If you’re a plant manager, there are probably three things you think about every day:

- Performance

- Schedule

- Budget

All of these must come together so you can properly do your job. If something happens, like equipment failure, it has a ripple effect throughout the entire plant and could even result in process shut down. Additionally, if a machine isn't performing at its best, it slows down production. If production is slowed, the budget takes a hit.

You don’t have time for drawn-out process issues, repairs or expensive repair parts.

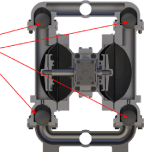

Luckily, if you work with air-operated double-diaphragm (AODD) pumps, you don’t have much to worry about. AODD pumps are known as the reliable workhorses of industry and are likely to provide years of dependable, consistent service.

In the unlikely event a pump does fail, it can usually be fixed quickly for a reasonable cost. To avoid downtime, plan ahead and be aware of the common ways to troubleshoot an AODD pump.

The 6 Common Causes of AODD Pump Issues

Issue #1: The pump will not cycle, or it cycles and then stops.

Listen to your pump. If there is no air exhaust or continuous exhaust air with no cycling, you may have a problem.

Troubleshooting Tip #1

Make sure the air supply pressure exceeds the system head.

The fix: Increase the inlet air pressure to the pump. Most diaphragm pumps are designed for 1:1 pressure ratio at minimum flow.

Remember: Inlet air pressure must exceed the system head.

Troubleshooting Tip #2

Check the pump’s air distribution system.

The fix: Refer to the air valve section of the pump’s service manual. Disassemble and inspect the main air distribution valve and pilot valve. Check for bent or missing pilot valve actuators. Also, check the air valve and intermediate gaskets to ensure proper alignment. Additionally, ensure that the parts are assembled properly in accordance with the manual diagram and assembly steps.

Troubleshooting Tip #3

Check for pumped fluid in the air exhaust muffler.

The fix: Disassemble the pump chambers and inspect for diaphragm rupture or loose diaphragm plate assembly.

Troubleshooting Tip #4

Check the air exhaust muffler. The pump may experience a gradual reduction in flow prior to a complete blockage.

The fix: Remove the muffler screen to clean or de-ice. When completed, reinstall the muffler screen.

Troubleshooting Tip #5

Make sure the pumping chamber isn't blocked.

The fix: Disassemble and inspect the wetted chambers of the pump. Remove or flush any obstructions.

Troubleshooting Tip #6

Make sure the discharge line isn't blocked.

The fix: Check for an obstruction in the pump valves, manifold or a closed discharge line valve.

Issue #2: The pump cycles, but it produces no flow.

Listen to your pump. If the exhaust air produces the sound of a smooth and even rhythm but produces no flow, you may have a problem.

Troubleshooting Tip #1

Make sure there isn't excessive suction lift in the system.

The fix: For lifts exceeding the published limit for the given pump, usually 20 feet (6 meters) or less, fill the pumping chambers with liquid to prime the pump.

Troubleshooting Tip #2

Make sure the suction line isn't blocked.

-1.png?width=350&name=Tip2(2)-1.png)

The fix: Remove or flush any obstruction. Check and clear all suction screens and strainers.

Troubleshooting Tip #3

Look for suction side air leakage when the liquid source is below the pump.

-1.png?width=300&name=Tip3(2)-1.png)

The fix: Visually inspect all suction side gaskets and pipe connections.

Troubleshooting Tip #4

Look for worn, misaligned or obstructed check valves or check valve seats.

The fix: Visually inspect check valves and seats for wear or chemical attach and ensure proper seating. Replace as required.

Issue #3: The pump cycles, but its flow rate is unsatisfactory.

Listen to your pump. If the exhaust air is cycling much faster than normal, you may have a problem.

Troubleshooting Tip #1

Look for excessive suction head pressure in the system.

The fix: For flooded conditions exceeding 10 feet (3 meters) of liquid, install a back-pressure device in the air exhaust.

Troubleshooting Tip #2

Make sure the air supply pressure or volume does not exceed system head requirements.

The fix: Decrease inlet air pressure and volume to the pump as calculated on the pump’s published performance curve.

Troubleshooting Tip #3

Make sure your suction line isn’t too small or somehow restricted.

-1.png?width=300&name=Tip3(3)-1.png)

The fix: Install a larger suction line and connection. Your pump needs to meet or exceed connection recommendations.

Troubleshooting Tip #4

Make sure there is no suction side air leakage or air in the product.

-1.png?width=300&name=Tip4(2)-1.png)

The fix: Visually inspect all suction side gaskets and pipe connections.

Troubleshooting Tip #5

Make sure the air exhaust muffler isn't restricting the air flow through the pump.

The fix: Remove the muffler screen, clean or de-ice and then reinstall.

Troubleshooting Tip #6

Make sure the discharge manifold or line isn't restricted.

-1.png?width=300&name=Tip6(2)-1.png)

The fix: Check for restrictions, product buildup or semi-closed discharge line valves.

Troubleshooting Tip #7

Restricted or undersized air line

The fix: Install a larger air line and connection. Air line piping should be the same size as the connection on the air inlet to the pump. Both pressure and volume need to be considered when sizing. Consult owner’s manual for pump requirements

Issue #4: The pump cycle is unbalanced.

Listen to your pump. If you hear an out-of-rhythm exhaust, you may have a problem.

Troubleshooting Tip #1

Make sure the check valves are unobstructed.

The fix: Disassemble the wet end of the pump and manually dislodge any obstruction in the check valve pocket.

Troubleshooting Tip #2

Make sure there are no worn or misaligned check valves or check valve seats.

The fix: Inspect check valves and seats for wear and proper seating. Replace as required.

Issue #5: The pump cycle produces excessive vibration.

Listen to your pump. If you hear excessive pipe vibration and check valve chatter, you may have a problem.

Troubleshooting Tip #1

Look for rigid pipe connections to the pump.

The fix: Install flexible connectors on the pump suction and discharge and install a pulsation dampener on the discharge side of the pump.

Issue #6: The pump's diaphragm fails prematurely (prior to 10 million strokes).

If this happens, the likely culprits are:

- Temperature: The product being pumped is too hot or too cold.

- Chemical resistance: A chemical being pumped isn't compatible with your pump.

- System conditions: The system conditions are not ideal for your pump. Refer to the pump manufacturer’s general pump installation recommendations.

Troubleshooting Tip #1

Check your pump’s diaphragms for cracks, bubbles, melting, or other deformation.

The fix: Determine the correct elastomer for the process temperature. Adjust the process temperature to be within the published operating range of the selected diaphragm. Consider alternate diaphragm materials if the temperature cannot be adjusted.

Troubleshooting Tip #2

Check your pump’s diaphragms, check balls and gaskets for cracks, bubbles, erosion or other deformation.

The fix: Determine the correct elastomer for the process based on the Warren Rupp / Sandpiper corrosion guide.

Troubleshooting Tip #3

Look for wear on the air side of the diaphragms. Look for diaphragm bolt holes that have become deformed and are oval-shaped.

The fix: Install a back-pressure device on the air exhaust side.

Choosing a Pumping Partner

Though AODD pumps are known for their “set it and forget it” qualities, they need to be properly maintained. Like any piece of equipment, AODD pump parts can prematurely fail if not operated properly.

To avoid unplanned downtime, it’s important to pick a pump manufacturer that offers exceptional technical guidance.

For more than 50 years, SANDPIPER’s expert service has supported customers throughout the life of their pumps. We provide the best solutions for your most difficult pumping challenges, and our accessories ensure your systems perform optimally.

That's why you can trust SANDPIPER to provide the very best pumping equipment to solve your most challenging application needs. Have application-specific questions you need answered? Reach out and contact us today, find a local distributor, or leave your question as a comment below.