ELECTRIC OPERATED DOUBLE DIAPHRAGM (EODD) PUMPS

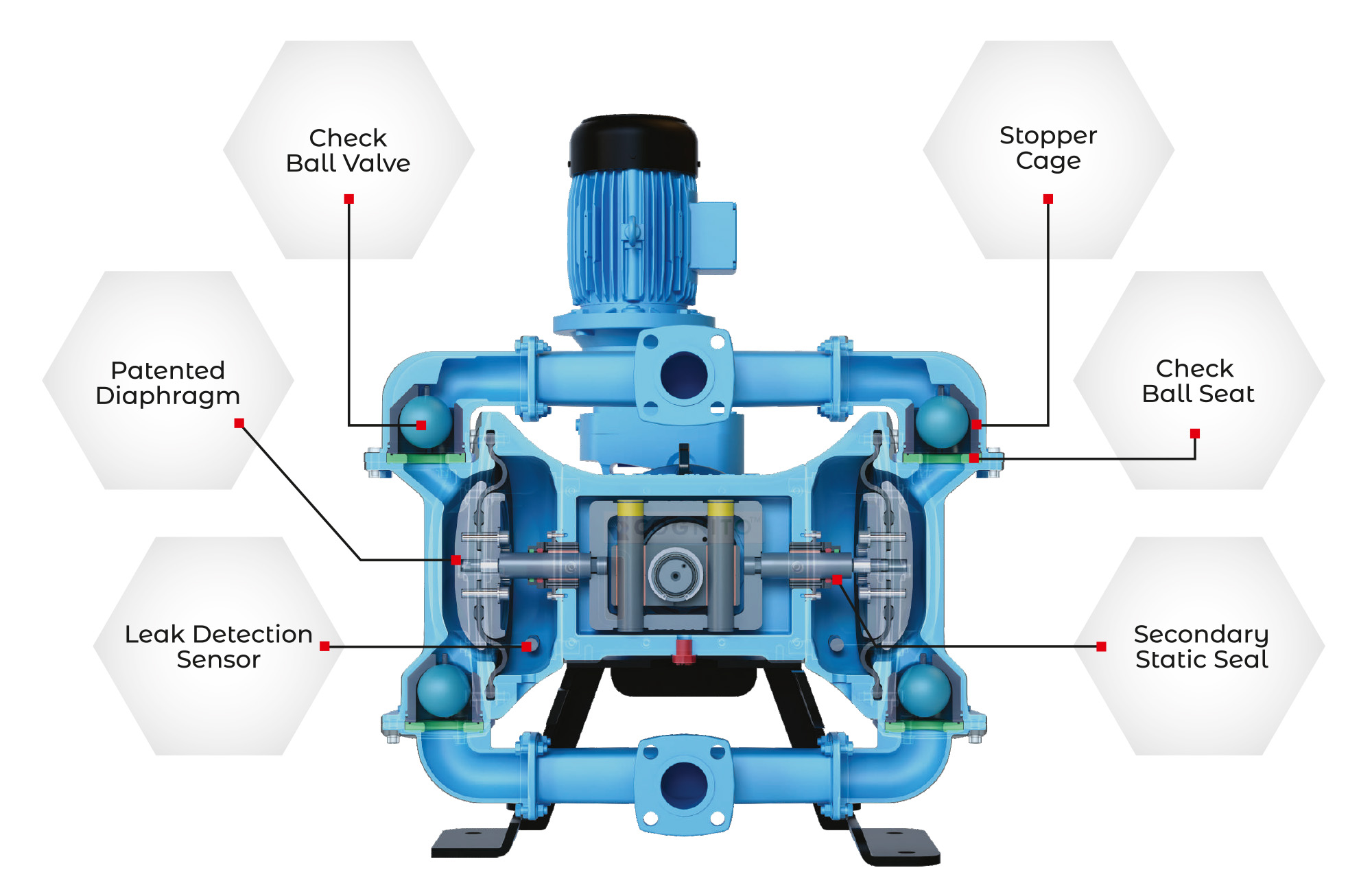

CognitoTM EODD is a Smart, IoT-enabled Electrically Operated Double Diaphragm pump. It is designed and developed while partnering with our customers, and by leveraging our 30 years of expertise in design and engineering and in-depth application knowledge in fluid technology. The CognitoTM EODD is engineered and designed with a robust mechanism to satisfy every customer's demands for increased production efficiency and lower total cost of ownership while facilitating the smooth handling of a variety of fluids and slurries.

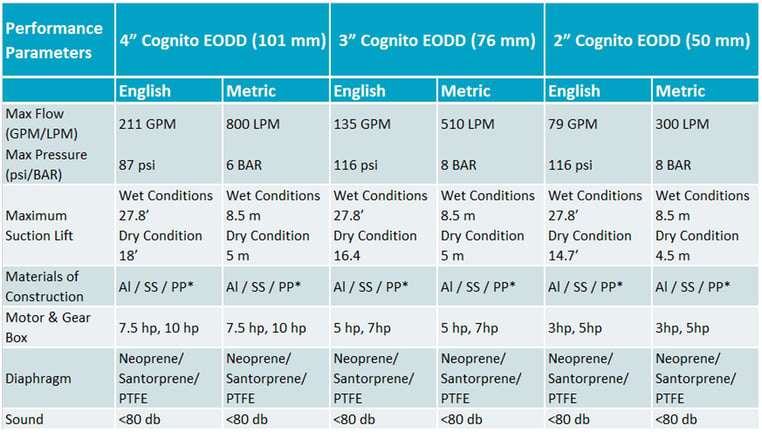

Pump Specification

Request Information

The Cognito Advantage

This IoT-enabled platform helps you to connect, monitor and analyze your equipment remotely and enables you to make better and faster decisions to optimize your equipment performance and improve overall process efficiency. Its advanced smart technology creates an instant alert for any abnormality that may occur.

Application and Industries Served

IOT Enabled

The Cognito platform helps you to connect, monitor and analyze your equipment remotely and enables you to make better and faster decisions to optimize your equipment performance and improve overall process efficiency. Its advanced smart technology creates an instant alert for any abnormality to enhance the process.

SCHEDULE A CONSULTATION

Let’s Discuss Your Project

You have complex industrial challenges and we have problem-solving expertise to find the solutions that fit your needs. When you schedule a consultation with SANDPIPER, we will:

- Have a conversation about the challenges you’re facing

- Tell you about other customers we’ve worked with and give you data that proves the effectiveness of our pumps

- Set up an in-person meeting if warranted

- Find the products that will perfectly match your application requirements

Scheduling a consultation will give you the information you need to make a decision about selecting an AODD pump manufacturer you can partner with who will provide safe, reliable and energy-efficient solutions. Fill out the form to schedule your consultation.