Meat and poultry production requires tough and reliable pumps that can handle blood, organs, fat and waste from animals.

Meat and poultry production requires tough and reliable pumps that can handle blood, organs, fat and waste from animals.

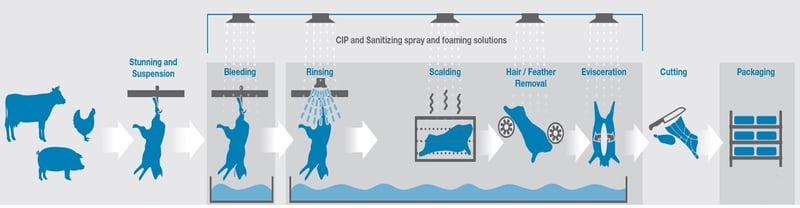

From pigs, cattle and sheep to chickens and turkeys, the processing steps are similar.

Every step of the process presents unique pumping challenges. Two of the most common challenges we hear from pump users are:

- Pumps get plugged up with solids from all parts of the process

- Plant water transfer systems and sumps get backed up

In this blog, you’ll learn what many meat and poultry processing companies are doing to solve common pumping problems.

Meat Processing Applications

Typical Blood Collection and Transfer

- Harsh and messy

- Solids find their way into the process and become trapped in pumps

- Collection areas and passages need to flow without backing up to ensure cleanliness and safety

- Abrasive properties of blood can wear through conventional pump walls and chambers

- Shear forces cause frothing and damage downstream blood products

Scalding, De-Hairing and De-Feathering

- Hair and feathers clump-up and are difficult to pass through conventional pumps

- Hair and feathers fall onto the floor and into drains where they create backups

- Pumping equipment must reliably handle everything from clean water to water containing solids

Evisceration (Removal of Internal Organs)

- Harsh and messy

- Parts are separated for later processing

- Collection areas and passages need to flow without backing up to ensure cleanliness and safety

- Transfer of casing waste, organs, feet, heads, beaks, etc. is challenging for typical pumps

Process Water

- Solids of various sizes and shapes enter the water stream

- Sumps, troughs and collection areas need to flow

- Floor drain grating does not prevent solids from entering plant water drain systems

- Submersible pumps are challenging to use and maintain

Washdown and Sanitation

- Variety of chemicals, detergents and caustics used

- Equipment materials need to be properly selected to ensure compatibility, safety and reliability

- Risk of electrical shock

Wastewater

- Dissolved Air Flotation (DAF) systems and other treatment technologies create viscous and chunky sludge

- Must be able to reliably pump water containing solids with air pockets

- Must be able to pump viscous fluids at high capacity

Pumps Used in Meat and Poultry Processing

| Pump | Advantages and Disadvantages |

|

Centrifugal

|

Advantages

Disadvantages

|

|

Progressive Cavity

|

Advantages

Disadvantages

|

|

Air-Operated Double-Diaphragm (AODD)

|

Advantages

Disadvantages

|

What if There Was One Pump That Could Do It All?

There is! For decades, the meat and poultry processing industry has trusted SANDPIPER’s heavy-duty flap valve pumps to solve common clogging challenges, from blood collection to wastewater management. The flaps allow solids as large as the pipes to pass through, including feathers, pig hair, casing room waste, organs, process water solids and wastewater solids and sludge.

These pumps, which have been the workhorse of the meat and poultry processing industry for over 50 years, feature:

- Thick, robust chambers that withstand abrasive blood flow

- Bolted construction for robust, leak-free performance

- Top suction/bottom discharge for gravity-assisted solids transfer

Compared to AODD ball valve pumps and other rotating pump technologies, heavy-duty flap valve pumps are optimized to enhance performance and efficiency.

- Highest flow capacity (1”, 2” and 3” pumps available)

- Lowest air consumption in its class

- If you can reduce how much air you use, you’re going to reduce your carbon footprint.

- No reduction in performance as the pump ages

- Minimal flow velocity changes for superior handling of thick, viscous fluids

SANDPIPER’s patented exclusive externally serviceable air distribution system (ESADS+) allows for complete access to the main air and pilot valves without removing the pump from service.

Need a Meat & Poultry Processing Pump?

SANDPIPER has a complete portfolio of AODD pumps tailored to the unique rigors and severe applications of meat and poultry processing. From blood collection to wastewater management, SANDPIPER is here to help.

We’re capable of providing pumping solutions for the meat processing and rendering industry with high-quality, cost-effective products backed by best-in-class warranties and certifications, including 3-A, FDA and the EC 1935/2004 Food Contact Materials Standard.

For more information on our selection of AODD pumps for meat and poultry processing, visit our Pumps page.