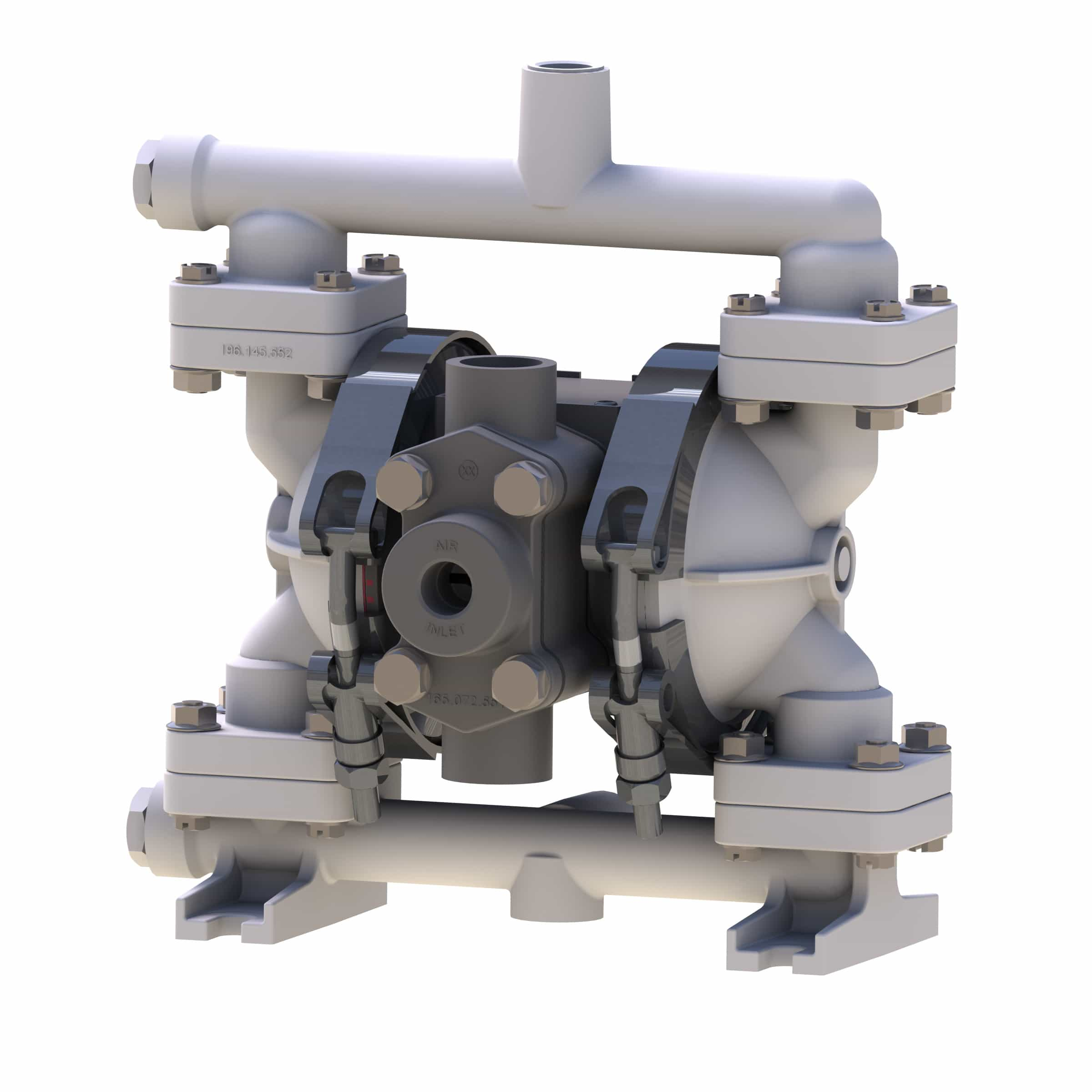

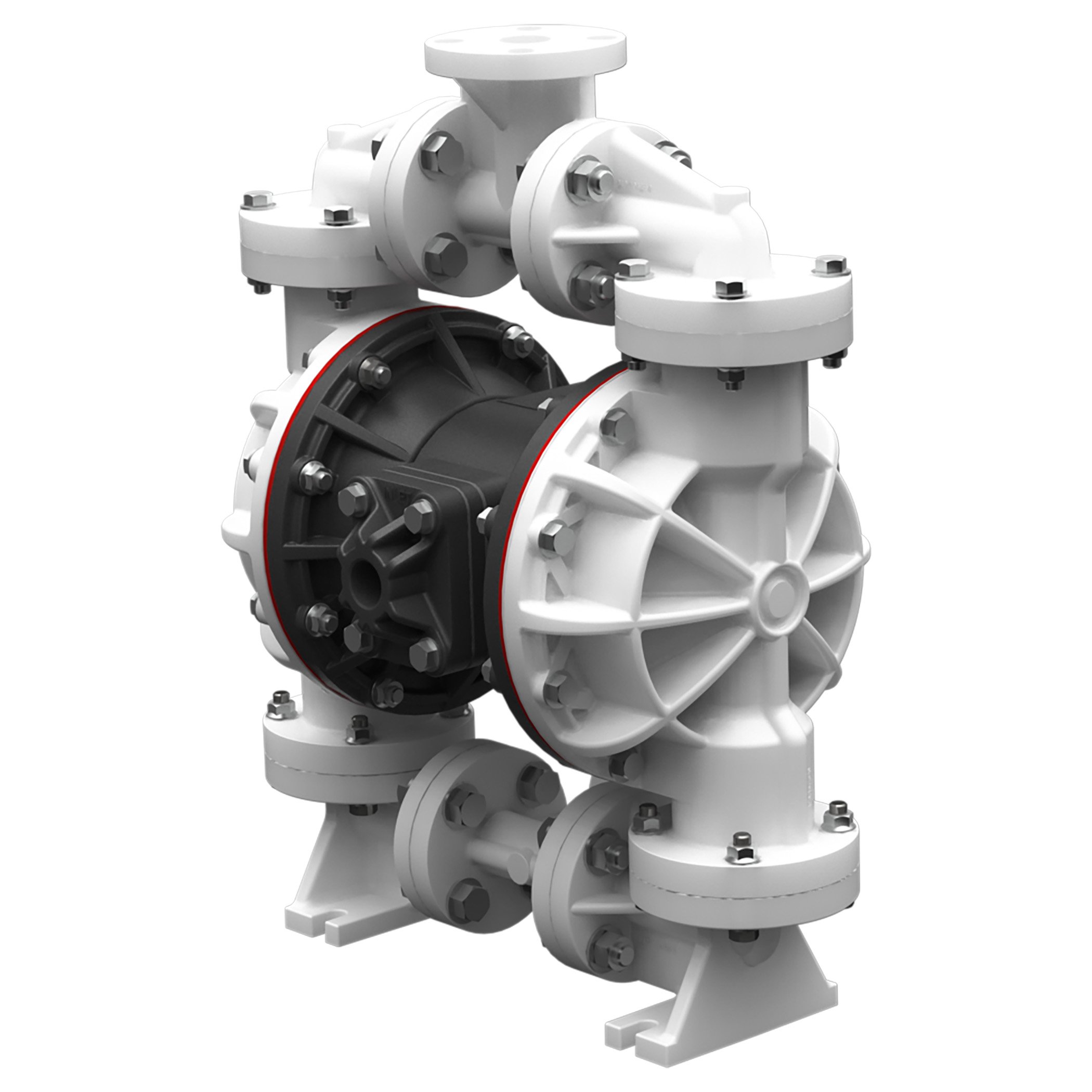

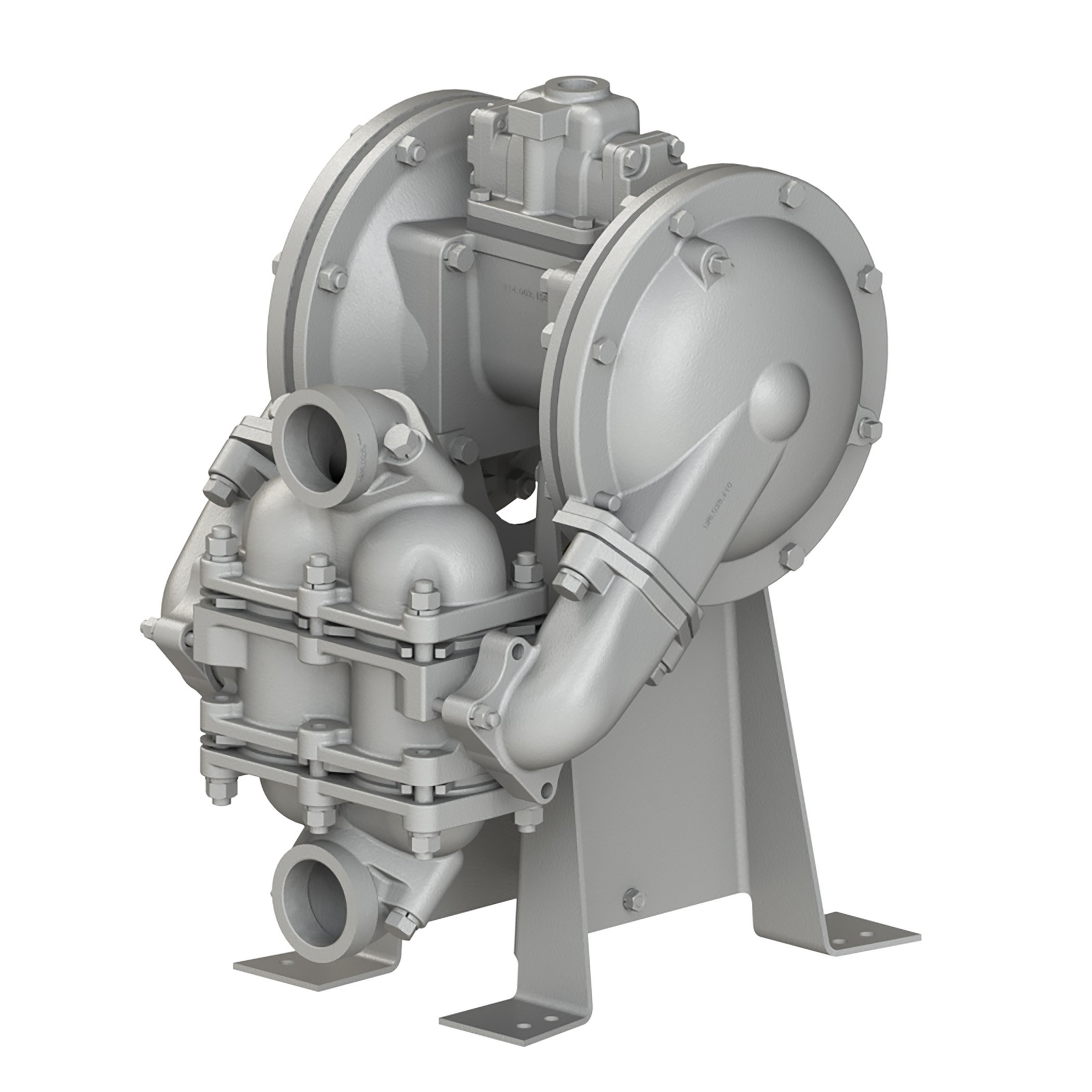

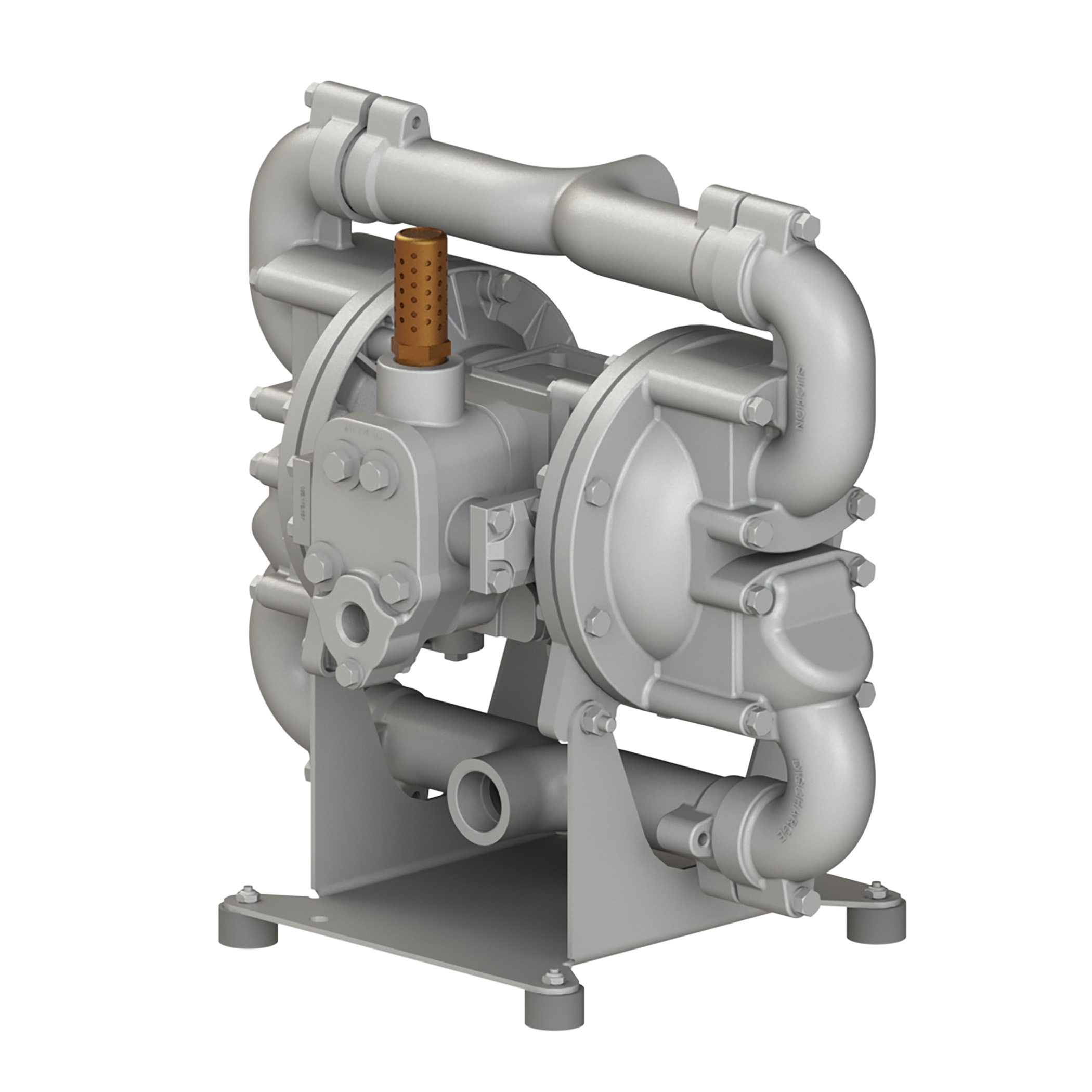

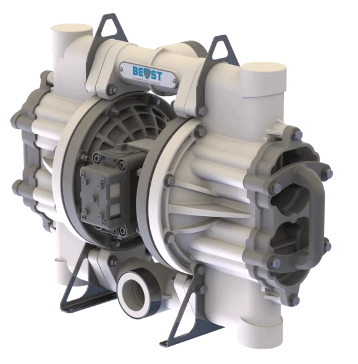

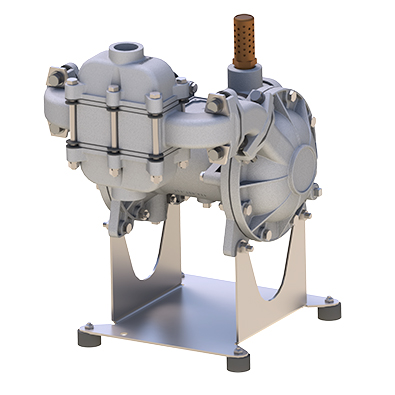

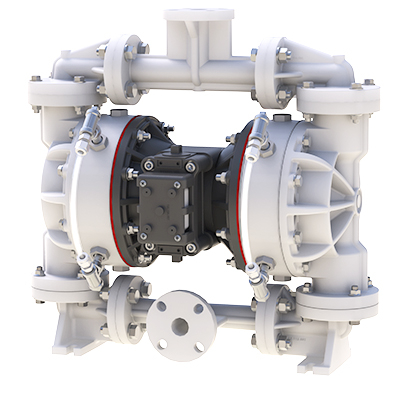

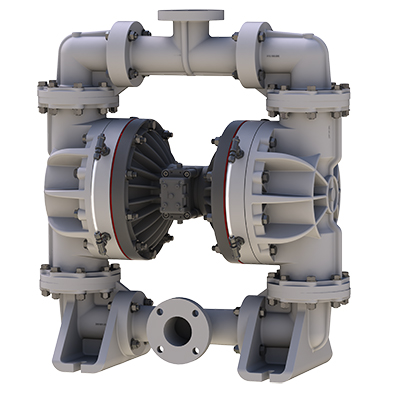

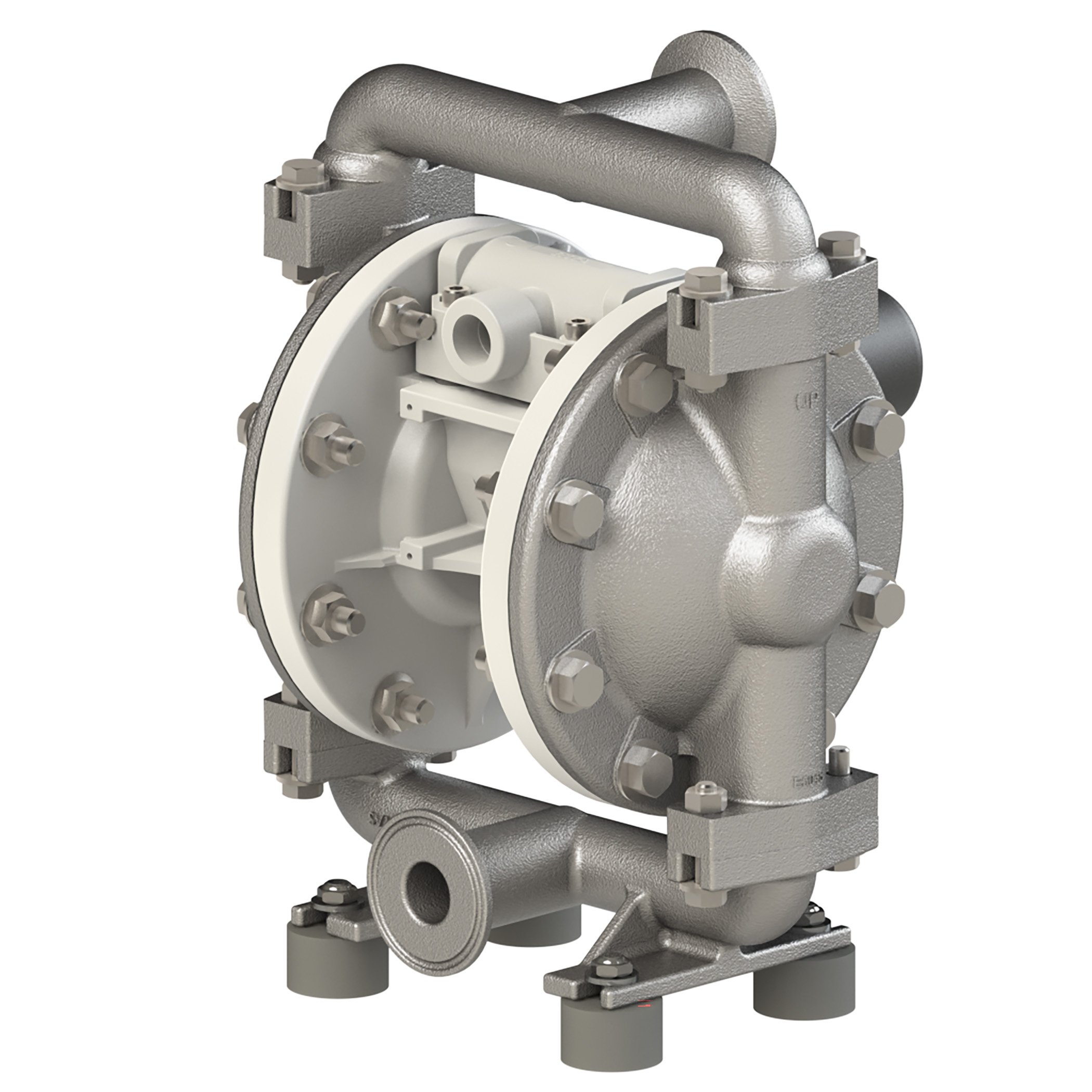

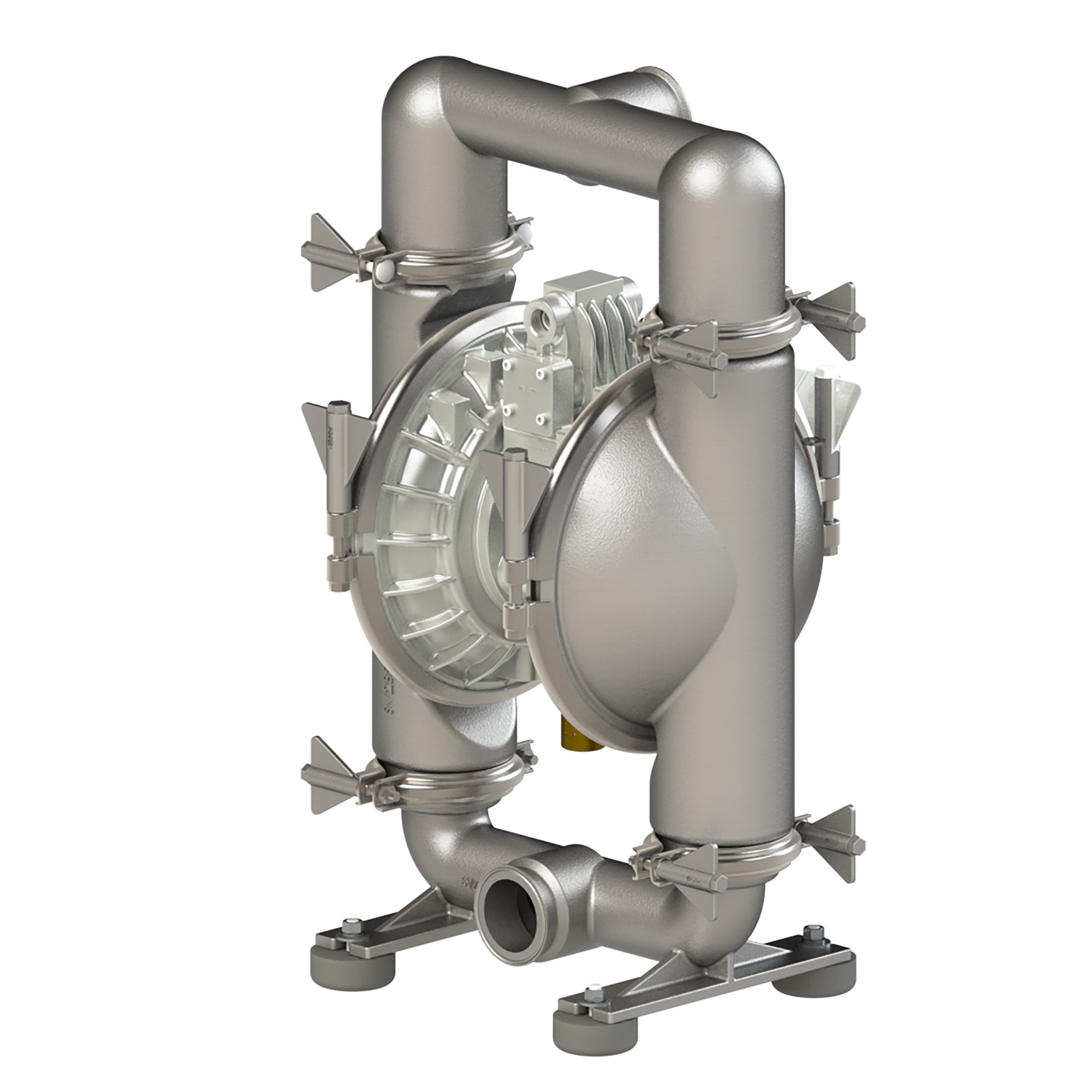

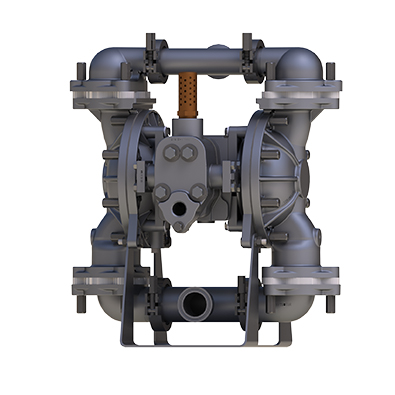

HEAVY DUTY FLAP, METALLIC AND NON-METALLIC

Recommended for abrasive slurries, non-suspended solids and line-size solids

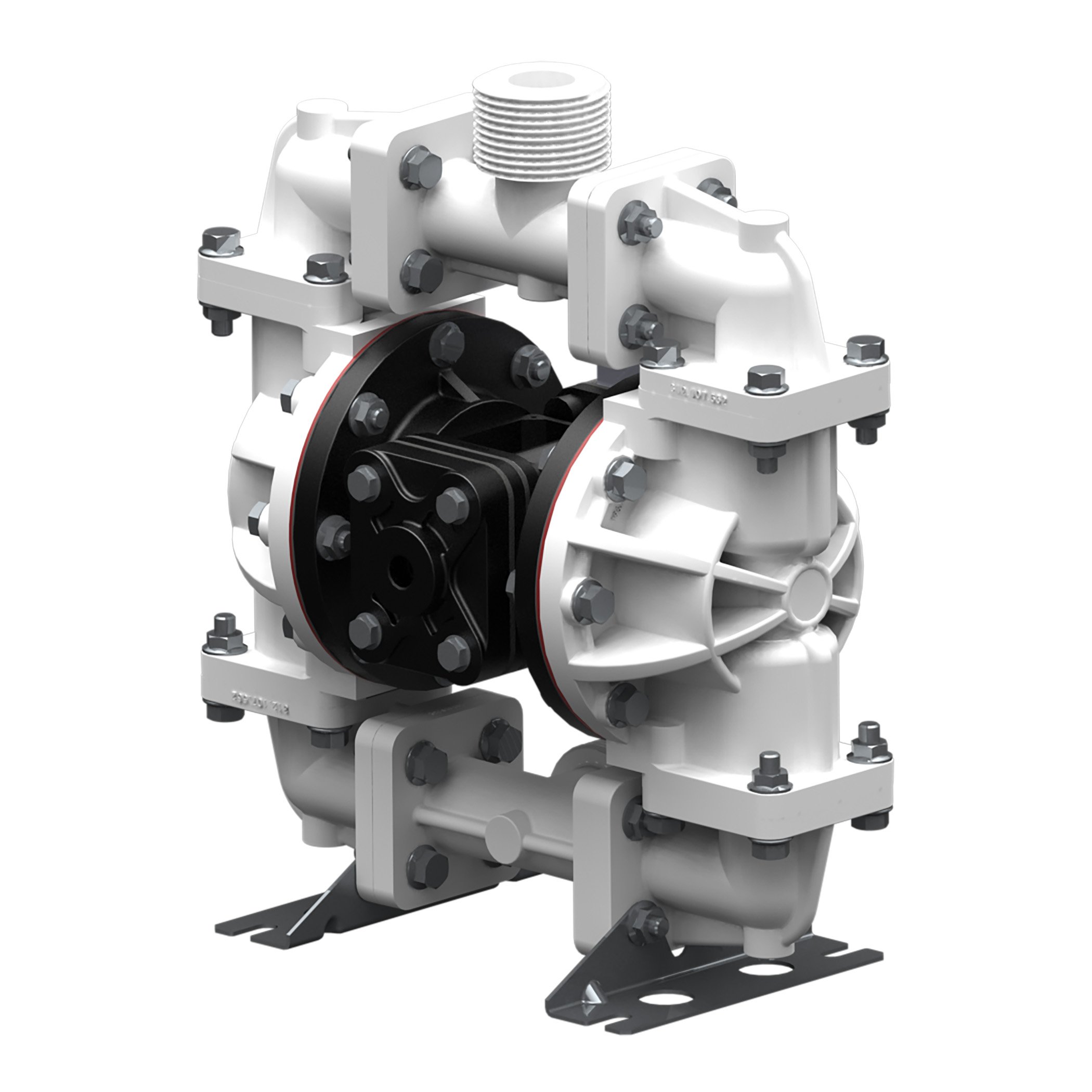

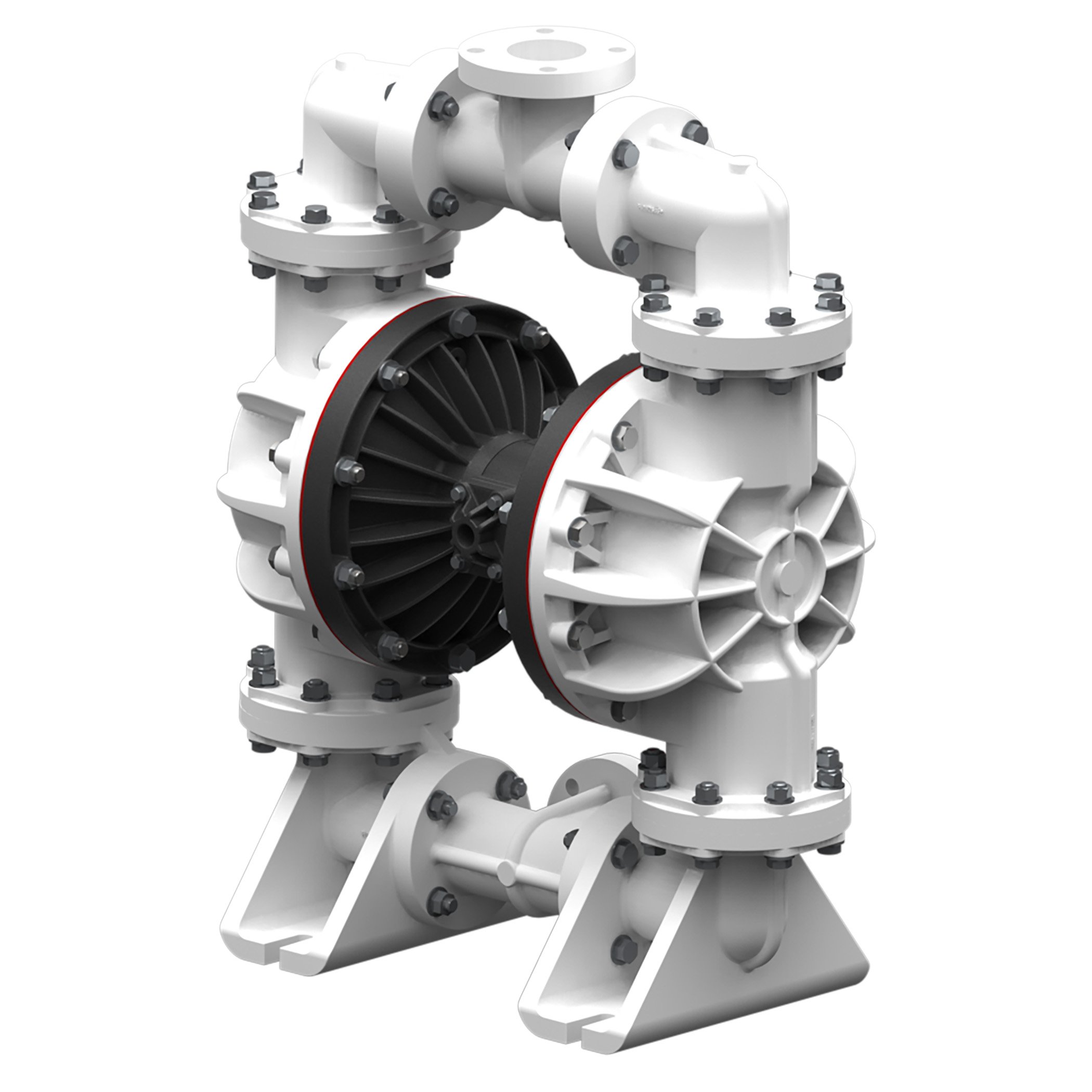

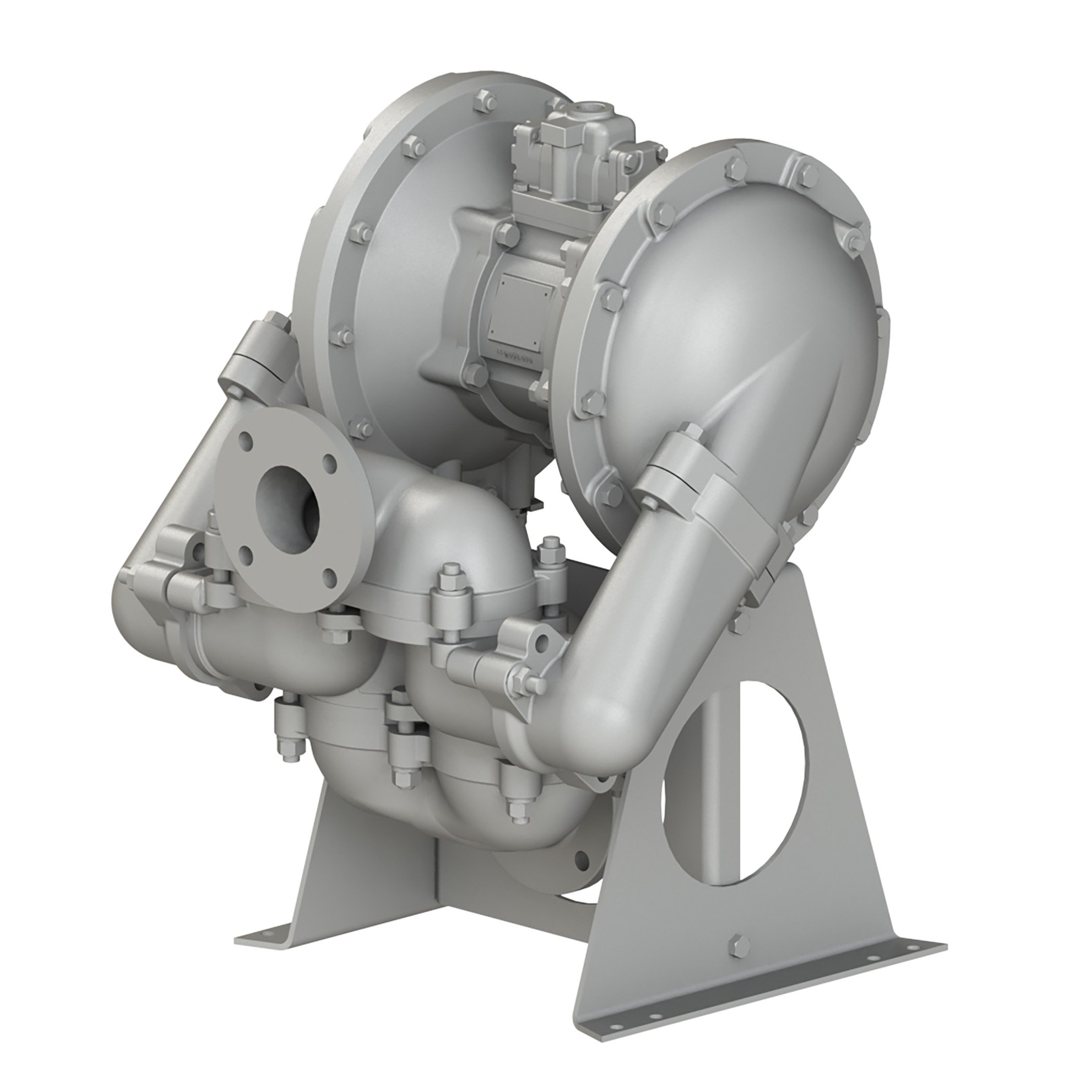

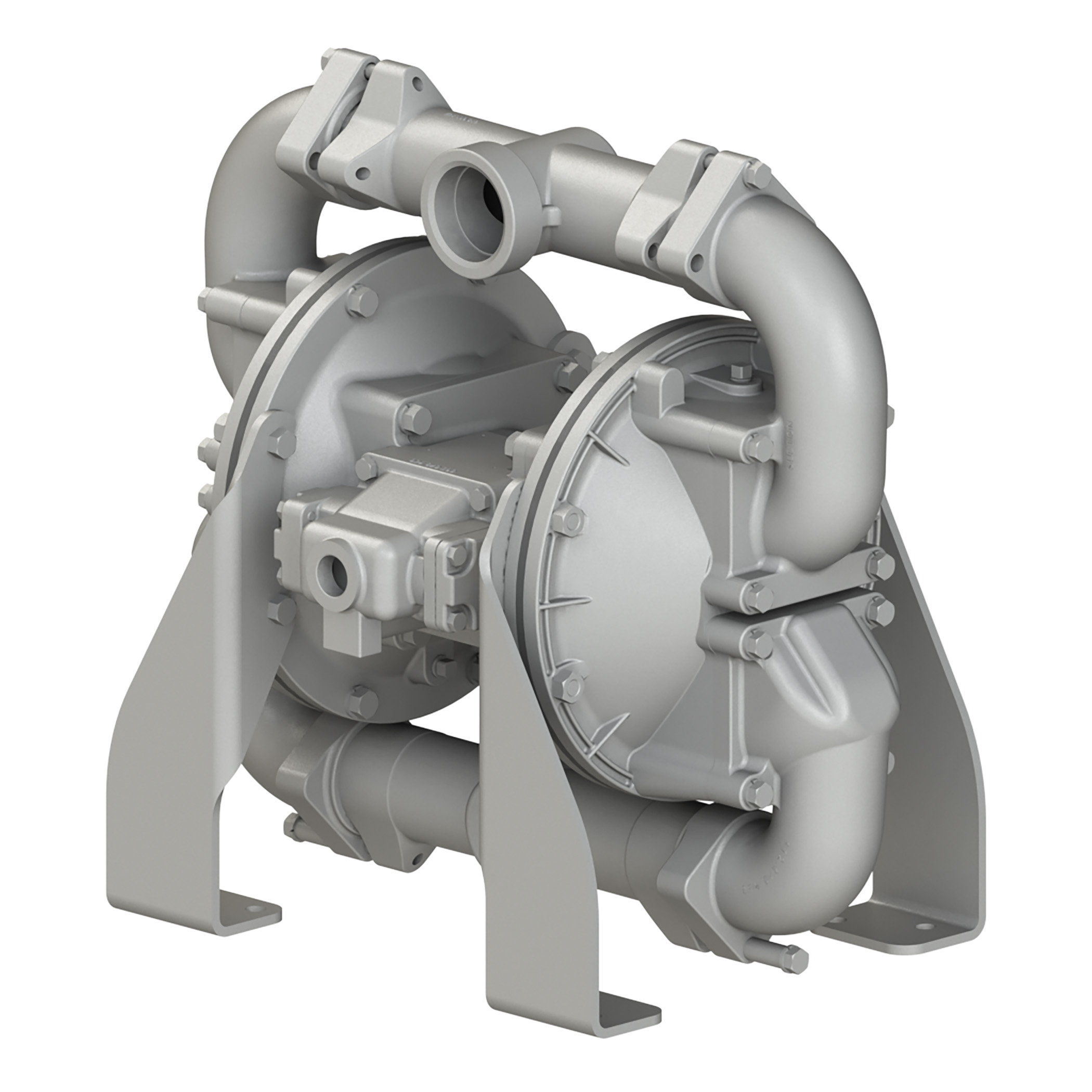

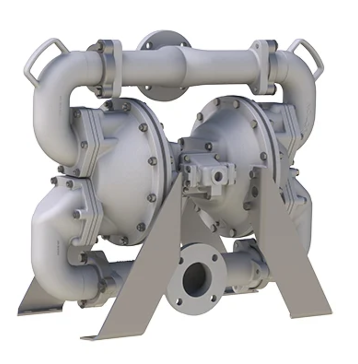

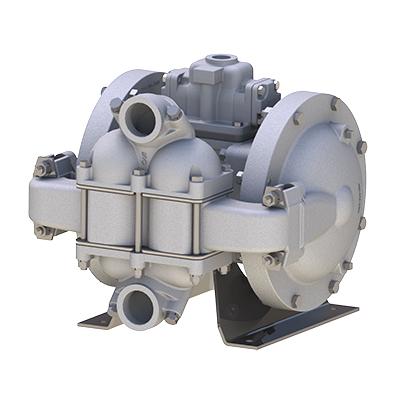

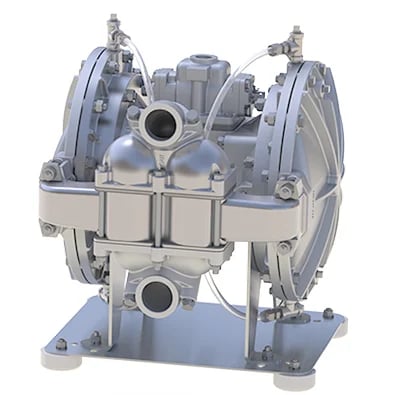

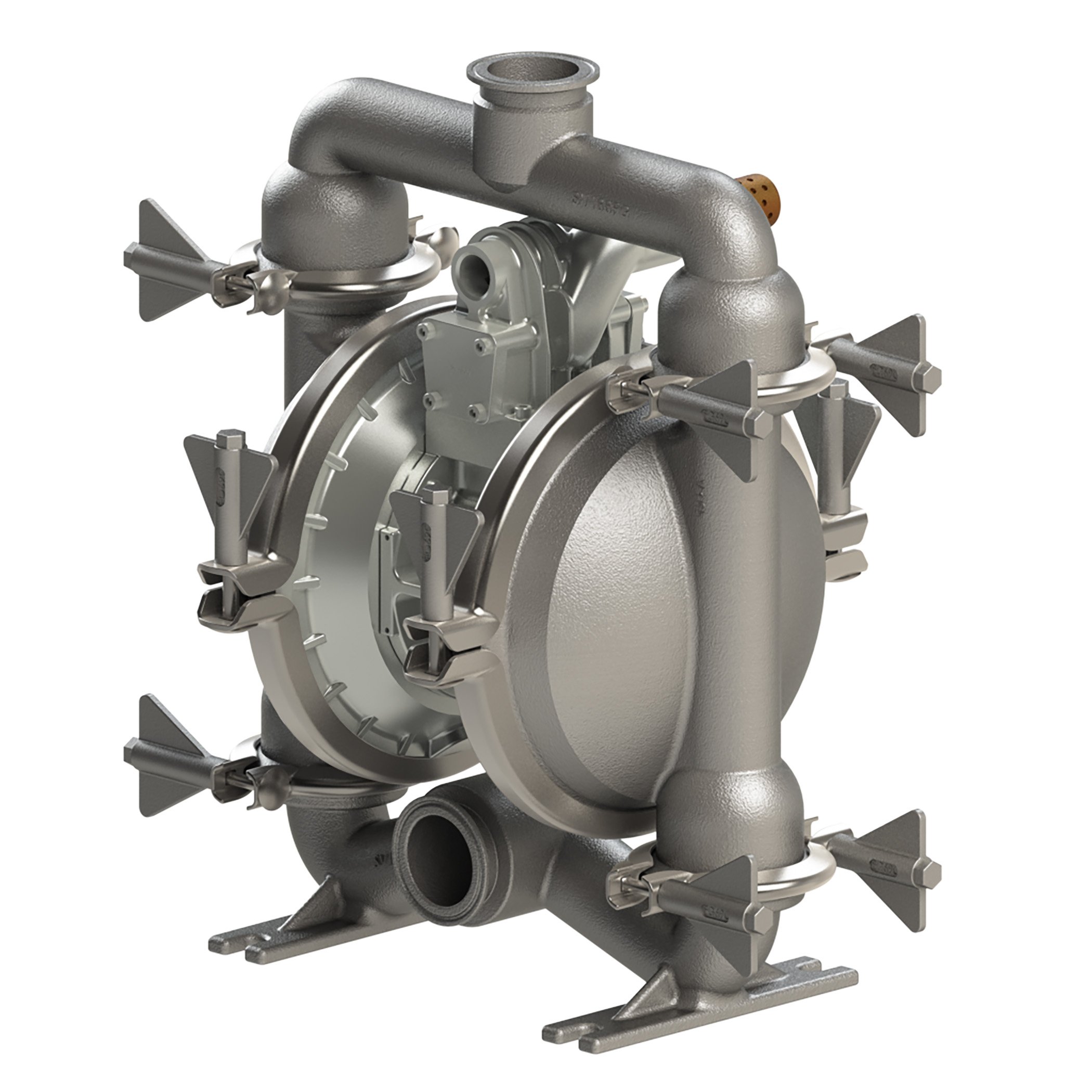

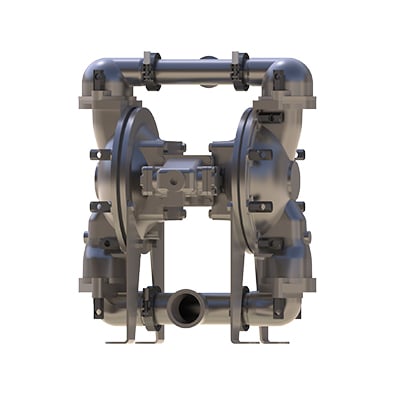

HEAVY DUTY BALL, METALLIC

Ideal for thin-to-highly viscous fluids and small solids-laden fluids

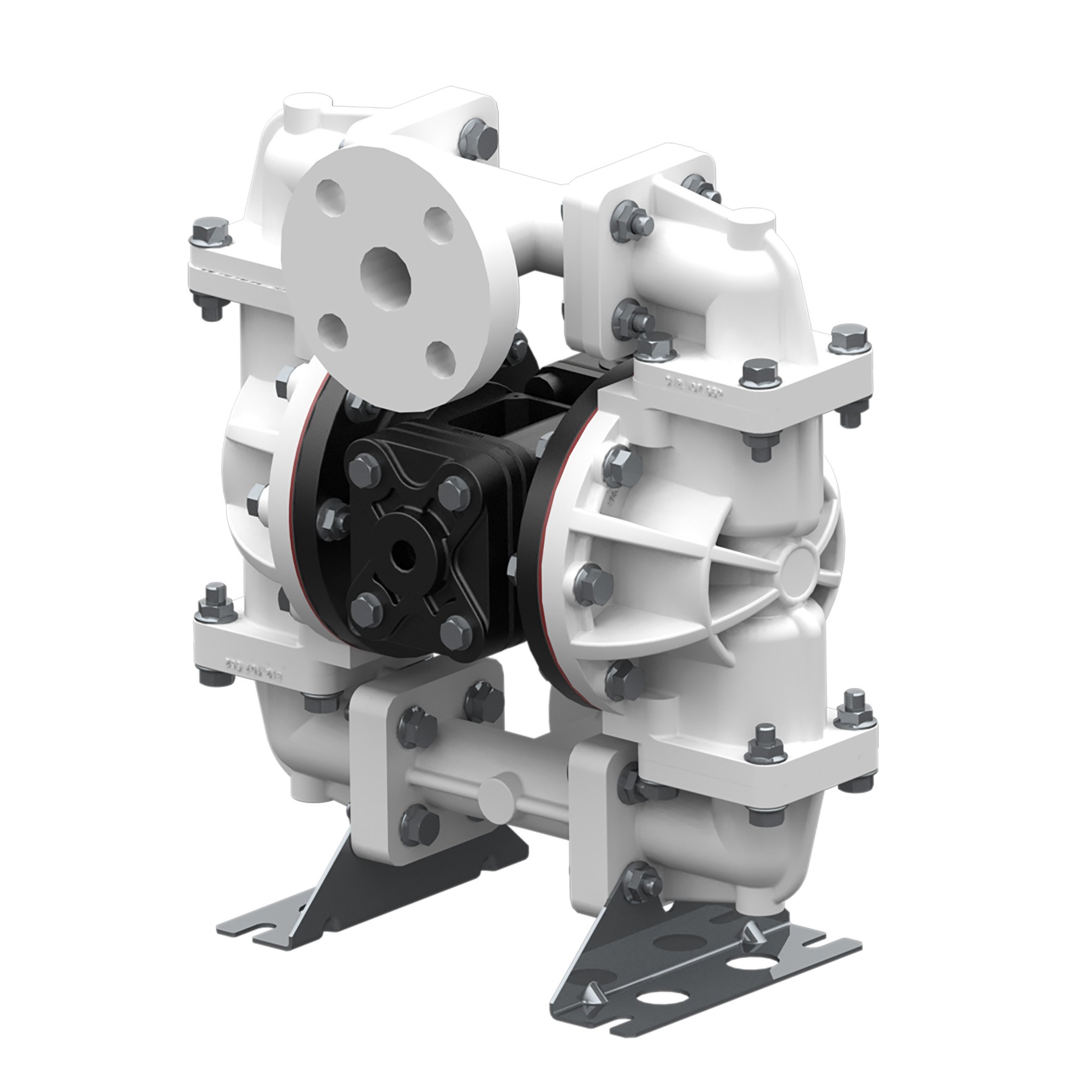

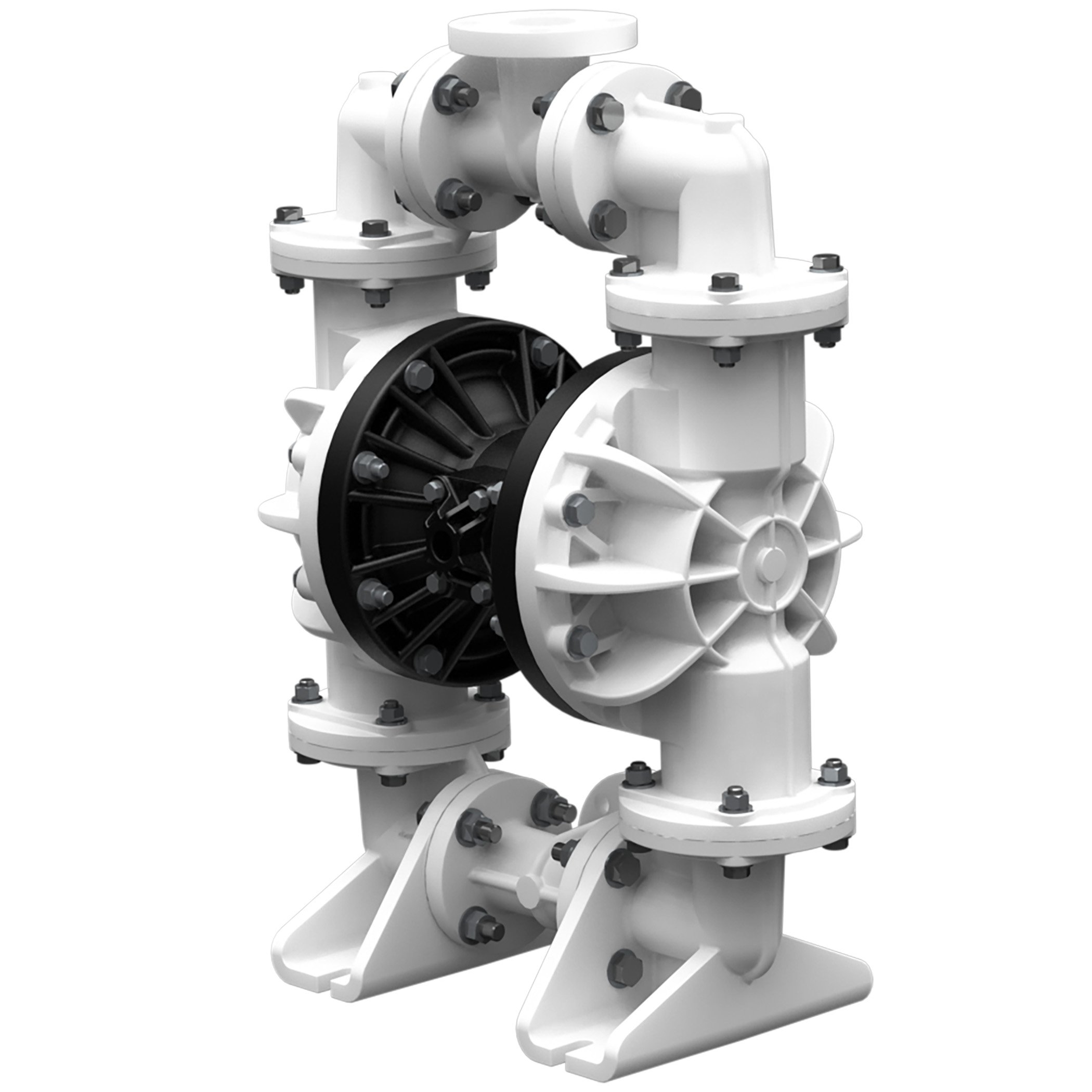

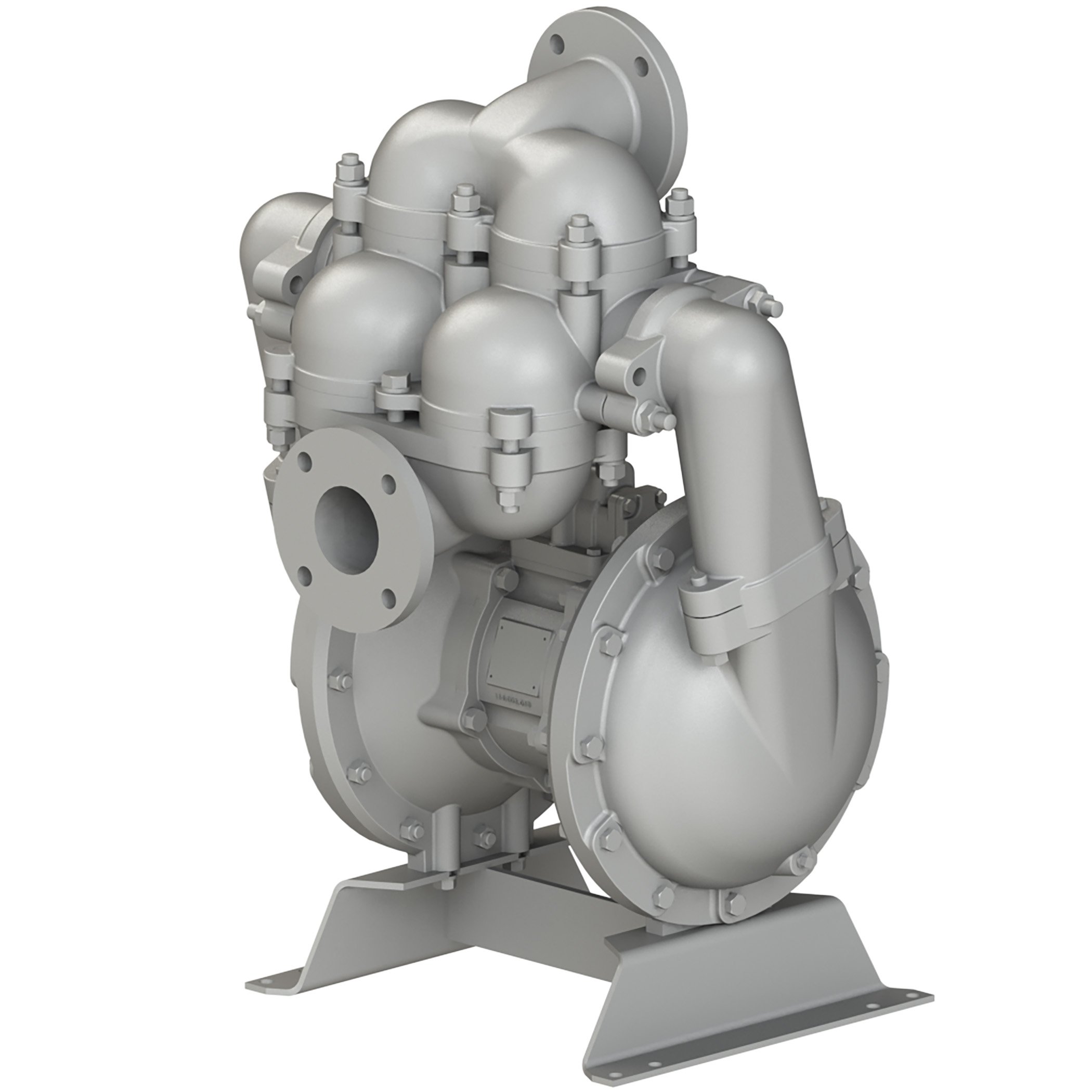

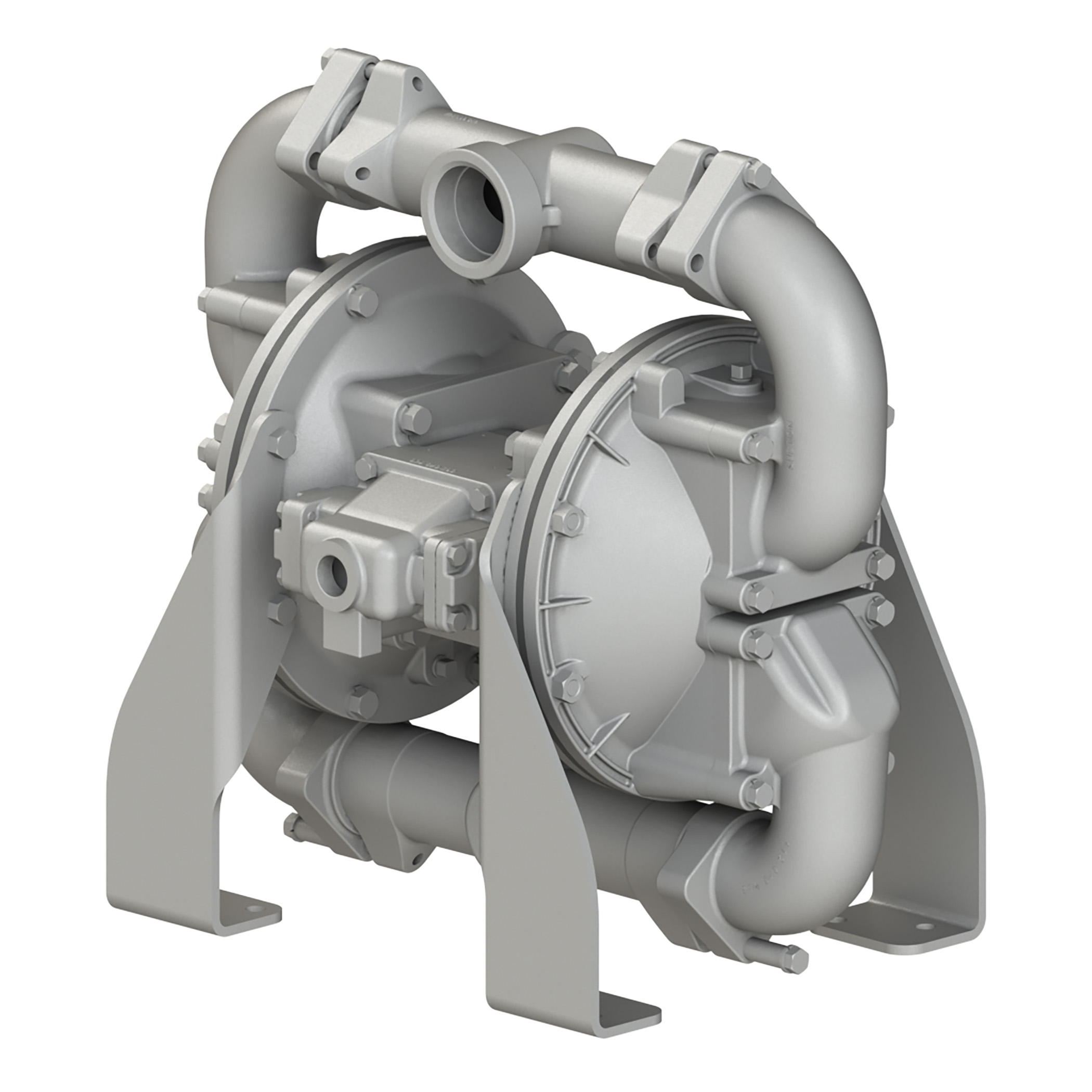

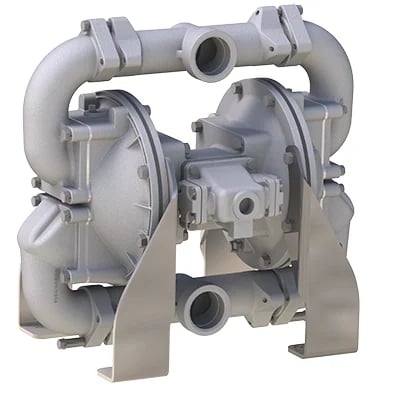

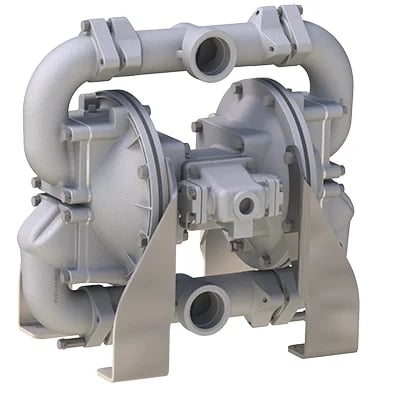

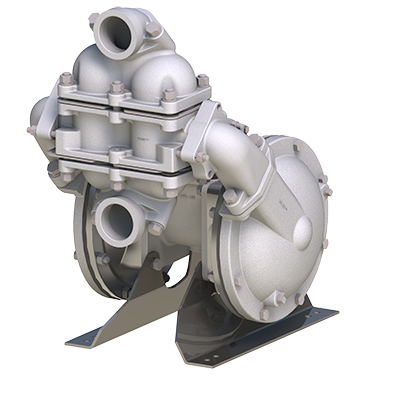

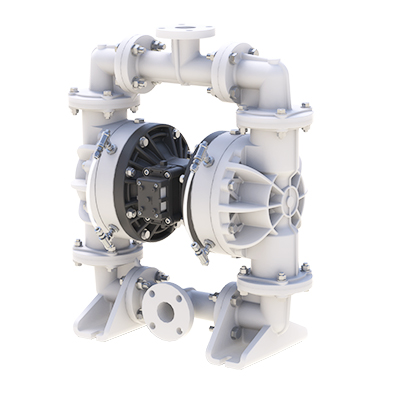

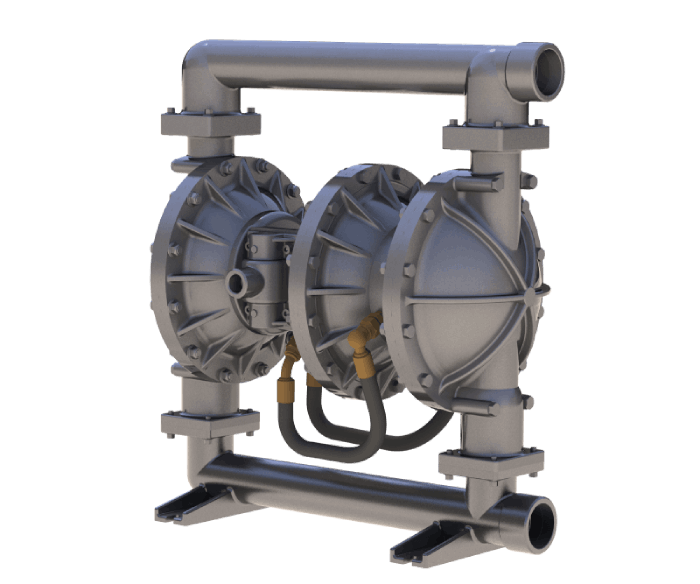

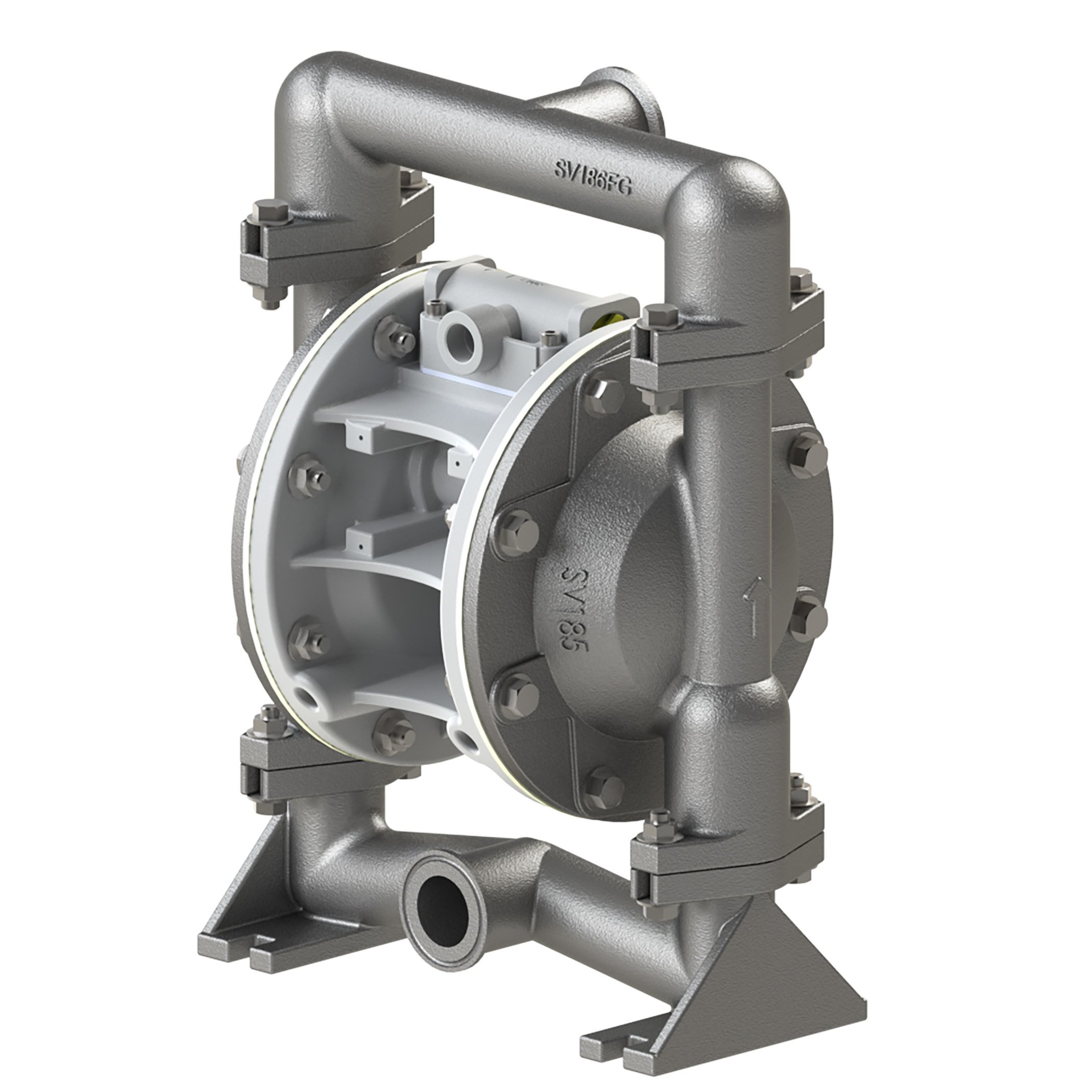

STANDARD DUTY BALL, METALLIC AND NON-METALLIC

Best for intermittent / on-demand, portable, moderately abrasive fluids, and suspended solids

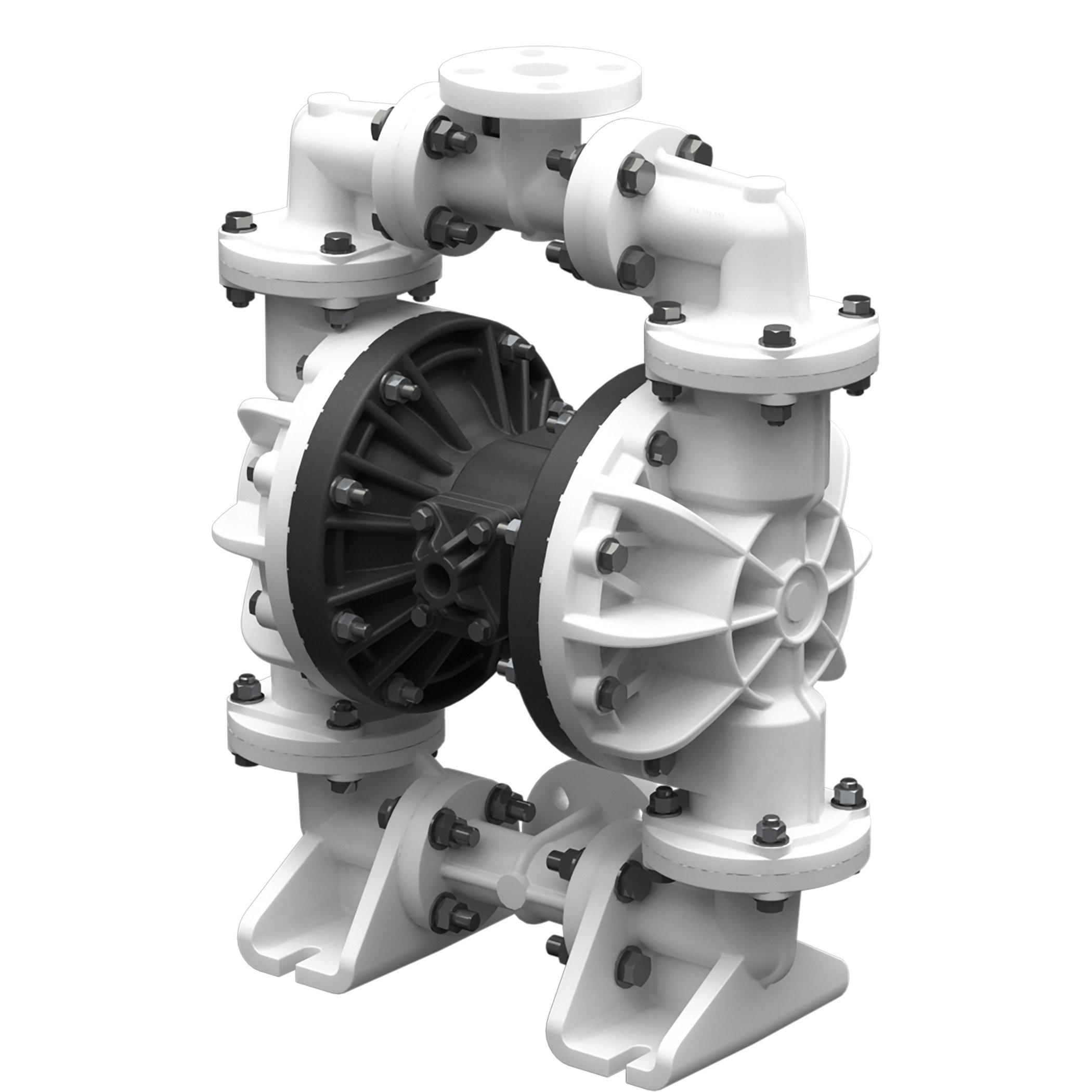

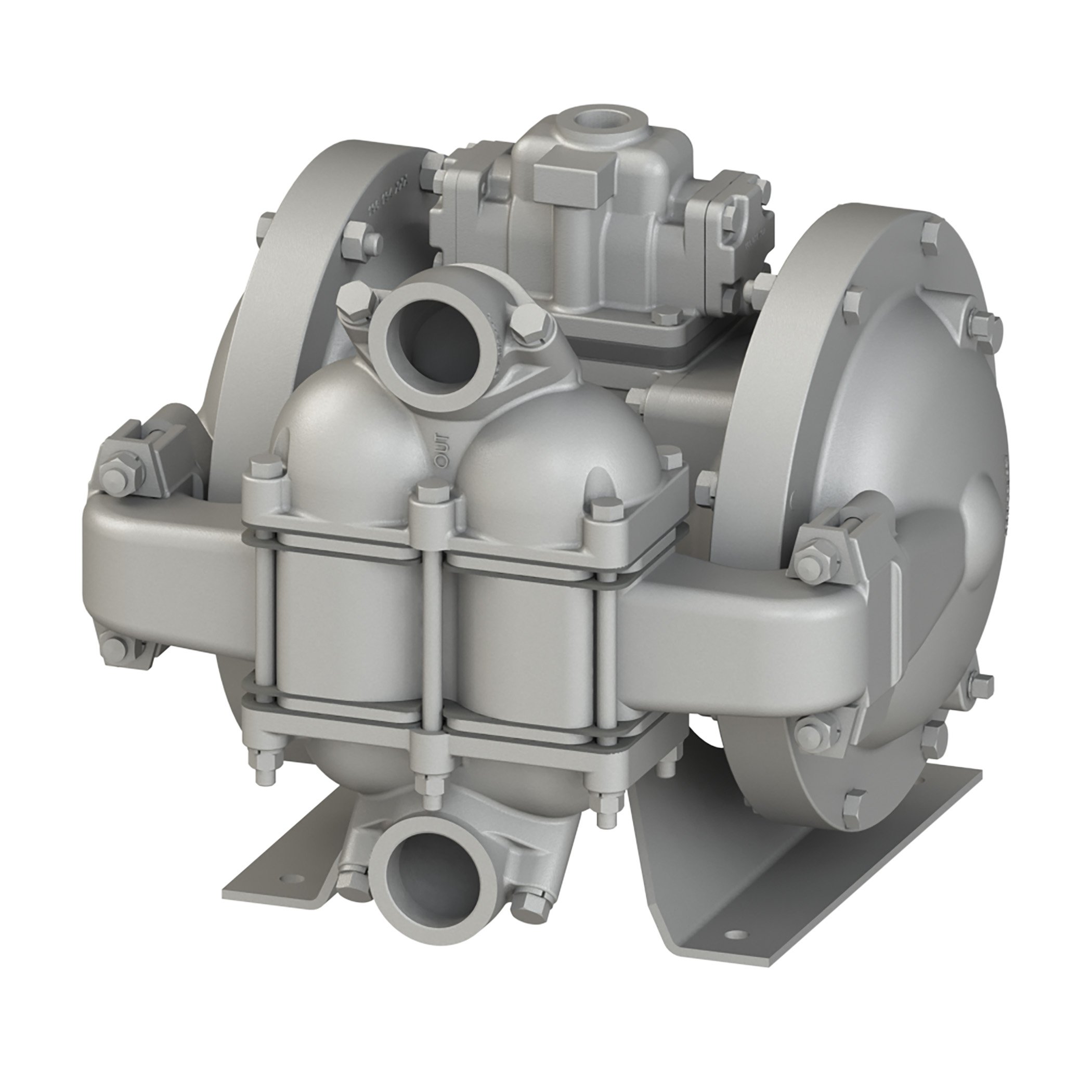

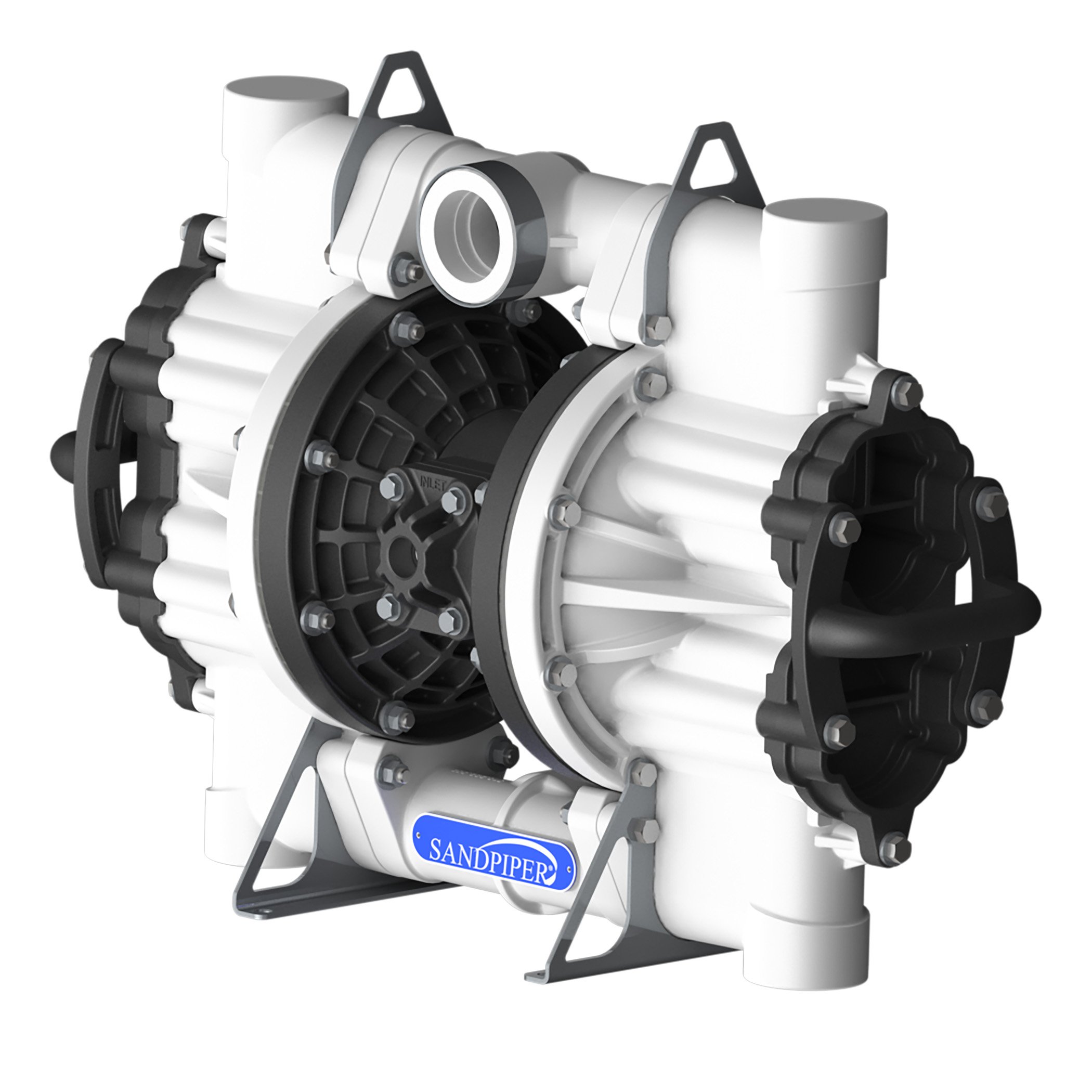

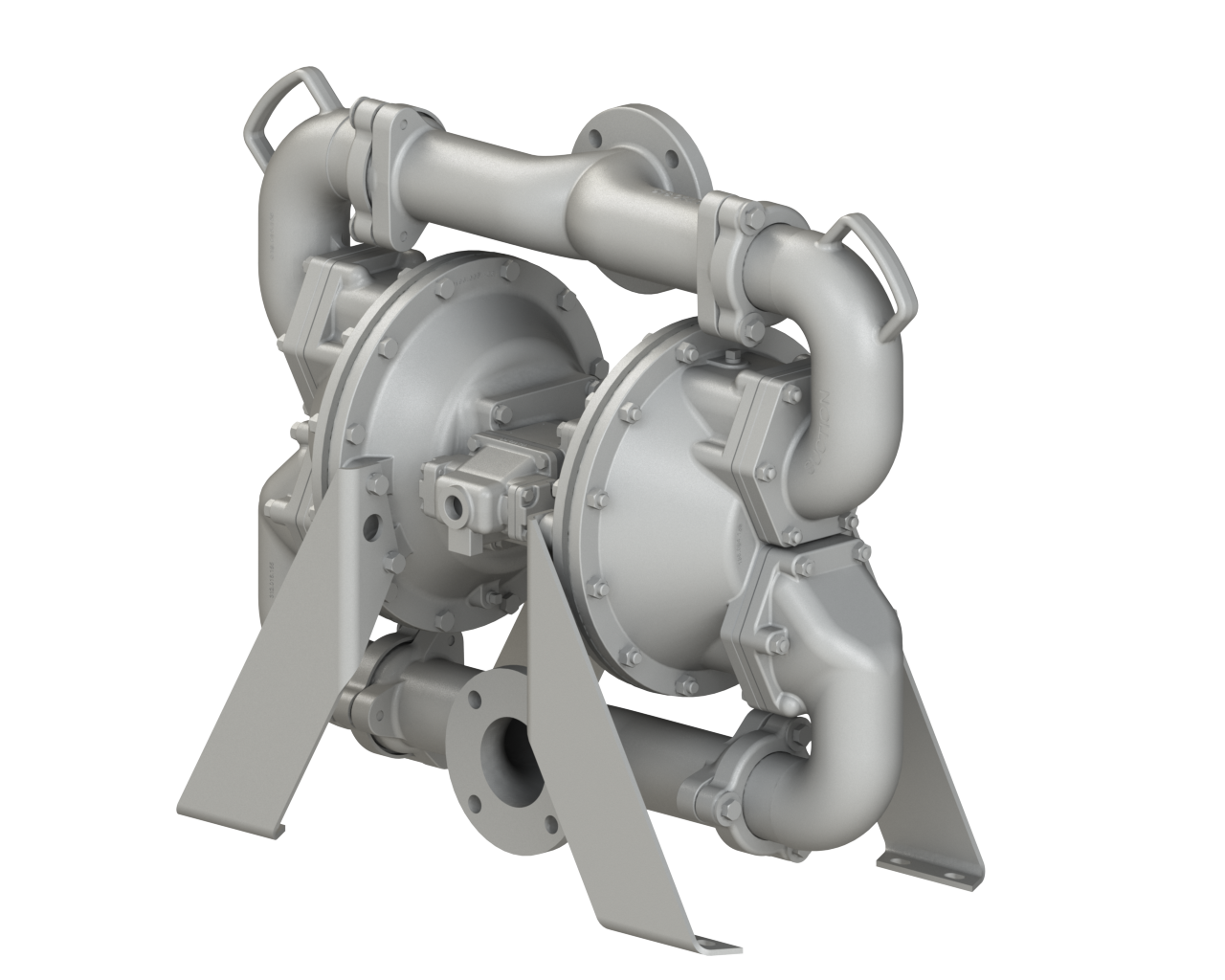

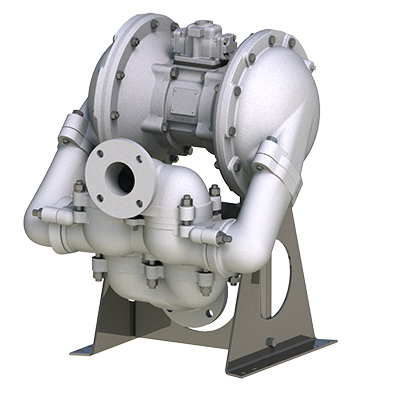

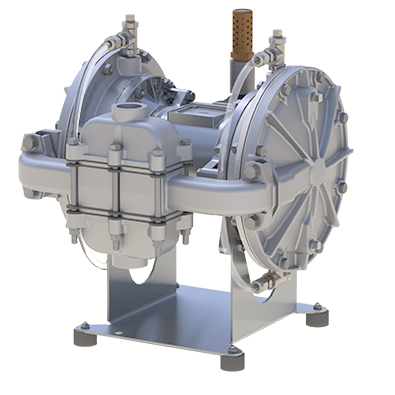

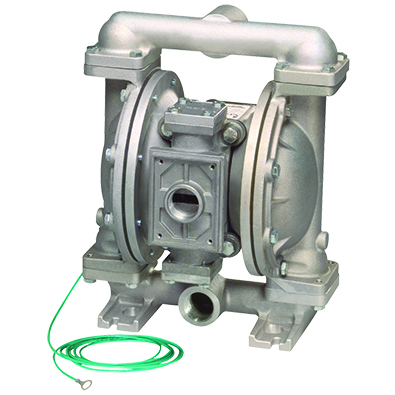

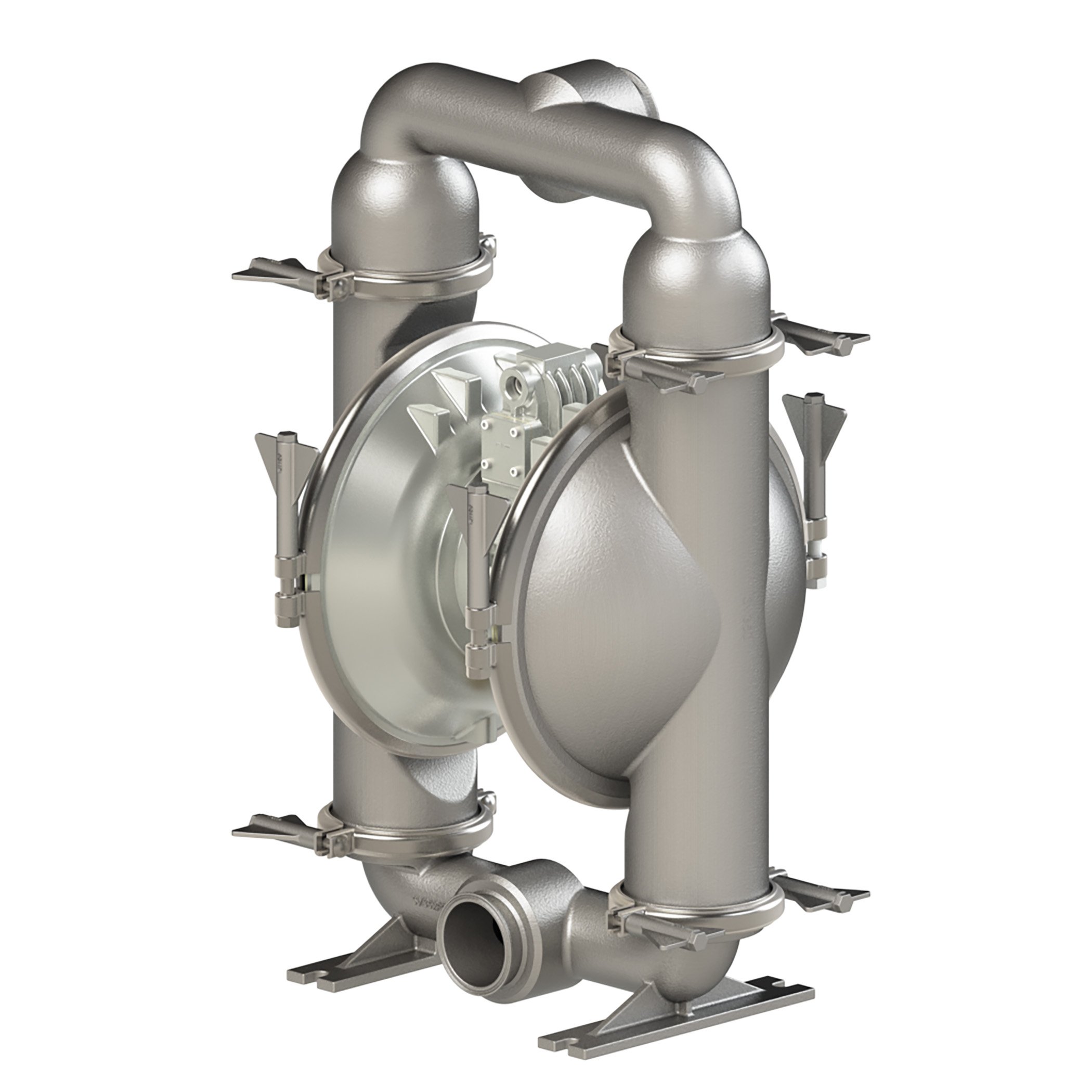

CONTAINMENT DUTY, METALLIC AND NON-METALLIC

Optimal for highly corrosive and hazardous chemical fluid applications

OTHER PUMPS

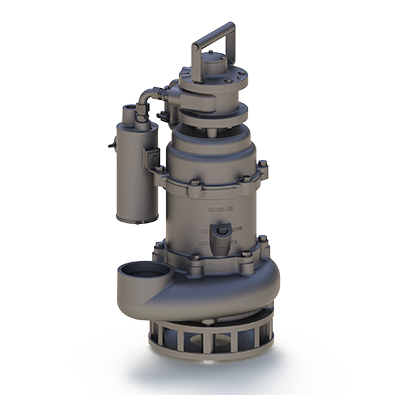

FDA and Sanitary | High Pressure | Gas-Operated | Submersible | Electric Operated (EODD)

.png?width=358&height=364&name=Rectangle%20pump%20(1).png)

.png?width=660&height=510&name=Cognito%20Front%20view%20(1).png)

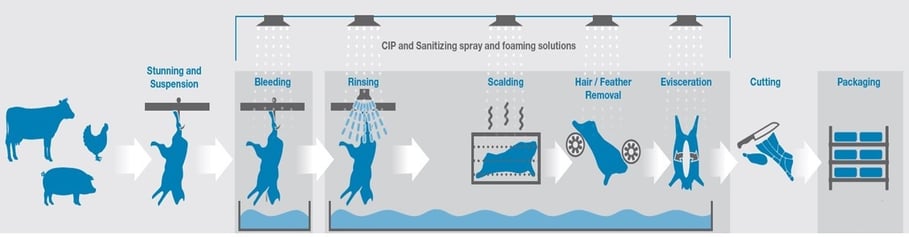

The first SANDPIPER heavy-duty flap valve air-operated double-diaphragm (AODD) pump was invented by Mr. Warren Rupp in 1968, and by the early 1970s, it had already established itself as the workhorse in meat and poultry processing facilities because of its unique ability to pass large solids that would clog other pumps. In fact, the SANDPIPER heavy-duty flap became known as the animal “blood pump” because it could easily pump the solids that would find their way into the blood collection areas.

The first SANDPIPER heavy-duty flap valve air-operated double-diaphragm (AODD) pump was invented by Mr. Warren Rupp in 1968, and by the early 1970s, it had already established itself as the workhorse in meat and poultry processing facilities because of its unique ability to pass large solids that would clog other pumps. In fact, the SANDPIPER heavy-duty flap became known as the animal “blood pump” because it could easily pump the solids that would find their way into the blood collection areas.

.png)

.png)

.png)

.png)

.png)