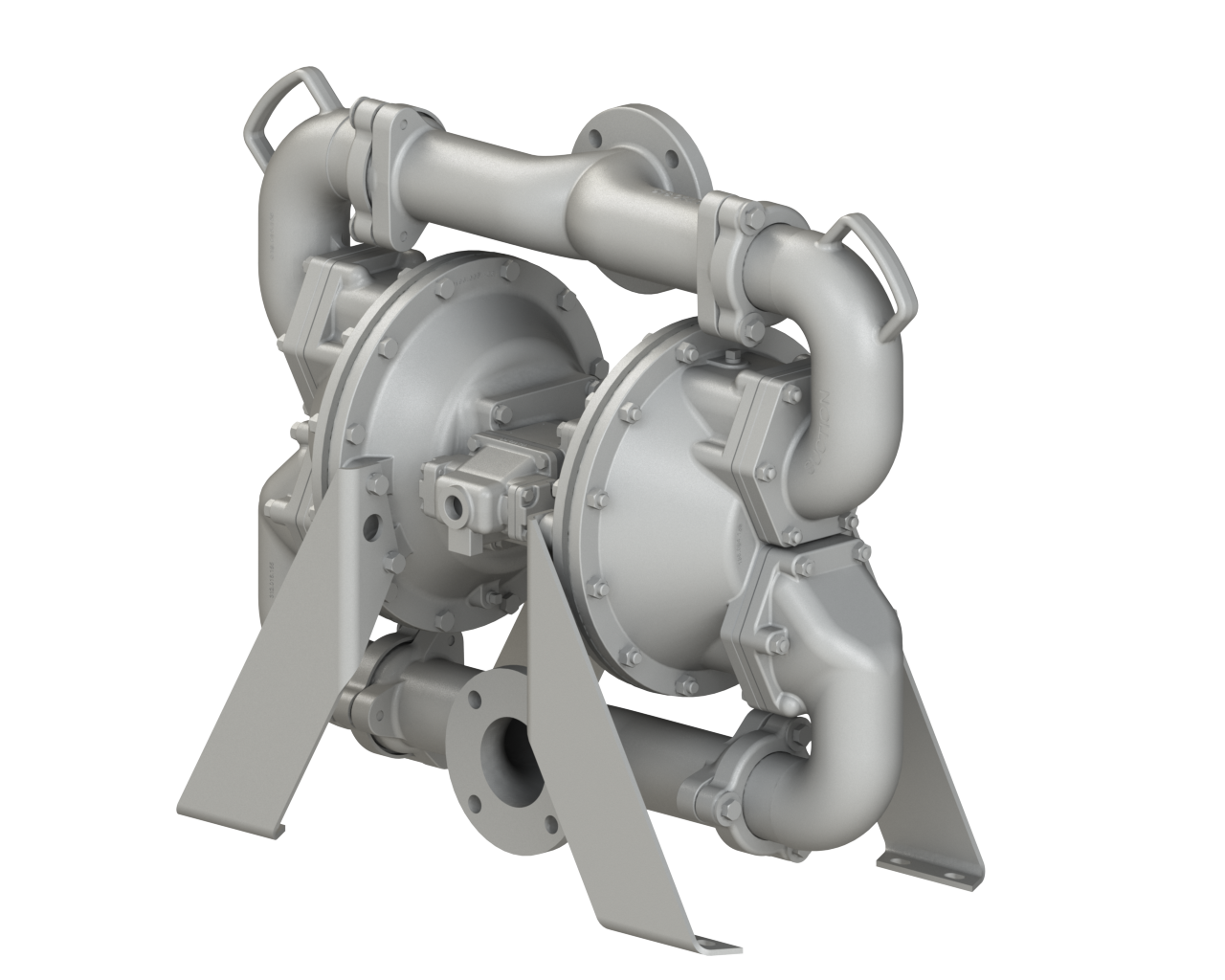

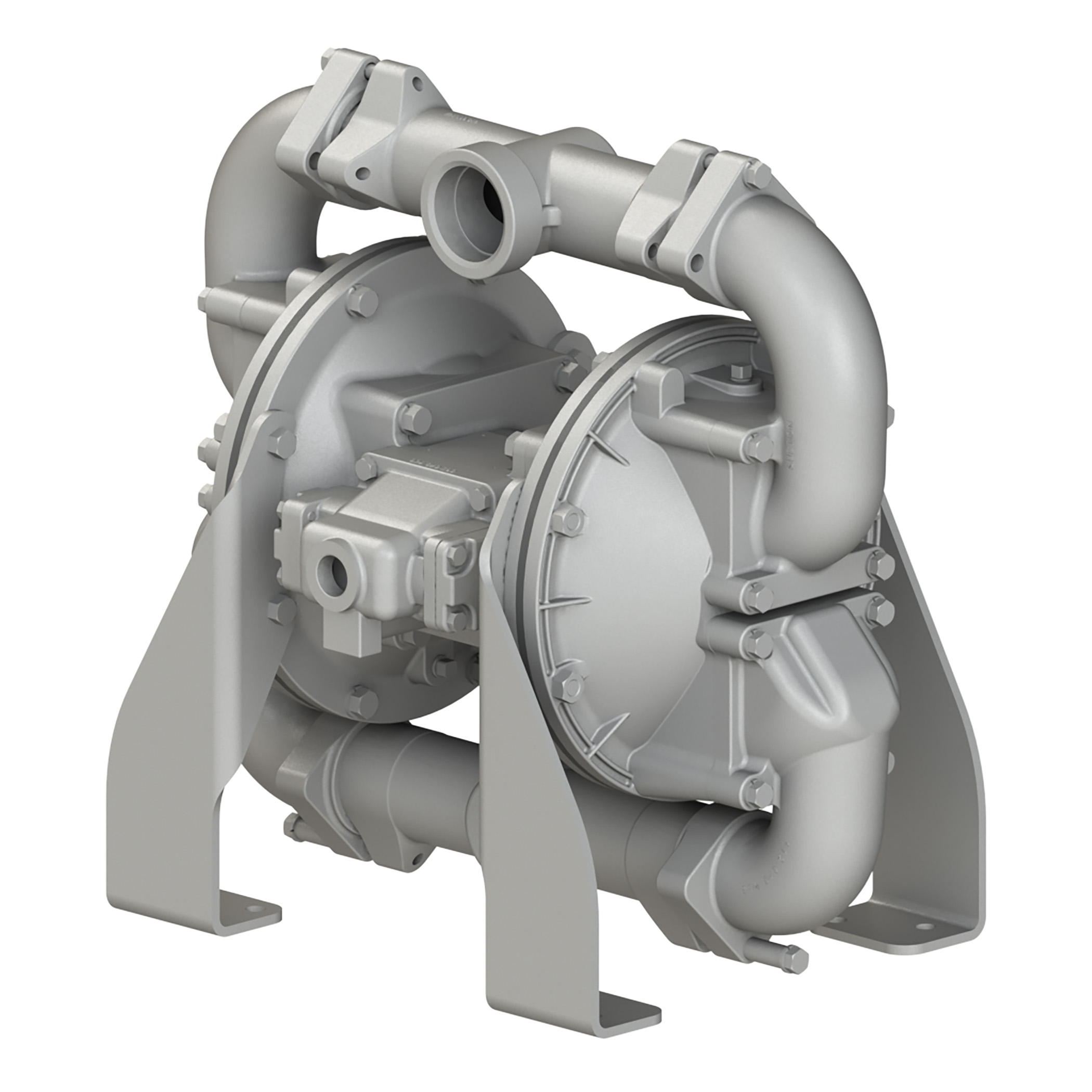

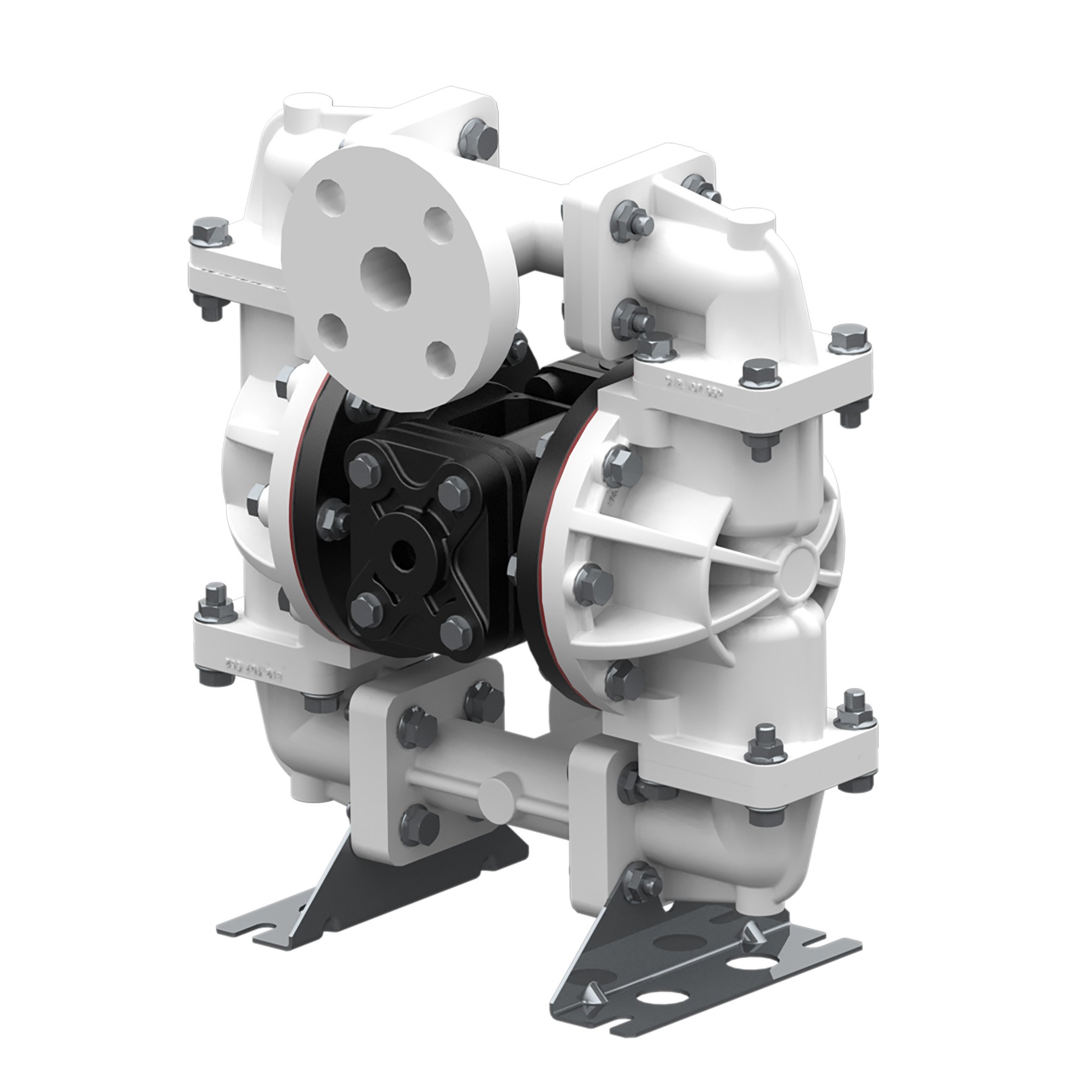

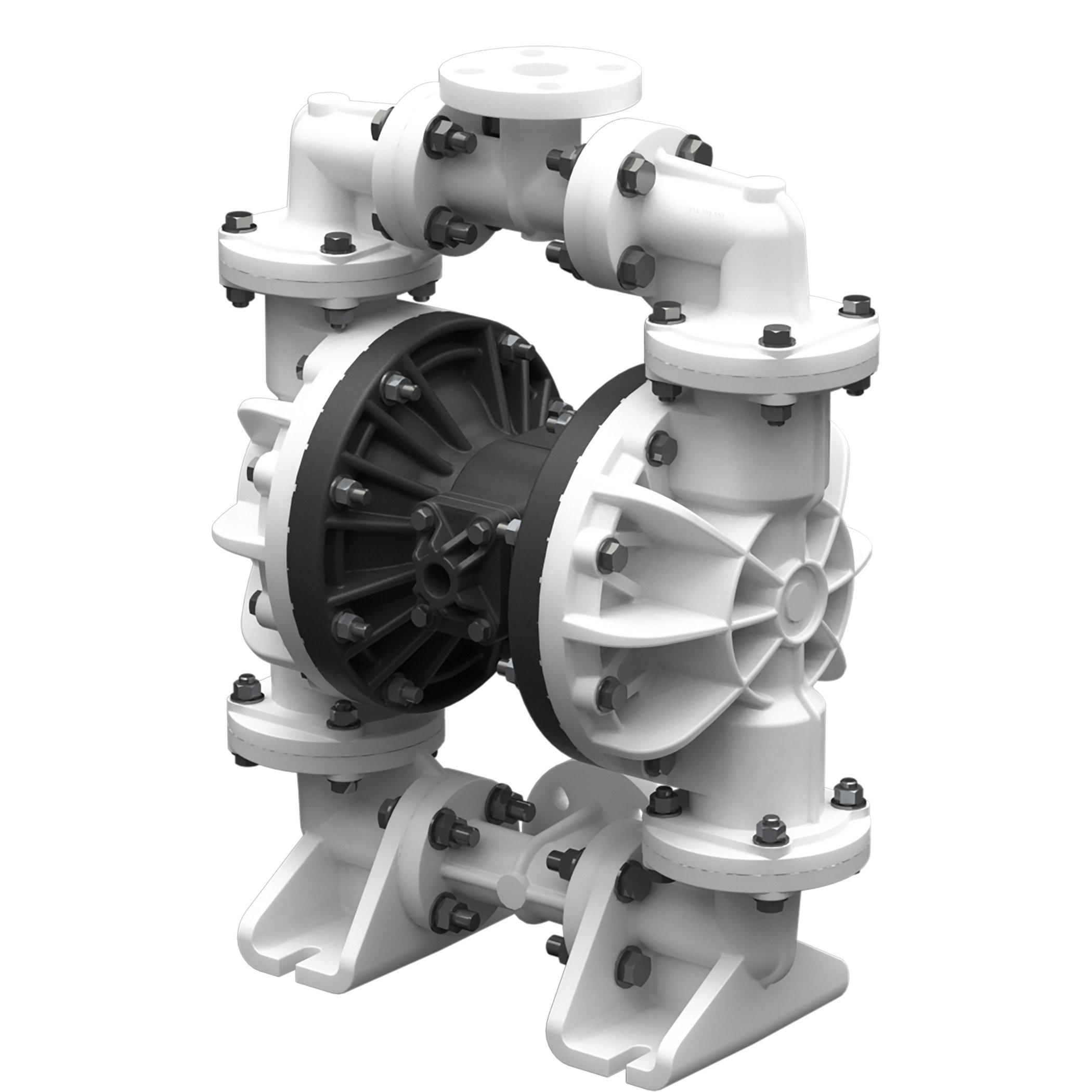

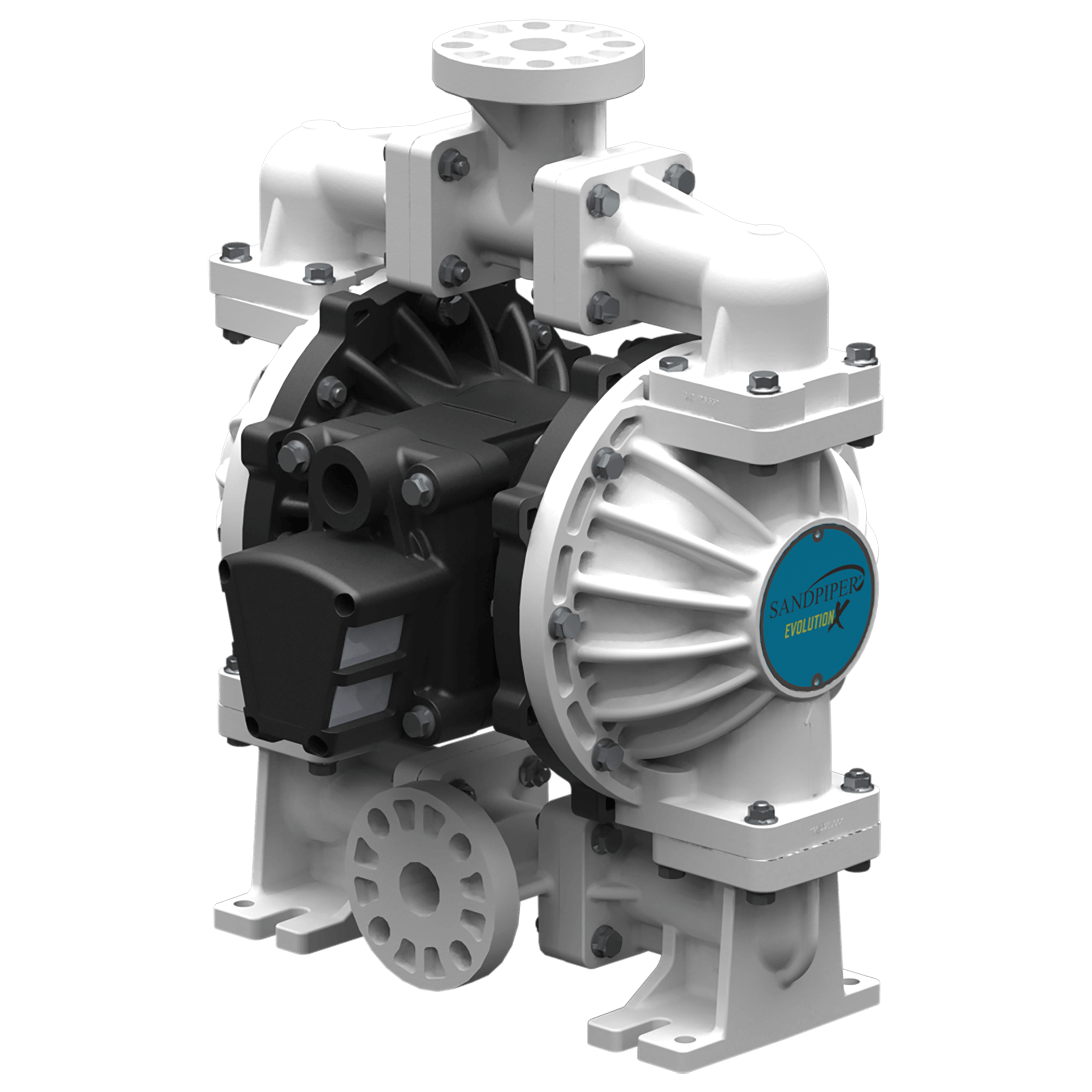

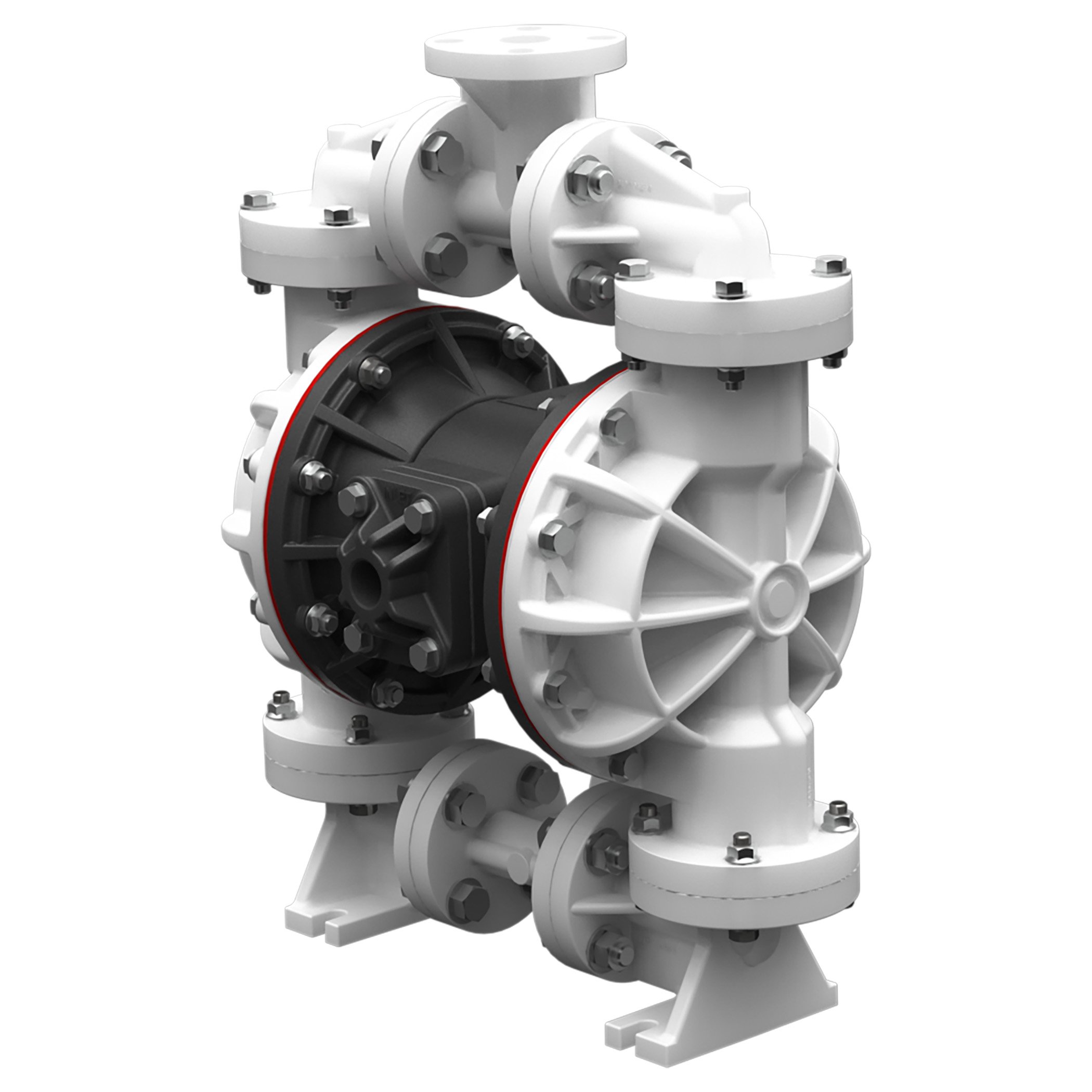

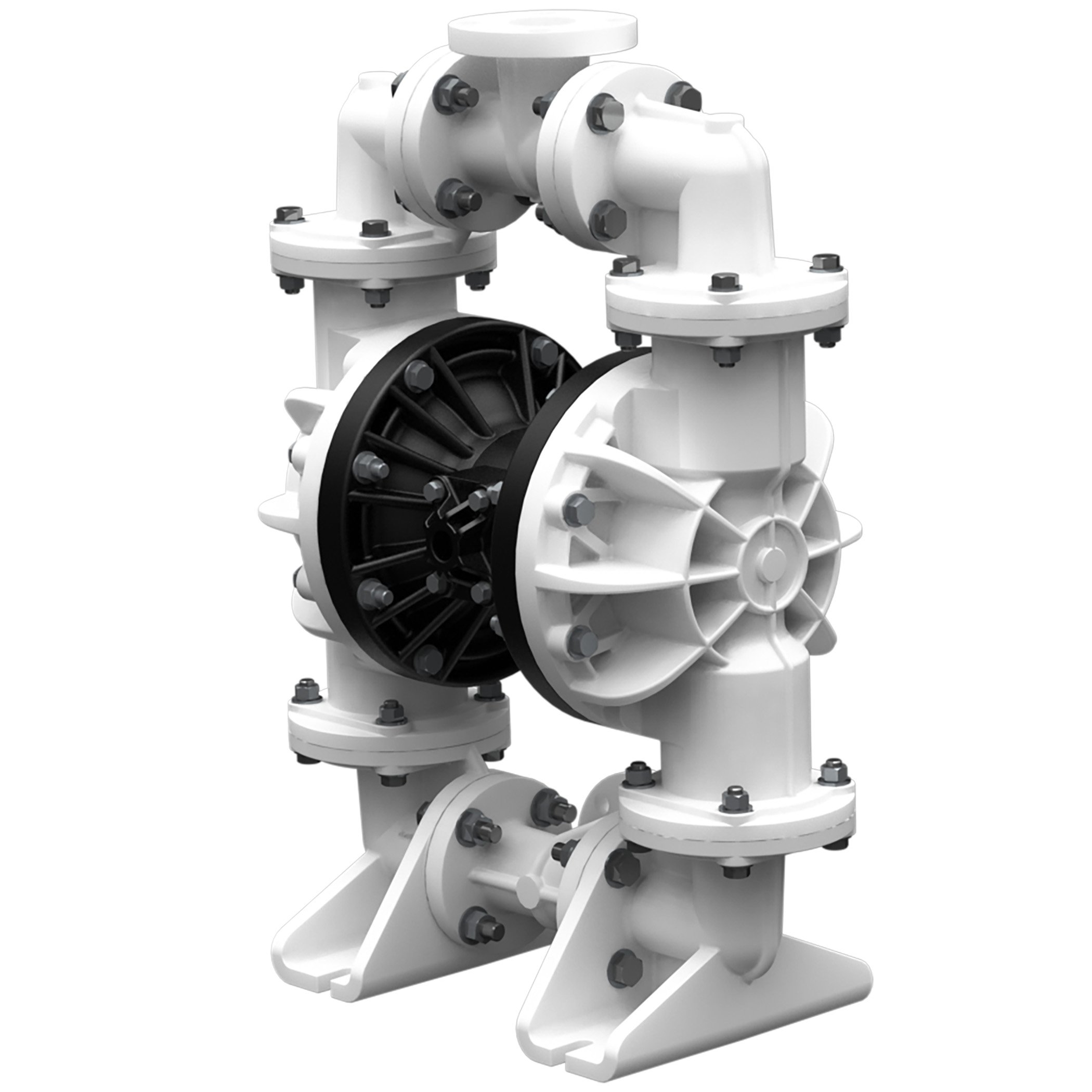

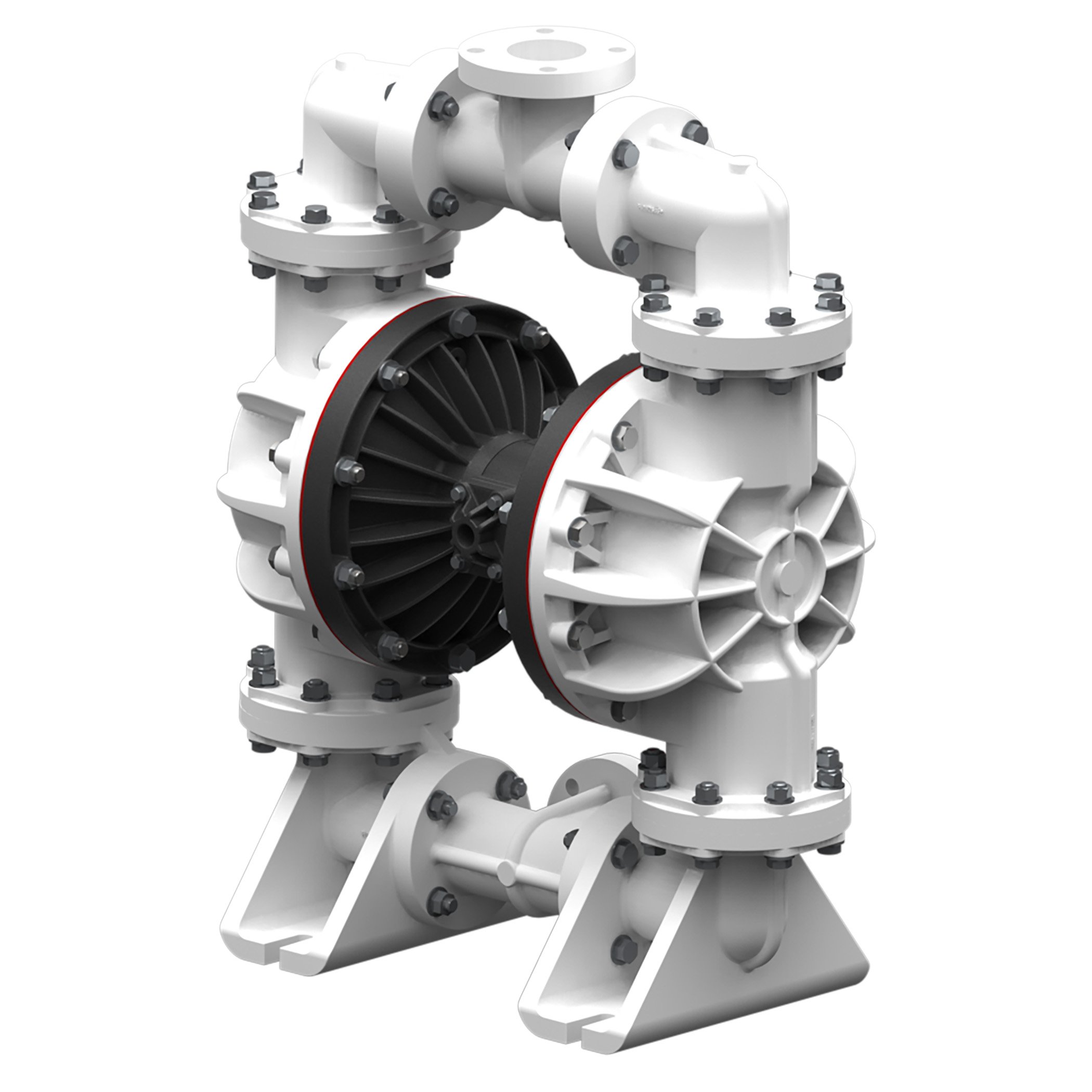

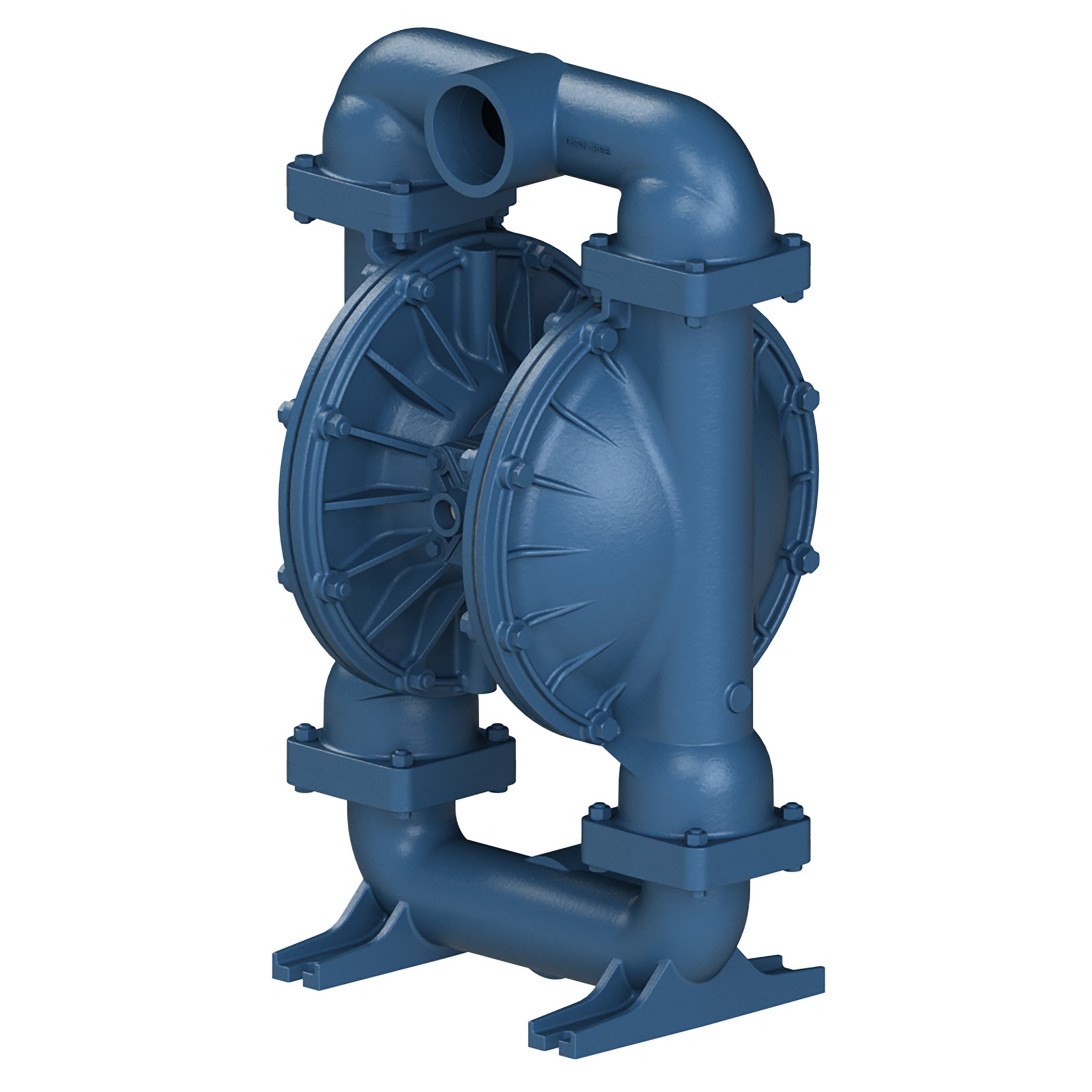

COMMONLY USED AODD PUMPS FOR PAINT, INK AND COATING INDUSTRIES

Click on each pump above to view additional pump details.

Learn more about certifications available and why it’s important to ground your pump.

To determine the chemical compatibility of these pumps with your application, please refer to our Chemical Compatibility Guide.