For more than 55 years, manufacturers across multiple industries that involve hazardous materials have trusted SANDPIPER to protect people, equipment, the environment and the material being pumped.

The SANDPIPER S20 Non-Metallic 2" AODD Pump provides unsurpassed fluid containment in the event a diaphragm is breached.

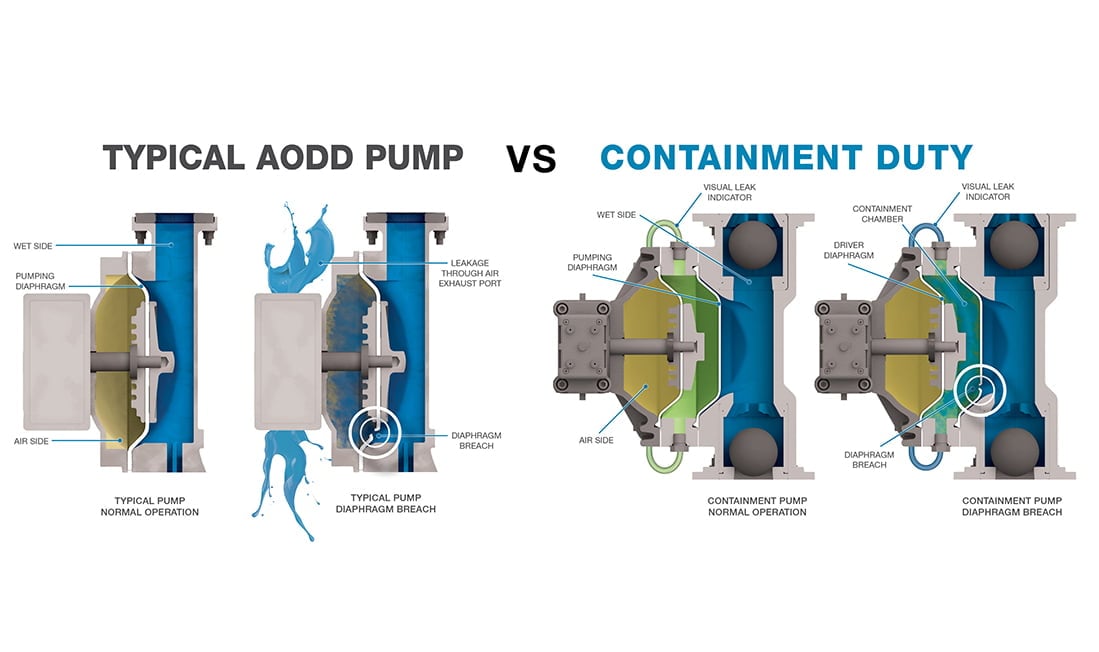

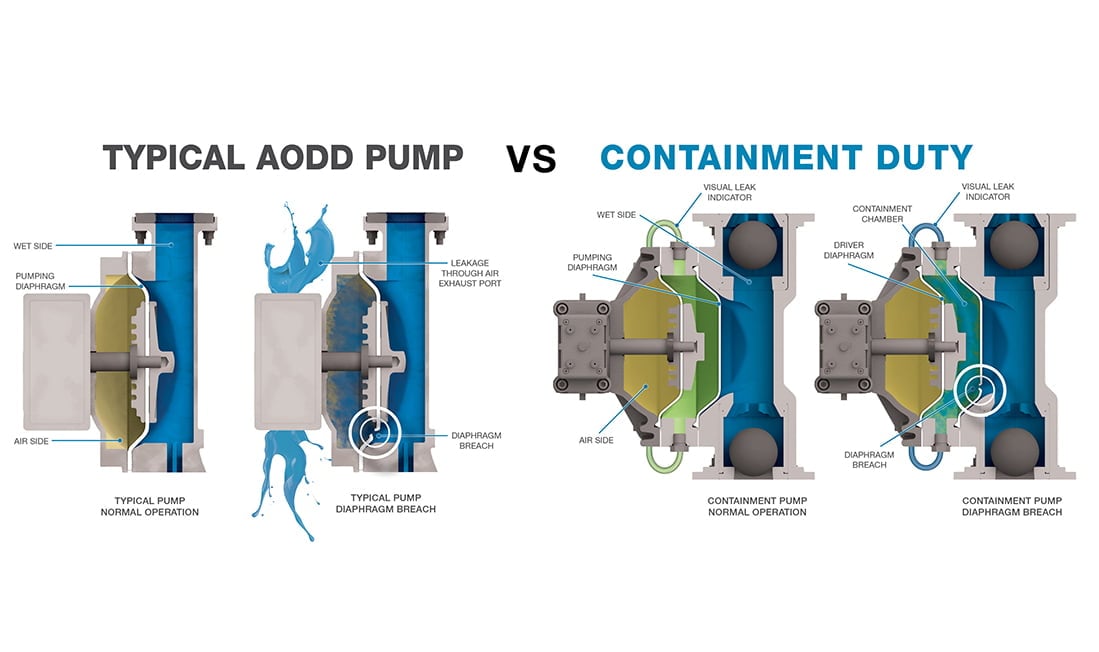

Typical Pump Versus Containment-Duty Pump

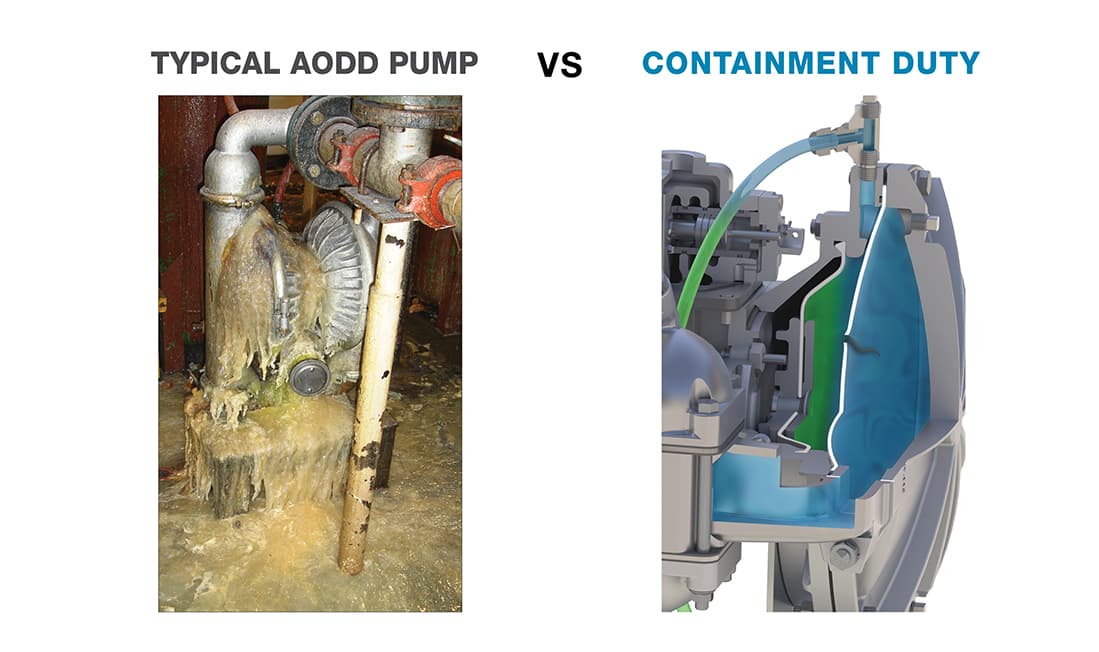

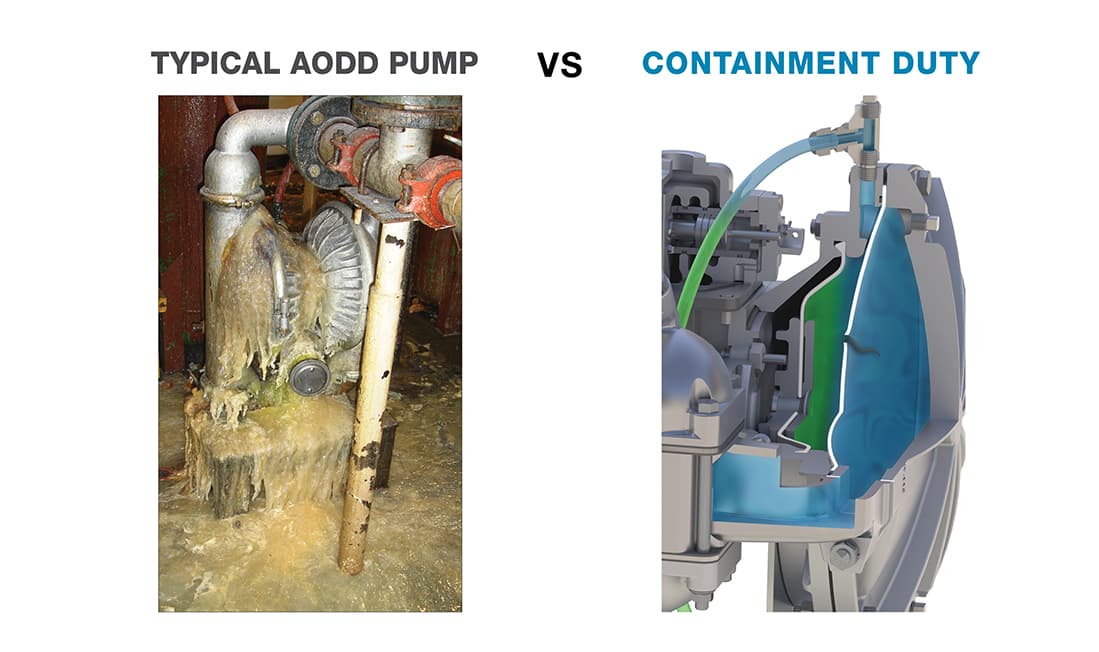

In a typical AODD pump, when the pumping diaphragm is breached, the fluid enters the air distribution system and escapes into the environment through the muffler, requiring immediate service.

In a containment-duty pump, when the pumping diaphragm is breached, the fluid enters the containment chamber and visual indicator sight tubes, alerting the user. The fluid is fully contained so the pump can continue running until the operation is complete or maintenance can be scheduled.

This leak-free pump is designed to be driven by compressed air or nitrogen.

Why Use Containment-Duty Pumps?

Environmental concerns: When fluids (like those listed below) escape to the environment, significant time and effort is required on clean up and material recovery. Additionally, the costs of downtime, lost production, manpower, equipment replacement, disposal fees and fines can be excessive. Preventing leaks when handling these substances provides a more efficient operation and avoids the damaging effects of environmental and human exposure to these toxic fluids.

- Paints, inks and coatings

- Adhesives and resins

- Chemicals and petrochemicals

- Oils and hydrocarbons

- Acids, caustics and corrosives

- Plastics and polymers

- Contaminated water and wastewater

- Pesticides and herbicides

- Fertilizers

- Preservatives

- Mercury

- Phthalates

High cost of lost fluid: When fluids (like those listed below) escape to the environment, the cost of losing them is significant. Lost fluid means lost profit.

- Drugs and pharmaceuticals

- Foods

- Cyanotic-based paints

- Precious metal-based fluids

- Cosmetics

- Perfumes

- Printer inks

- Beer and alcohol

- Blood

- Creams and lotions

Fluids that need to be contained: Even non-toxic fluids, like clean water, can create hazards, annoyances and safety concerns if people are in or around the area surrounding a pump when a diaphragm fails. When dealing with toxic and hazardous fluids, the need to contain leaks goes from a nuisance to a critical safety need.

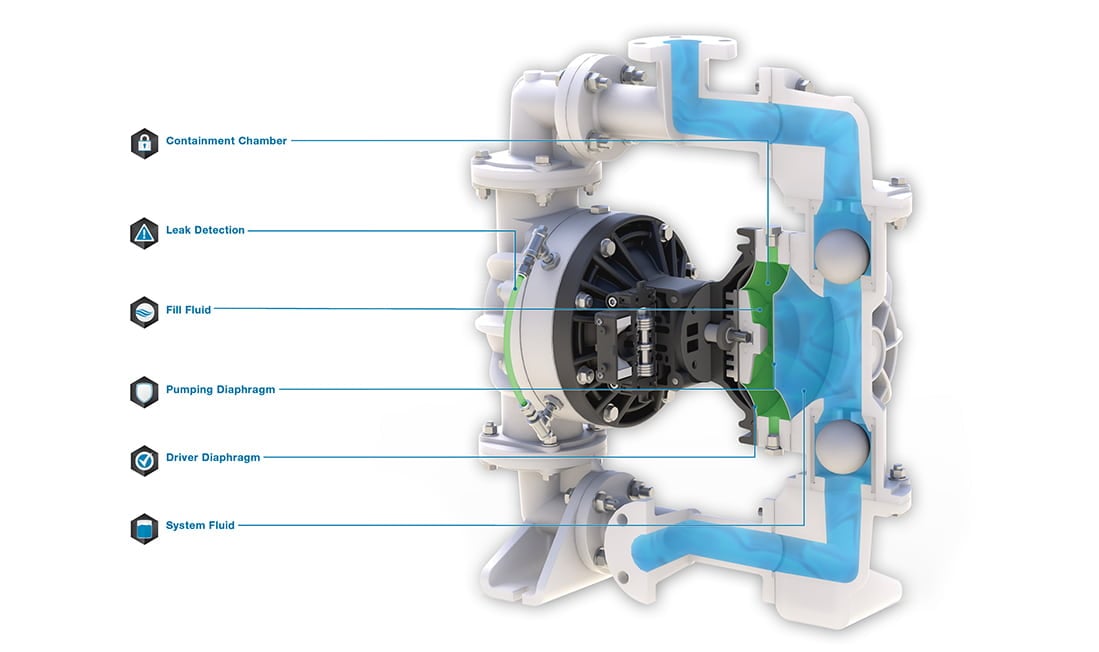

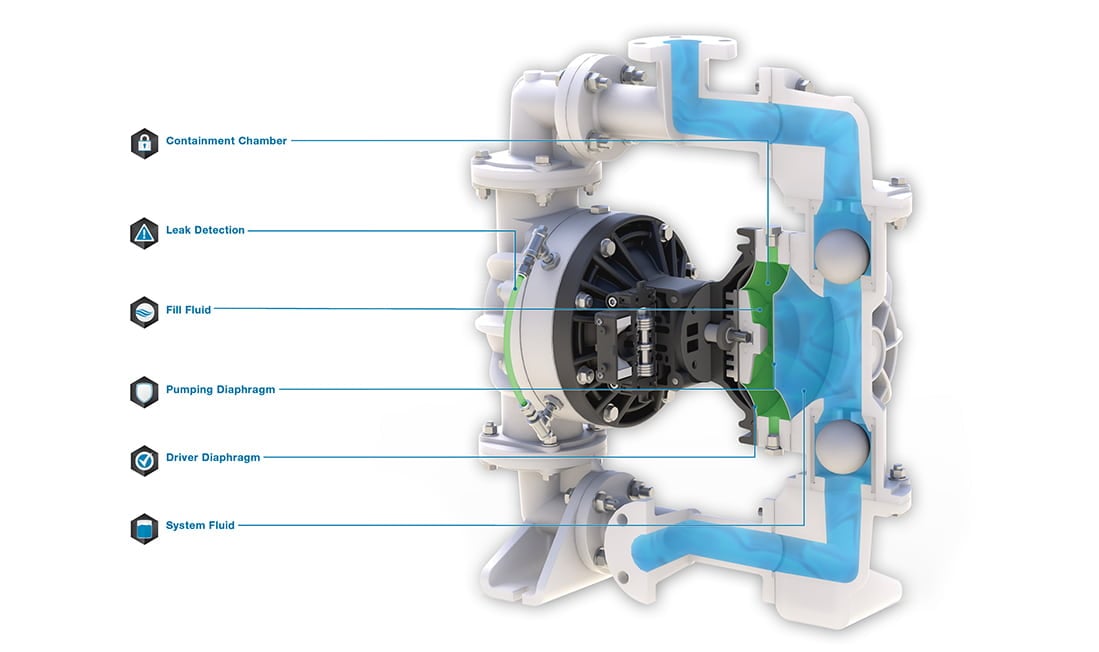

S20 Containment-Duty Pump Features

- Leak detection: All containment-duty pumps are designed to accommodate visual, mechanical and electronic leak detection devices.

- Durability: The durable, bolted construction of the S20 is superior to the clamped-band construction pump, providing exceptional leak-free performance.

- Serviceability: The air distribution system (ADS) is one of the most frequently serviced parts of any AODD pump. Only SANDPIPER's ESADS+ feature allows access to the complete ADS without removing the pump from service. Repair or clean in five minutes (versus 55 minutes for competitors). Additionally, the S20 offers air-side interchangeability with SANDPIPER’s 1" (S1F), 1½" (S15) and 3" (S30) pumps for reduced inventory costs.

- Trusted design: SANDPIPER’s original ADS is fully interchangeable, repairable and inline-serviceable. Other manufacturers frequently change ADS designs, creating issues with interchangeability, obsolete inventory and increased cost of ownership.

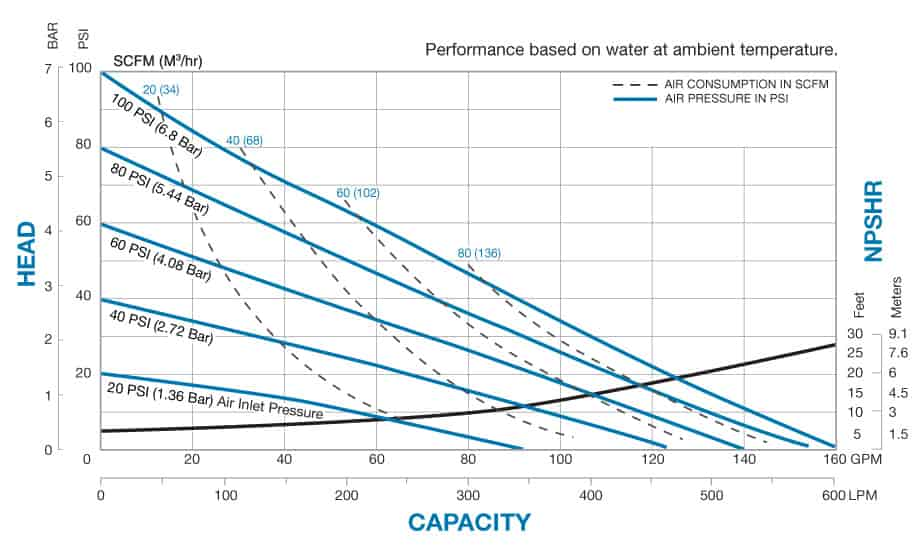

Performance Guarantees

Chemical Compatibility Guide

To determine chemical compatibility with this pump, please refer to our Chemical Compatibility Guide. Material of construction options include: polypropylene and PVDF, with elastomer TPE (thermoplastic elastomers) and PTFE options in diaphragms and check valves.