Plant personnel like maintenance managers have too much going on for unplanned downtime due to pumping problems. That’s why SANDPIPER experts have created this simple resource to help you follow air-operated double-diaphragm (AODD) pump installation best practices.

Plant personnel like maintenance managers have too much going on for unplanned downtime due to pumping problems. That’s why SANDPIPER experts have created this simple resource to help you follow air-operated double-diaphragm (AODD) pump installation best practices.

In conjunction with following the safety warnings and specifications in your SANDPIPER Pump manual, the tips and videos below will help you get pumping in no time.

6 AODD Pump Installation Recommendations

When you’re installing a diaphragm pump right out of the box, be sure to account for the following six recommendations from SANDPIPER.

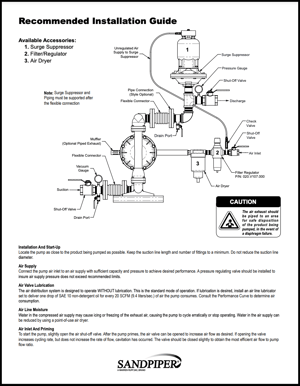

Installation and start-up: Locate the pump as close to the product being pumped as possible. Keep the suction line length and number of fittings to a minimum. Do not reduce the suction line diameter.

Air supply: Connect the pump air inlet to an air supply with sufficient capacity and pressure to achieve the performance level you’re looking for. Install a pressure-regulating valve to ensure air supply pressure does not exceed the pump’s recommended limits.

Air valve lubrication: The air distribution system is designed to operate without lubrication. This is the standard mode of operation. If you need to lubricate, install an air line lubricator set to deliver one drop of SAE 10 non-detergent oil for every 20 SCFM (9.4 liters/sec.) of air the pump consumes. Consult the pump performance curve to determine air consumption.

Air line moisture: Water in the compressed air supply may cause the exhaust air to ice or freeze, causing the pump to cycle erratically or stop operating. To reduce water in the air supply, use a point-of-use air dryer.

Air inlet and priming: To start the pump, slightly open the air shut-off valve. After the pump primes, the air valve can be opened to increase airflow as needed. If opening the valve increases the cycling rate but does not increase the rate of flow, cavitation has occurred. Close the valve slightly to obtain the most efficient airflow to pump flow ratio.

Air exhaust: The air exhaust should be piped to an area for safe disposition of the product being pumped in the event of a diaphragm failure.

4 AODD Pump Wet End & Air End Kit Installation Tips

Rebuilding an AODD pump is not difficult, but there are a few nuances to be aware of. Here are some troubleshooting tips for installing an air end kit or a wet end kit.

- First, make sure you’ve purchased the correct genuine SANDPIPER wet end or air end kit for your pump. You can identify the correct kit on the pump’s metal serial number tag, which indicates the parts information for the pump. You can also find the correct kit information online using our pump kit lookup tool or in your pump’s service and operating manual.

- There is a reason these parts come as kits. It’s important to remove all consumable parts, such as gaskets, U-cup seals, and O-rings, and replace them with new ones during a rebuild. You’ll save yourself time, hassle, and labor costs in the long run.

- During the disassembly and reassembly process, take the time to inspect a metallic pump’s chambers, manifolds, and outer and inner plates for scaring, scratching, material buildup, or damage. These things can be cleaned up with emery paper, crocus cloth, or fine sandpaper. Repair or replace them if necessary. Also, check the casting for wear.

- When you install your new components, always hand tighten screws in a cross pattern, and then torque them according to the specifications outlined in the pump’s service and operating manual.

For more AODD pump installation and troubleshooting information, visit the Technical Resources section of our website or check out AODD pump troubleshooting posts on our blog. You can also reach out to a SANDPIPER expert or contact your authorized SANDPIPER distributor with questions anytime.