SANDPIPER pumps are designed with a variety of materials to ensure we have the right pump for your critical application.

We offer engineered pump designs and utilize the highest quality materials to decrease your downtime and increase your pump and system performance. There are two categories of AODD pump materials of construction to consider:

Pump Material Selection

-

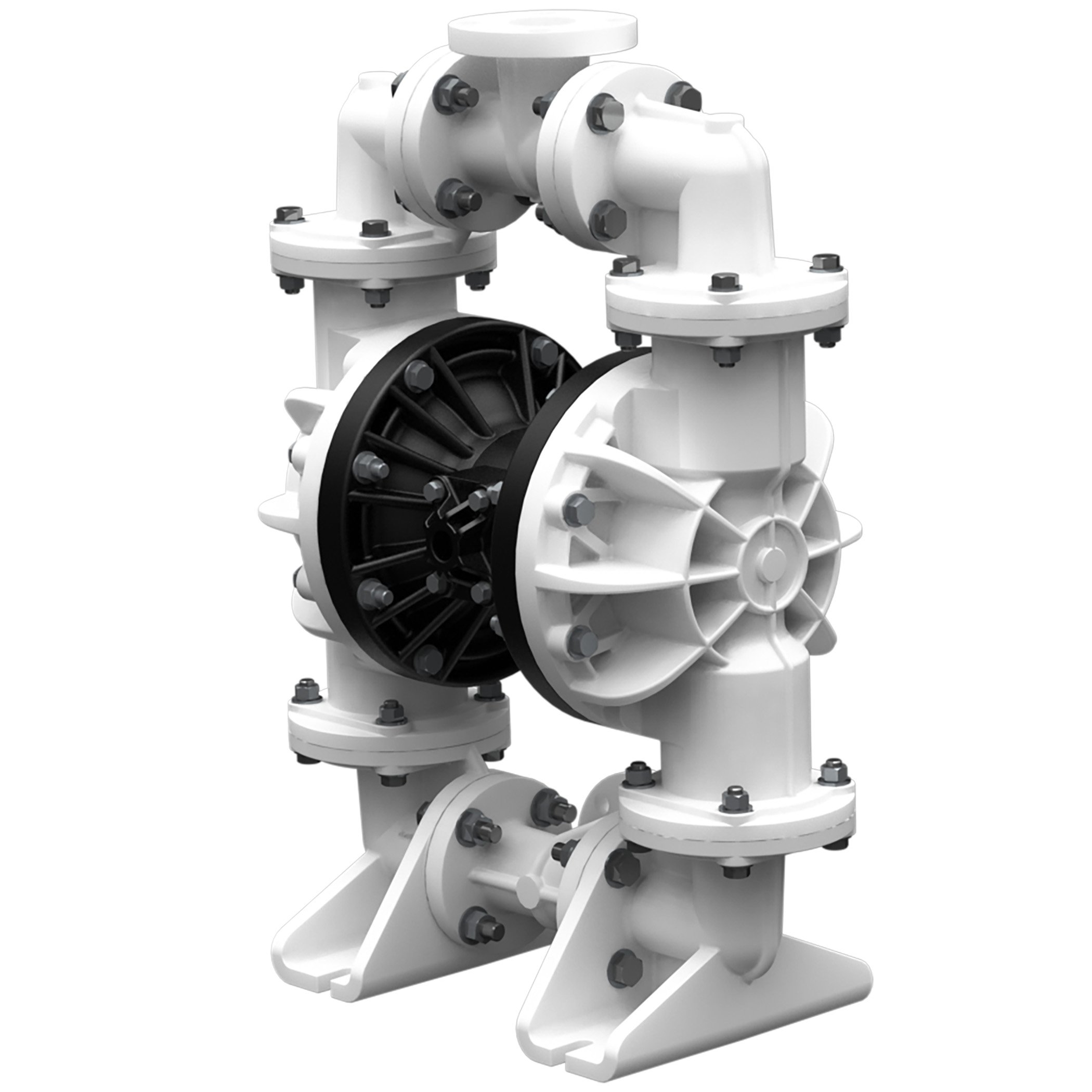

- Metallic – durable and robust for abrasives and slurries

- 316 stainless steel components

- Alloy C

- Hastelloy

- Aluminum

- Cast iron

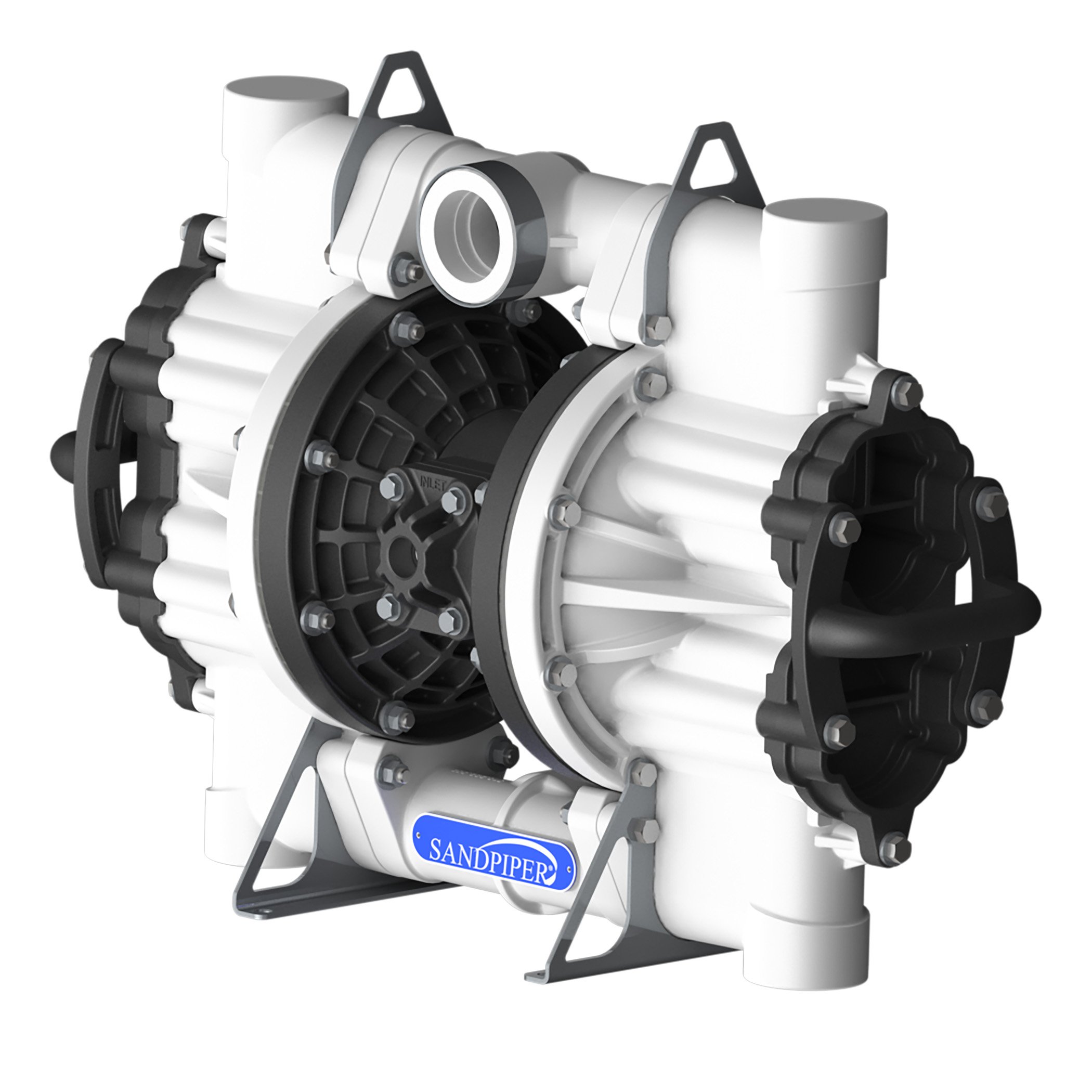

- Non-metallic – robust lightweight design offering a broad range of chemical compatibility

- Polypropylene

- Acetal

- Conductive polypropylene

- Conductive acetal

- Conductive PVDF

- PVDF Kynar

- Nylon

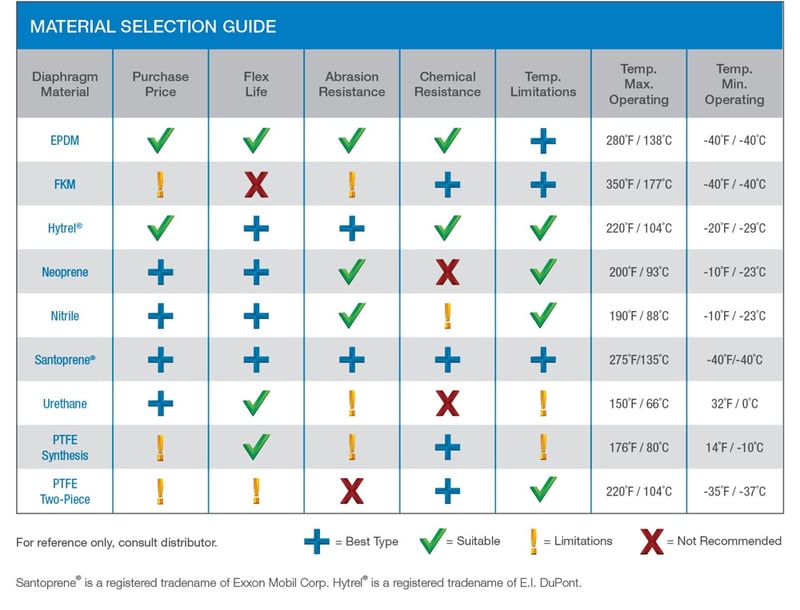

Elastomeric Selection

-

- Buna

- Nitrile

- EPDM

- Delrin

- Hytrel

- Neoprene

- Santoprene

- FKM

- UHMW

- Carbon steel

- PTFE (Teflon)

Pumps for Rugged Applications

Additionally, for rugged applications, SANDPIPER offers heavy-duty flap and ball valve product lines.

Heavy-duty flap valve pumps are offered with thick manifold and chamber walls. This allows for greater wear resistance when pumping solids and solids-laden slurries, providing extended service life. Some heavy-duty models come with down-ported configurations to provide exceptional durability and life in these demand solid and slurry applications.

For fluids containing settling, suspended and floating solids, trust the performance and reliability of SANDPIPER heavy-duty ball valve pumps.

Additional AODD Pump Parts

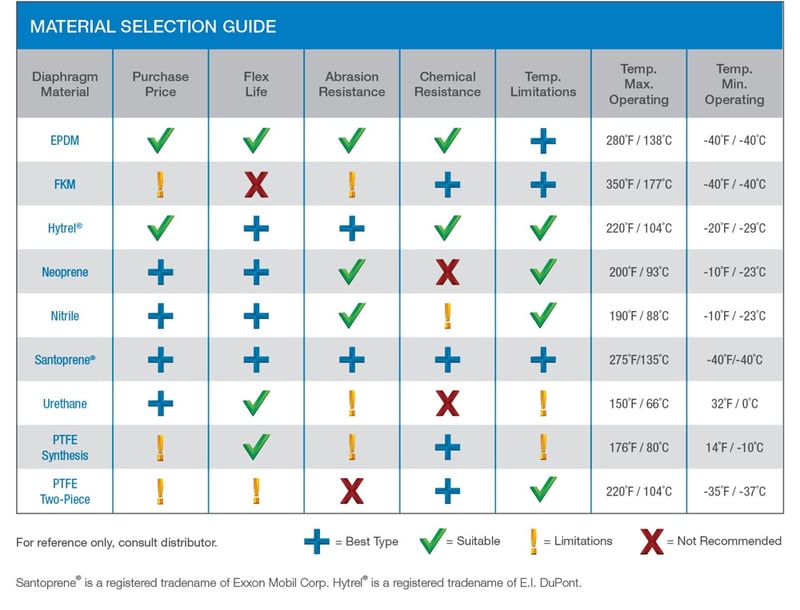

To choose the perfect pump for your application, you also need to consider pump diaphragms, diaphragm wear pads, check balls, flaps and seats.

Pump Diaphragms

Get the maximum longevity out of your SANDPIPER pump by selecting the appropriate diaphragm for your application.

The Synthesis™ diaphragm is an exclusive SANDPIPER technology. Uniquely designed as a premium one-piece diaphragm, it creates optimum conditions for high-performance pumping and reliability. You can expect longer service life and reduced maintenance costs with this premium diaphragm. Features include:

- Temperature range: 14°F to 176°F (-10°C to 80°C)

- Torque-free installation: simply hand-turn into position

- One-piece composite design with 100% PTFE on the wetted side bonded to a nitrile rubber backer (NRB) with an integrated diaphragm plate

- No center hole: for superior leak-free operation and installation

- No outer diaphragm plate abrasion due to trapped fluids

- Oversized integrated plate supports nearly 50% of the diaphragm through the entire dynamic motion

- Start-up pressure of less than 10 psi on SANDPIPER Synthesis diaphragm versus 25 psi or more on competitive diaphragms

Additionally, SANDPIPER pumps are offered with a standard PTFE diaphragm (a two-piece diaphragm)—a cost-effective solution for a large variety of pumping applications. Some of the main features of this diaphragm include:

- Wide range of pressure capabilities

- Variety of materials available

- Proven performance over years of testing

Diaphragm Wear Pads

Extend diaphragm life by reducing the frictional stresses associated with the outer diaphragm plate.

Please consult your distributor or factory experts for additional details.

Check Balls, Flaps and Seats

- Check balls are available in standard and weighted options. Weighted check balls are used in applications containing thick, viscous fluids.

- Flaps are ideal for solids-laden fluids.

- Check valve seats are available in a variety of materials based on your application and chemical compatibility.

Chemical Compatibility

To determine chemical compatibility with your pumping application, please refer to our Chemical Compatibility Guide.