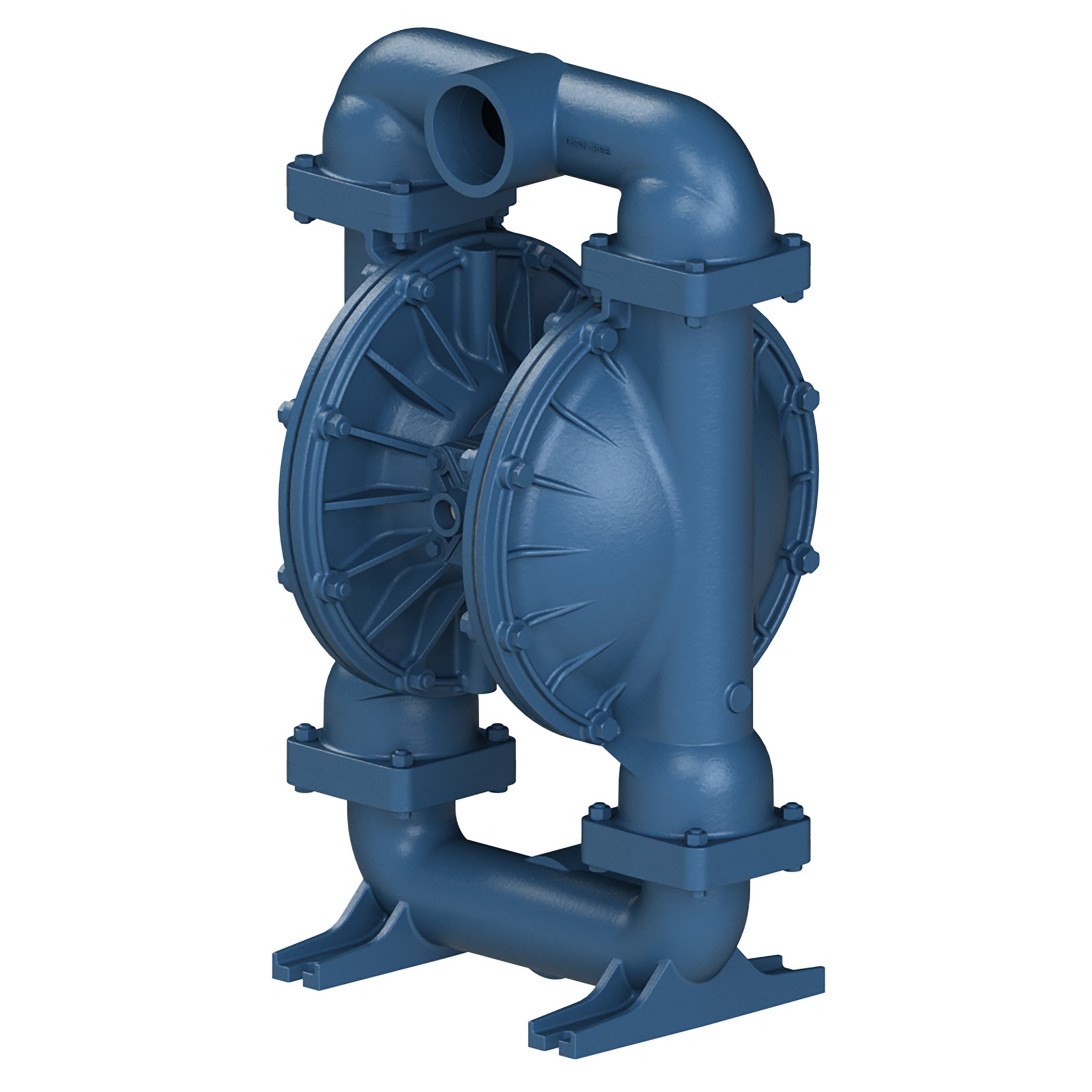

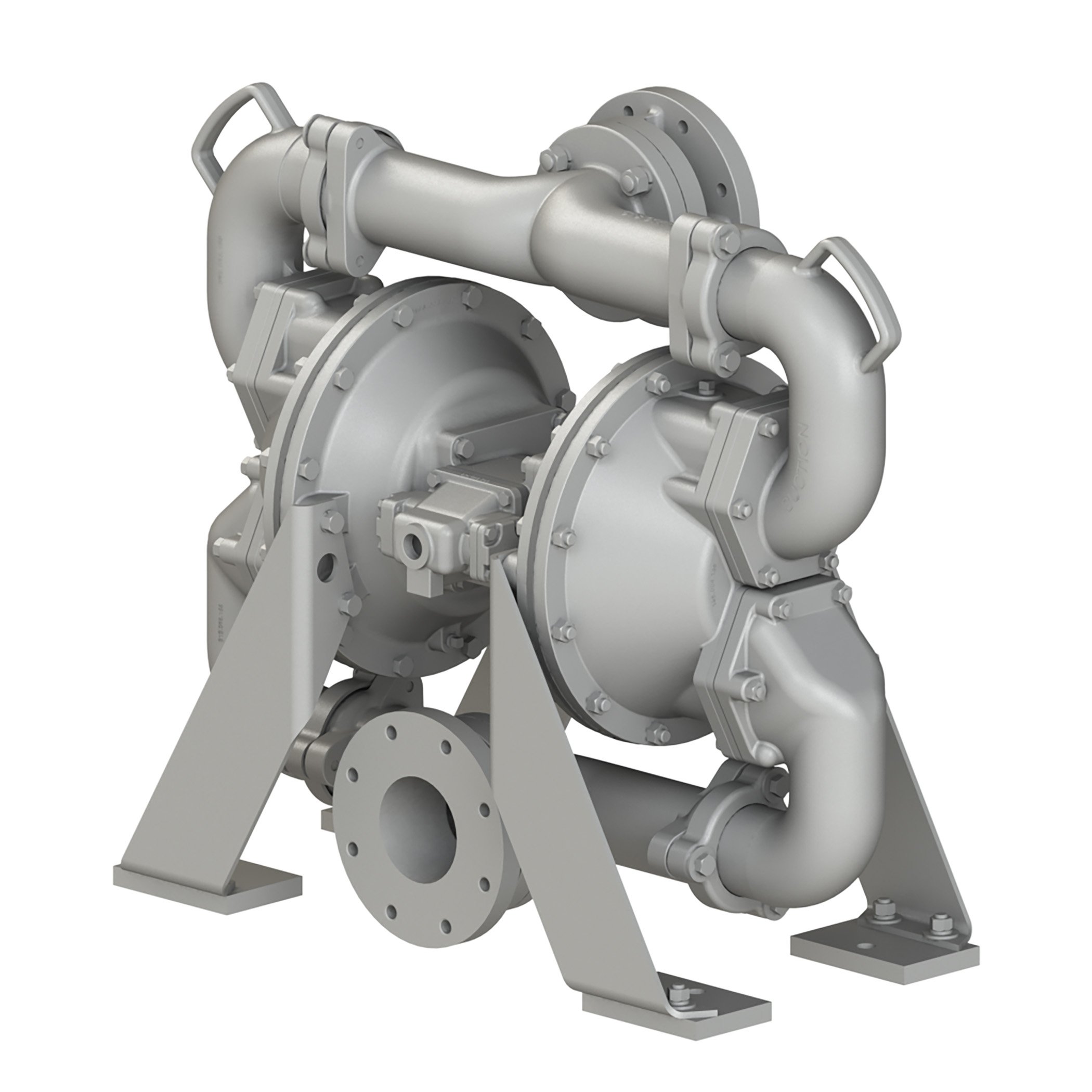

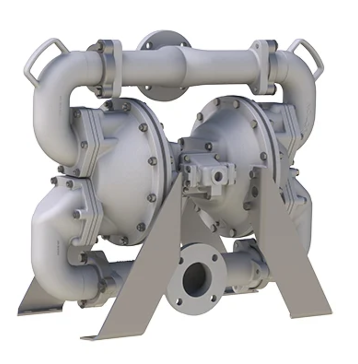

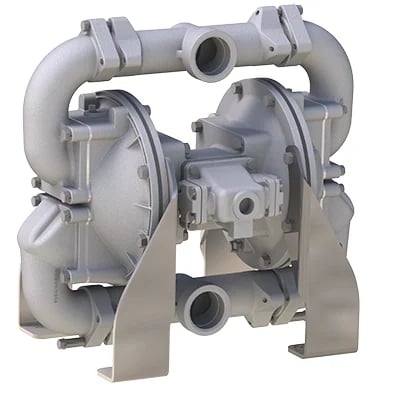

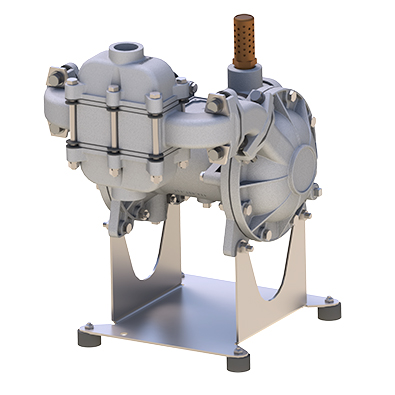

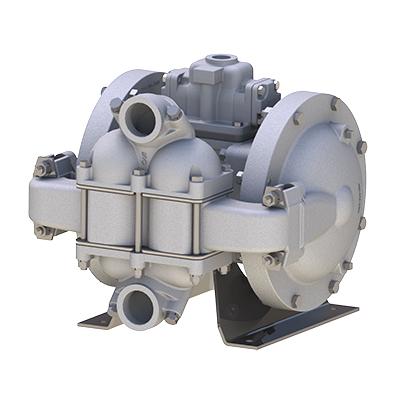

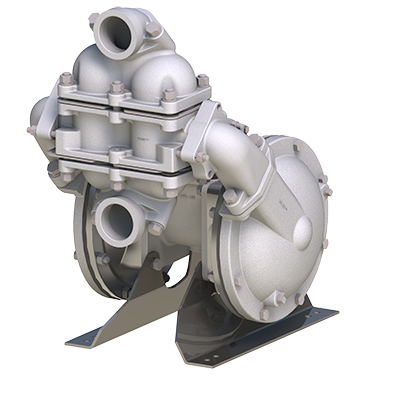

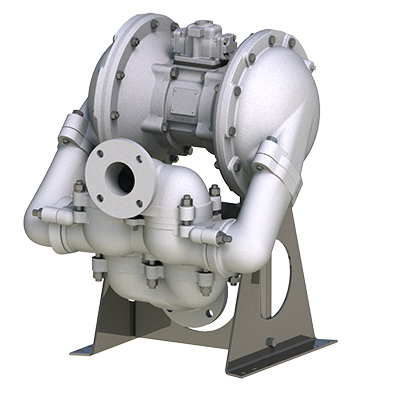

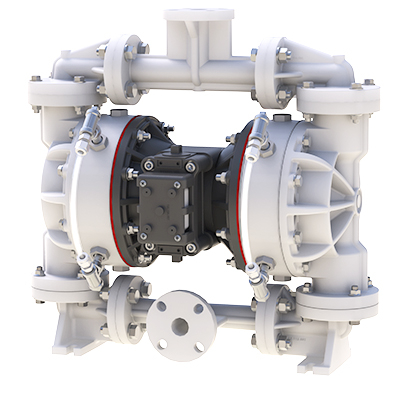

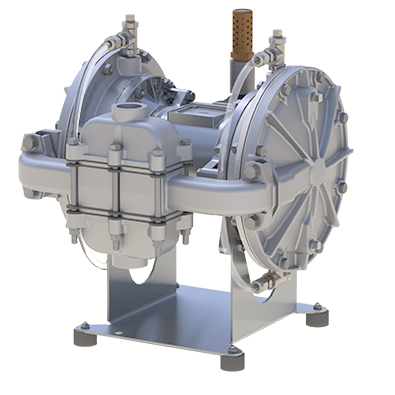

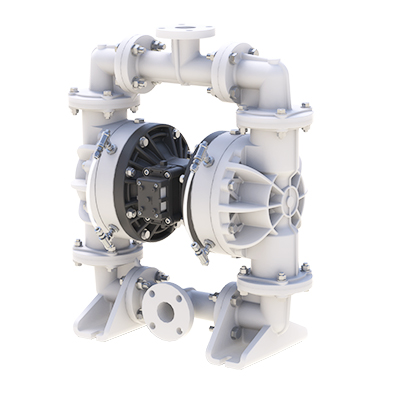

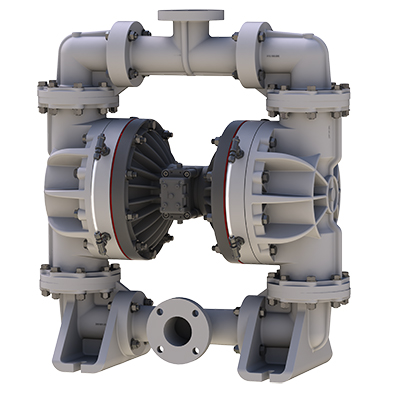

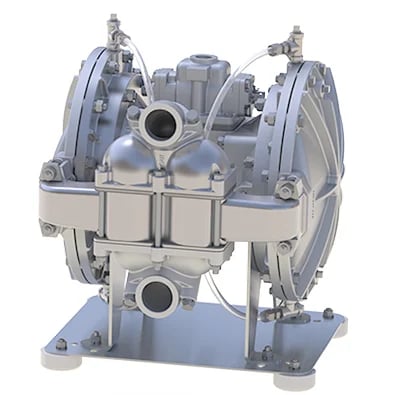

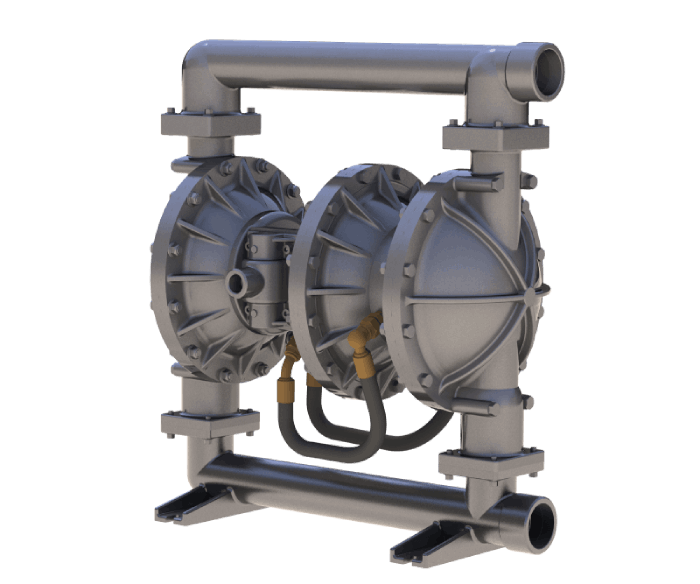

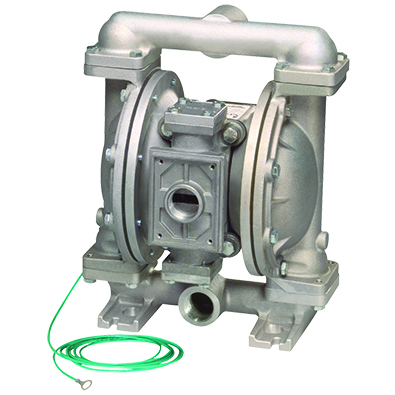

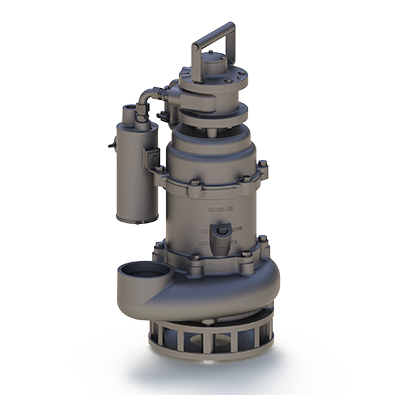

SANDPIPER G-Series | GAS OPERATED DOUBLE DIAPHRAGM (GODD)

Traditional AODD pumps are designed for use with air only. Over the years, oil and gas operators have opted to power their diaphragm pumps with easily accessible natural gas. The application of AODD pumps driven by natural gas created a unique set of safety requirements that previously did not exist.

In 2003, SANDPIPER recognized the need and partnered with the Canadian Standards Association (CSA®) to lead the development of the first-ever safety certification for Gas Operated Double Diaphragm (GODD) pumps. CSA Certified GODD pumps are designed and tested to be powered by natural gas when installed according to the certification and local requirements. SANDPIPER is the only GODD pump manufacturer that offers a full range of CSA Blue Star (ANSI LC6) / Blue Flame (Canadian Technical Letter R-14) Certified pumps from ½" to 3" sizes.

Our G-Series Dual Power pump line carries the most stringent certifications for safety and reliability for oil and gas applications and has been used extensively across midstream and upstream applications.

- Lube oil transfer

- Glycol recirculation/heat trace

- Flare knockout

- Glycol transfer/water make-up

- Sump/general transfer

- Tank bottom recirculation/transfer

- Utility/general transfer

- Separators and knockout drums

- General-duty spill cleanup

- Diesel fuel transfer

- Seawater pump for drilling mud make-up

- Produced water/condensate transfer

- Cellar pump-out and mud transfer

.png?width=660&height=510&name=Cognito%20Front%20view%20(1).png)