Air-operated double-diaphragm (AODD) pumps are used a lot in the making of batteries.

Within the battery-making process, there are aggressive and hazardous chemicals, abrasive slurries, and high viscosity mixtures. AODD pumps are equipped to handle them all.

Because AODD pumps lend themselves very well to pumping the slurries and chemicals that are used in making batteries, they’re a great candidate for recycling batteries as well.

In this blog, we’ll discuss lithium-ion battery recycling and what makes AODD pumps, specifically flap valve pumps, perfect for this type of application.

Recycling Lithium-Ion Batteries

The power that we use on a daily basis is coming from batteries more than ever before. Lithium-ion batteries are a big part of this movement. The shift to lithium-ion battery power is most impactful in electric vehicles (EV).

A projected surge in EV sales means that researchers must think about conserving natural resources and addressing battery end-of-life issues.

Just how many batteries will need to be recycled? With global sales of EVs expected to climb from 1.7 million in 2020 to 26 million in 2030, it’s easy to imagine we’ll soon be flooded in spent batteries. If projected trends for handling these spent batteries hold, most of those batteries may end up in landfills, even though lithium-ion batteries can be recycled.

Batteries, especially lithium-ion batteries, pose a very serious fire risk when disposed of improperly. When batteries end up at a trash or recycling facility, they often get punctured or crushed, which can damage the separation between the cathode and anode, causing them to catch fire or explode.

Lithium-ion batteries contain valuable metals and other materials that can be recovered, processed, and reused. Heavy-duty flap valve AODD pumps can help in the process.

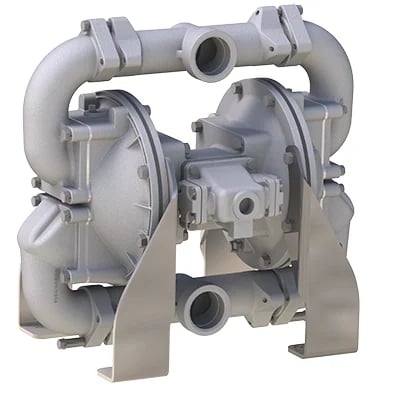

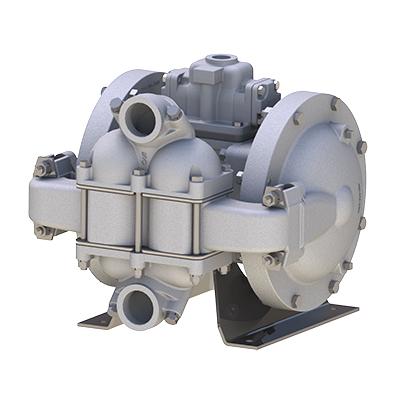

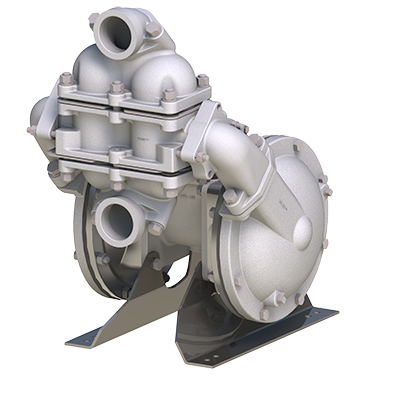

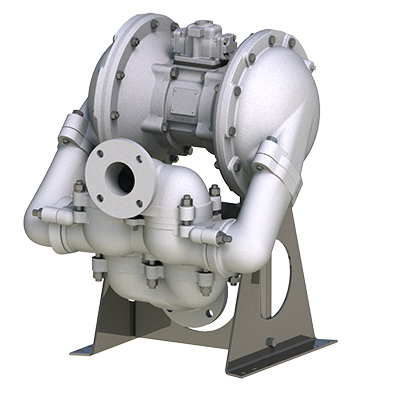

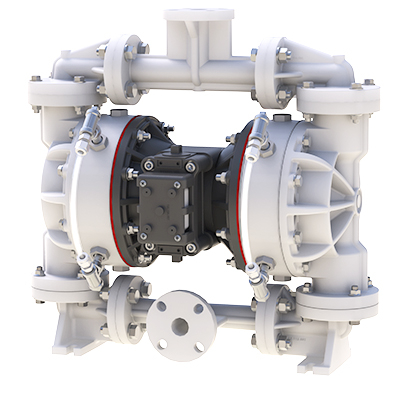

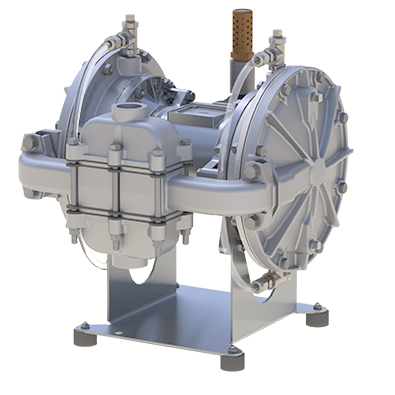

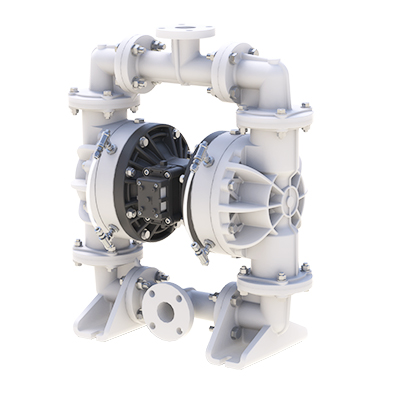

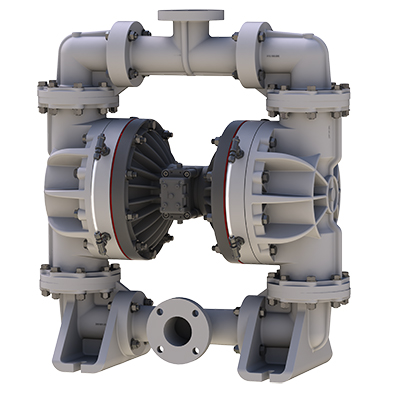

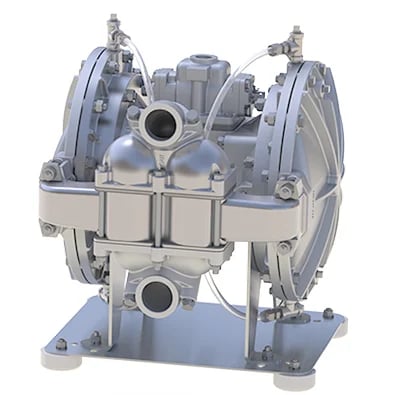

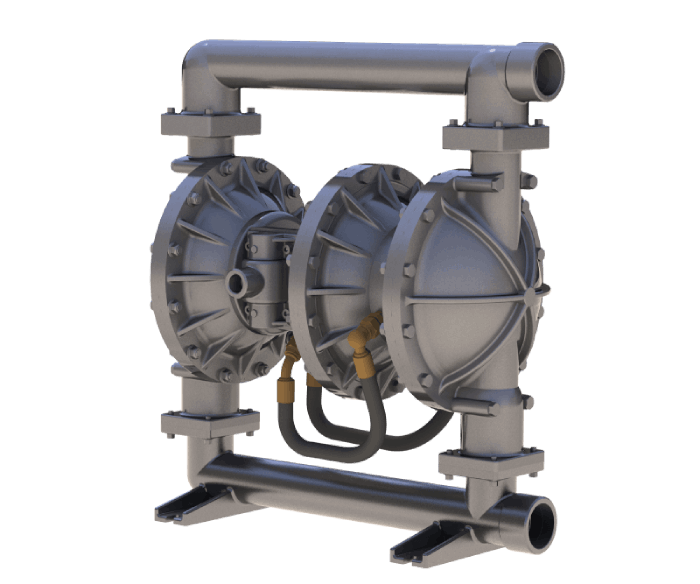

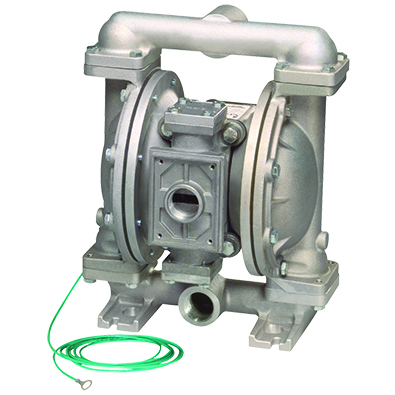

Why Heavy-Duty Flap Valve AODD Pumps?

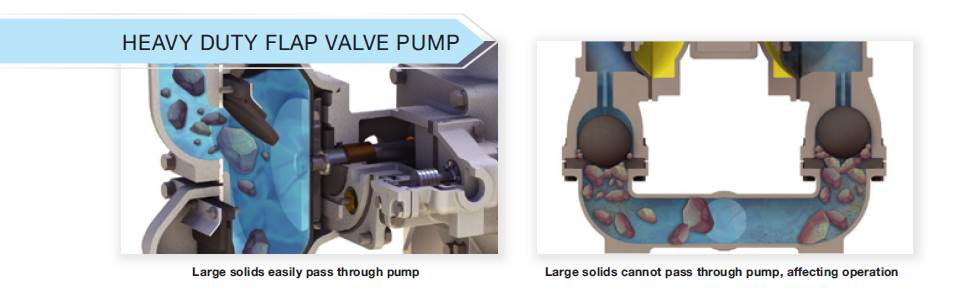

Heavy duty-flap valve pumps are the ideal solution for abrasive slurries, non-suspended and line-size solids requirements. These solids handling pumps are ideal in applications found in lithium-ion battery recycling because of their unique ability to pass non-uniform particulate slurries (i.e., metal, copper, aluminum, plastic) that would commonly clog other pumps.

Compared to AODD ball valve pumps and other rotating pump technologies, heavy-duty flap valve pumps are optimized to enhance performance and efficiency. They have:

- The highest flow capacity (1", 2" and 3" pumps are available)

- The lowest air consumption in their class

- No reduction in performance as the pump wears

- Minimal flow velocity changes for superior handling of thick, viscous fluids

Perfect for Handling Line-Size Solids

- Large flow area to allow up-to-line-size solids to pass directly through the pump

- Bottom discharge design works with gravity to help prevent these solids from settling in the unit

- Eliminate common issues associated with ball valve pumps, where large solids get stuck in the suction manifold or small solids settle in the outer chamber, affecting performance

Quick Access to Serviceable Components

- ESADS+: SANDPIPER’s signature externally serviceable air distribution system (ESADS+) allows for the maintenance and/or repair of both pilot valve and air valve components without removing the pump from service.

Lithium-Ion Battery Recycling Process

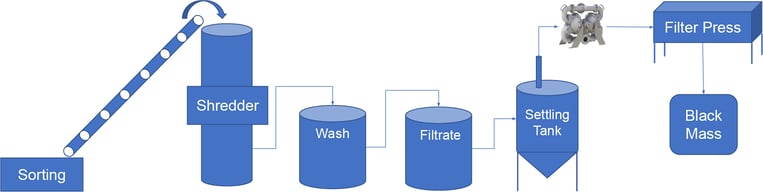

- The batteries are sorted and all excess packaging is removed.

- The belt takes the recyclable material to the top of the shredder, which is under a liquid solution to prevent ignition of the material.

- The material is washed and the plastic is removed.

- The filtering process removes most of the metal foils within the battery.

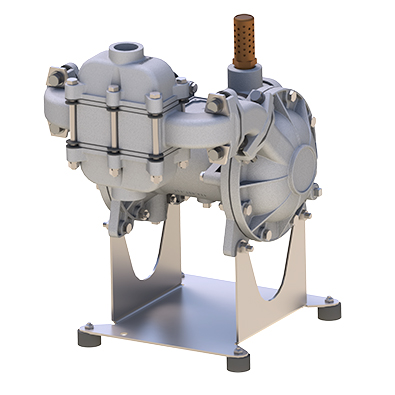

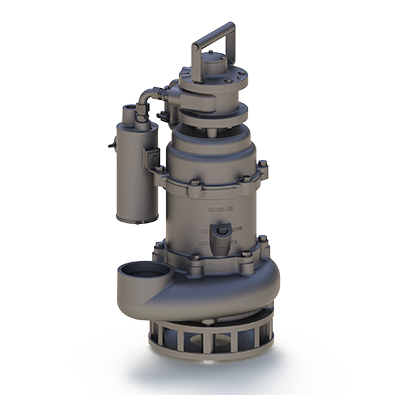

- The metal-laden heavy solids drop to the bottom of the settling tank. The AODD pump is located above the tank, pulling the heavy slurry from the bottom.

- The AODD pump feeds the filter press where the black mass is caked and transported in large bulk bags.

Rely on SANDPIPER for Your Lithium-Ion Battery Recycling Needs

SANDPIPER pumps are manufactured by Warren Rupp, a business unit of IDEX Corporation. With over 55 years of trusted solutions expertise, SANDPIPER delivers best-in-class pumping and engineering innovations for the world’s most difficult and demanding pumping challenges.

Our exclusive designs prevent leaks, allow pumps to be configured in a variety of ways, make maintenance quick and easy, and are durable and high-pressure-capable due to their all-bolted construction.

If you have questions about any of our heavy-duty flap valve pumps, contact us today or reach out to a local distributor.

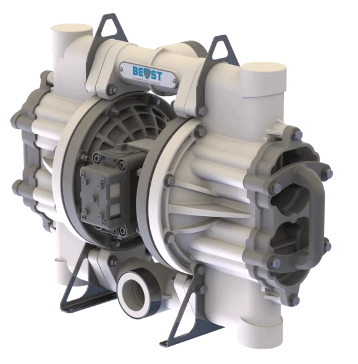

.png?width=358&height=364&name=Rectangle%20pump%20(1).png)

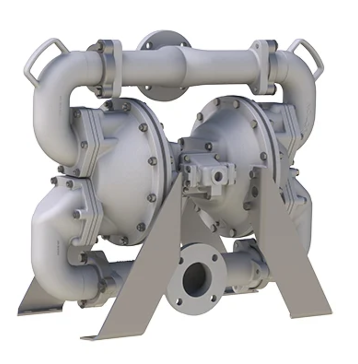

.png?width=660&height=510&name=Cognito%20Front%20view%20(1).png)